Extrusion type Liangnong big cake production device

A production device and extrusion technology, which is applied in the direction of dough extruder, dough embossing machine, baking, etc., can solve the problems of cumbersome operation, long time-consuming, low efficiency, etc., and achieve expanded functionality, speed and convenience , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

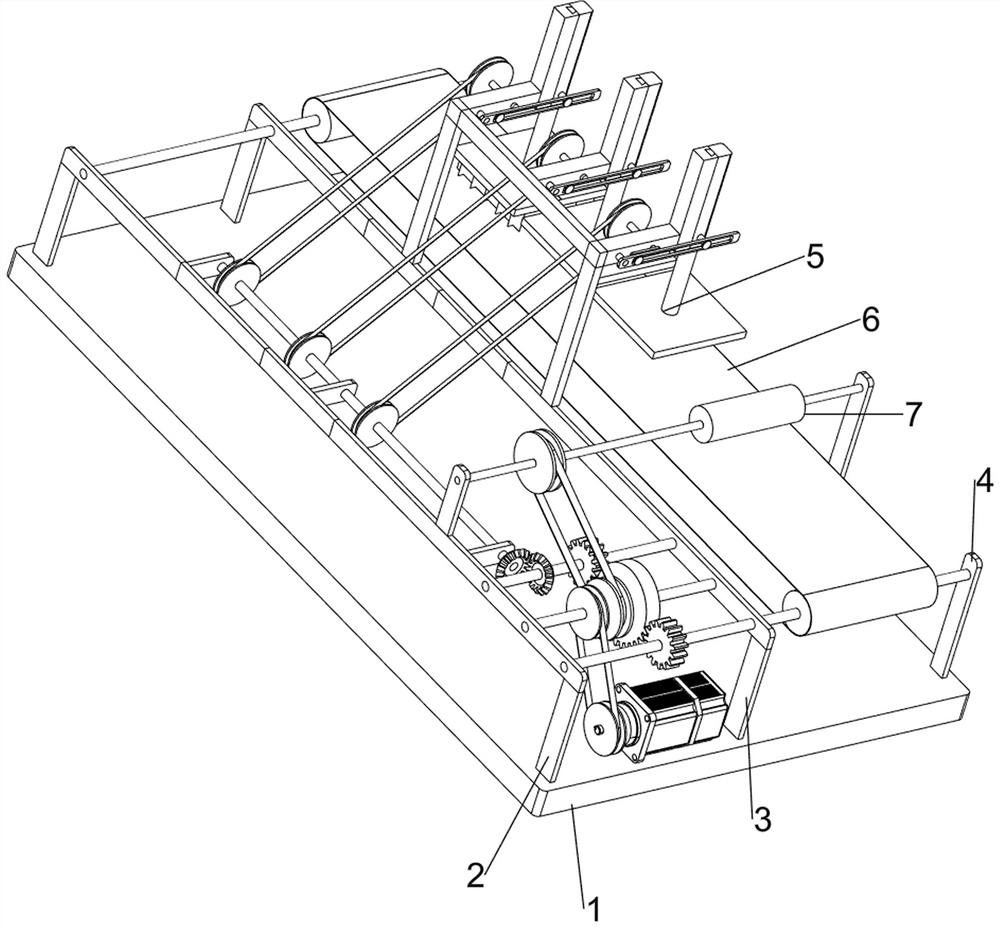

[0057] A kind of extruding type beam makes big cake production device, such as figure 1 As shown, it includes a base 1, a first support frame 2, a second support frame 3, a pillar 4, a circulation pressing mechanism 5 and a conveyor belt mechanism 6. The upper front side of the base 1 is provided with a first support frame 2, and There is a second support frame 3 in the middle, three pillars 4 are arranged on the upper rear side of the base 1 from left to right, the first support frame 2 and the second support frame 3 are provided with a circulation pressing mechanism 5, and the first support frame 2. A conveyor belt mechanism 6 is provided on the second support frame 3 and the pillar 4, and the conveyor belt mechanism 6 cooperates with the circulation pressing mechanism 5.

[0058] People rely on the form of making big cakes by hand, which cannot achieve convenient and efficient production. Therefore, people can use this device to produce big cakes. First, people prepare the ...

Embodiment 2

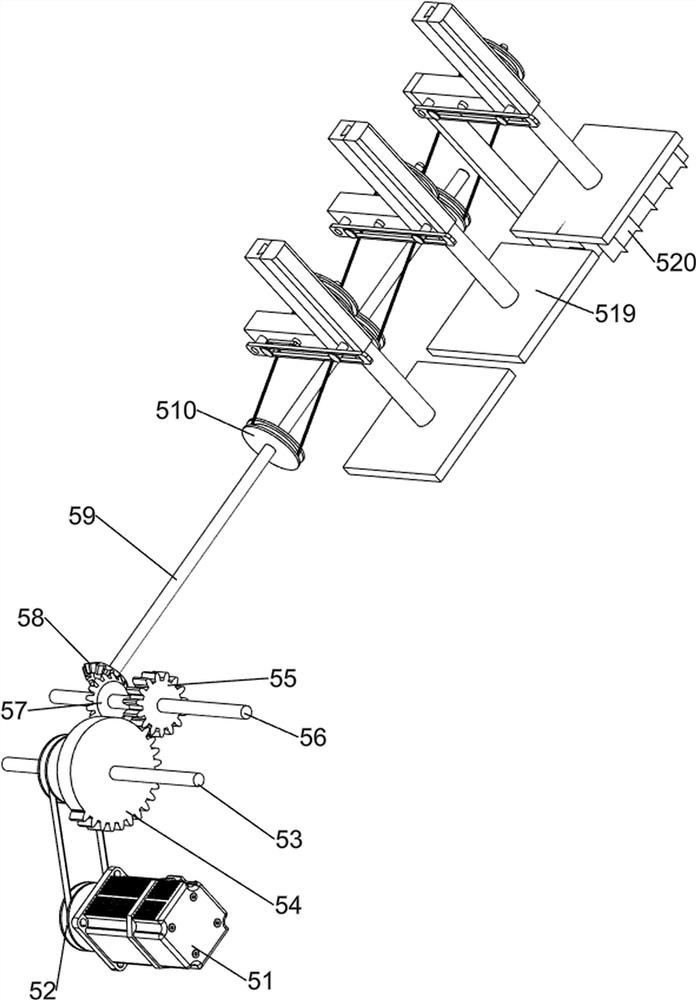

[0060] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, the circulation pressing mechanism 5 includes a motor 51, a first transmission assembly 52, a first rotating shaft 53, a missing gear 54, a first spur gear 55, a second rotating shaft 56, a first bevel gear 57, a second bevel gear 58. The third rotating shaft 59, the second transmission assembly 510, the fourth rotating shaft 511, the first connecting block 512, the first central shaft 513, the first guide rail 514, the second connecting block 515, the second guide rail 516, the limit block 517 , the first briquetting block 518, the second briquetting block 519 and the third briquetting block 520, a motor 51 is installed on the right front part of the base 1, a first transmission assembly 52 is connected to the front side of the output shaft of the motor 51, and the first support frame 2 The first rotating shaft 53 is rotationally connected with the right side of th...

Embodiment 3

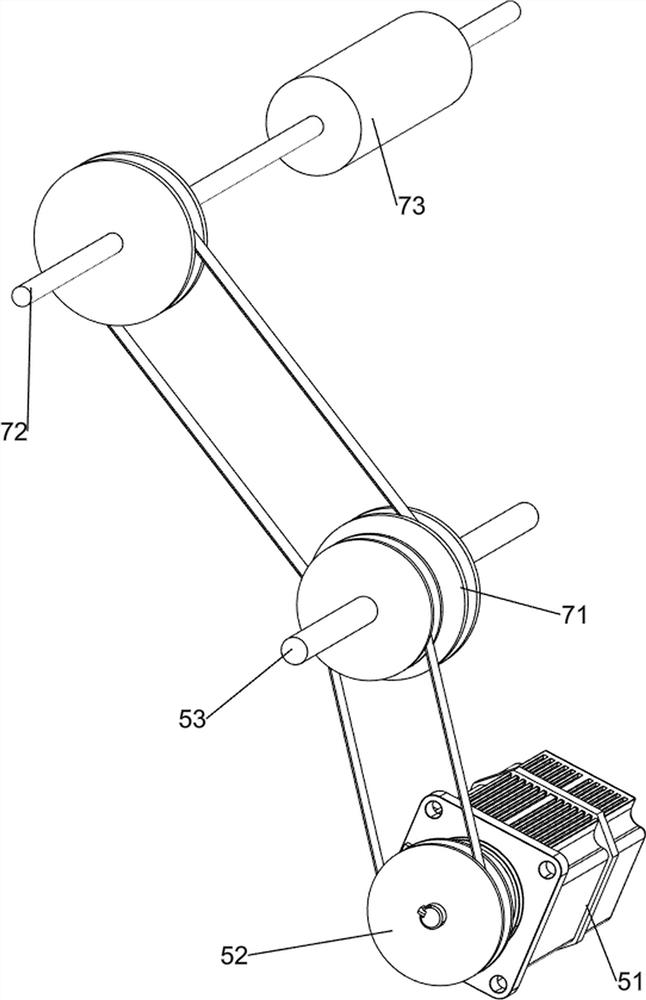

[0065] On the basis of Example 2, such as figure 1 and Figure 5 As shown, a rotating mechanism 7 is also included. The rotating mechanism 7 includes a third belt transmission assembly 71, a seventh rotating shaft 72 and a third roller 73. The third belt driving assembly 71 is arranged in the middle of the first rotating shaft 53, and the first support frame 2 The upper side and the upper side of the middle pillar 4 are rotatably connected with a seventh rotating shaft 72 , the rear side of the seventh rotating shaft 72 is provided with a third roller 73 , and the seventh rotating shaft 72 is connected with the upper side of the third belt transmission assembly 71 .

[0066] When people put the model frame filled with flour on the conveyor belt 63, the motor 51 is turned on, and the output shaft of the motor 51 rotates to drive the first transmission assembly 52 to rotate, and the rotation of the first transmission assembly 52 drives the first rotating shaft 53 to rotate, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com