Supercritical carbon dioxide injection device for thick oil mechanism experiment

A carbon dioxide and injection device technology, which is applied in the direction of mechanical equipment, production fluid, wellbore/well components, etc., can solve the problems of slow feedback, limited gas volume, and inability to output gas in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

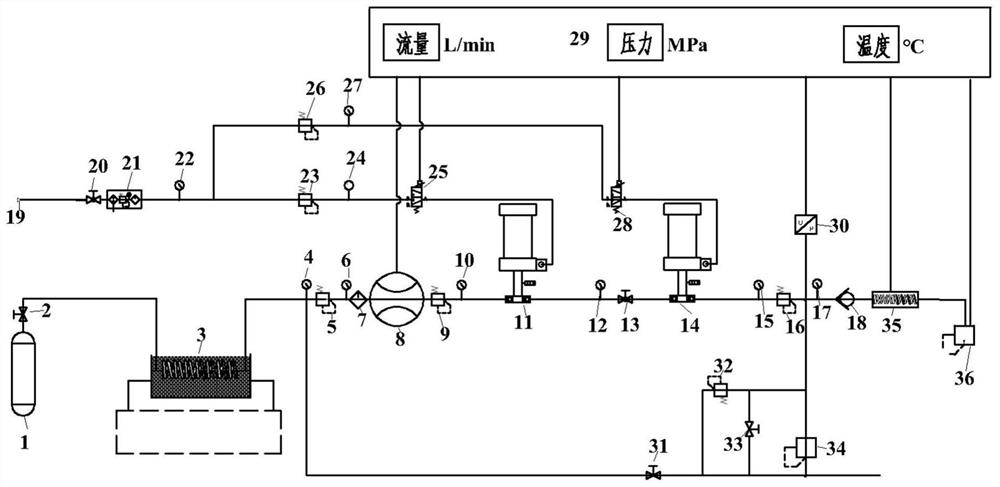

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] Such as figure 1 As shown, a supercritical carbon dioxide injection device for heavy oil mechanism experiment, including driving gas source injection device, air flow control device, safety protection device and control system 29;

[0028] The driving gas source injection device is connected with a first gas booster pump 11 and a second gas booster pump 14. The gas source input end of the first gas booster pump 11 and the gas source input end of the second gas booster pump 14 are all connected to Power compressed air source 19, shut-off valve and pressure gauge are arranged between the first gas booster pump 11 and power compressed air source 19, shut-off valve and pressure gauge are arranged between the second gas booster pump 14 and power compressed air source 19. surface;

[0029] The air flow control device includes a carbon dioxide gas source 1, a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com