Tea leaf extract as well as preparation method and application thereof

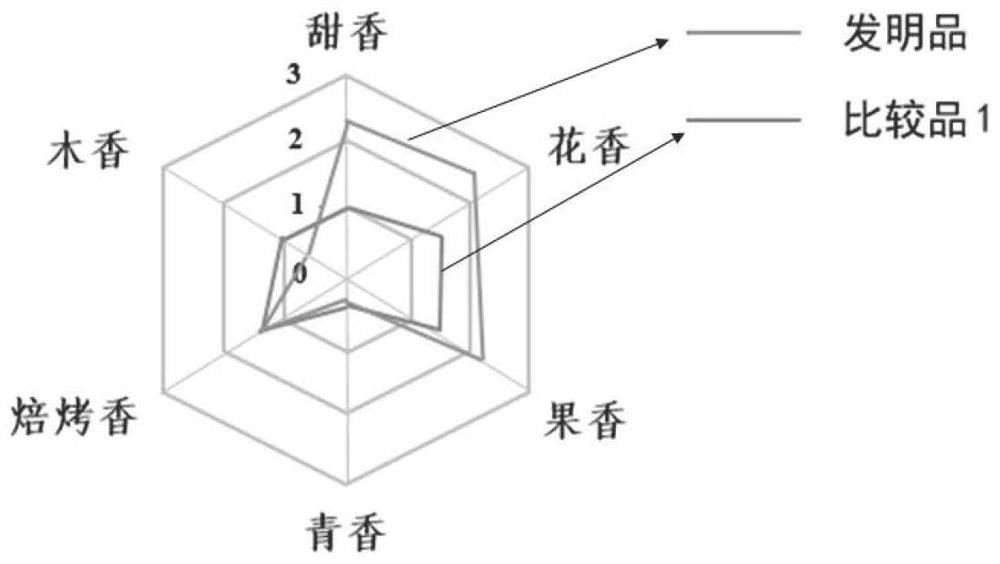

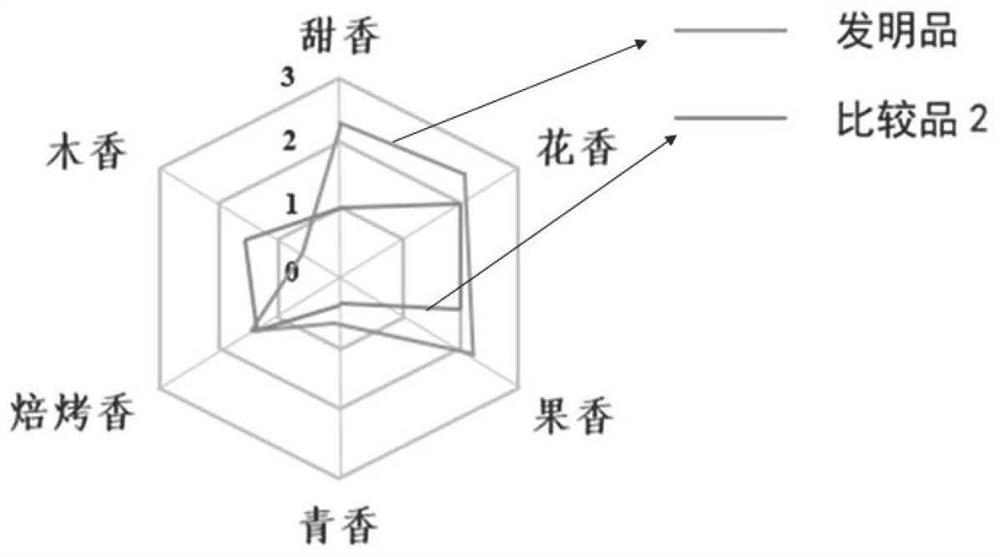

A kind of tea extract and extract technology, which is applied in the field of tea extract rich in floral aroma, tea extract and its preparation, sweet and fragrant tea extract, and fruity aroma, which can solve the problem that the long-term stability of the extract cannot be guaranteed, and the composition of the aroma poor balance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the tea extract of the present invention comprises the following steps:

[0044] (a) pulverizing the tea leaves, adding water to prepare a slurry, adding an esterification solution to obtain a tea slurry containing the esterification solution;

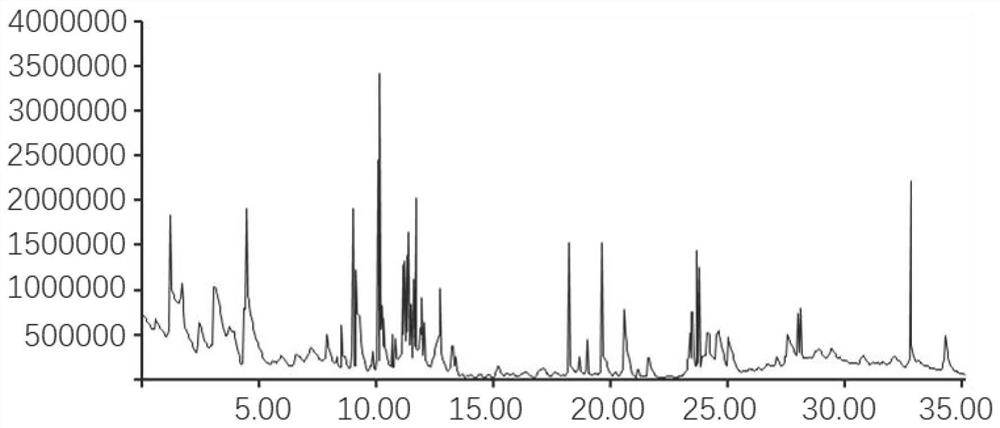

[0045] (b) performing steam-gas-liquid countercurrent distillation on the tea slurry containing esterified liquid obtained in step a, to obtain tea aroma extract 1 and a solid-liquid mixture;

[0046] (c) filtering and separating the extracted solid-liquid mixture to obtain tea soup, and concentrating the tea soup;

[0047] (d) adding an esterification solution to the concentrated tea soup, and then performing steam gas-liquid countercurrent distillation to obtain a tea aroma extract 2;

[0048] (e) Combine and mix the tea aroma extract 1 and the tea aroma extract 2 to obtain a tea extract.

[0049]In step a and / or d of the present invention, the esterification liquid is organic acids, alcohols, etc. ...

Embodiment

[0055] Preparation of esterification solution: mix yellow water, wine tail, wine head, and high-temperature Daqu powder in a mass ratio of 4:3:1:1, and seal and esterify at 32°C for 30 days. After the feed liquid after esterification was settled by centrifugation, the supernatant was taken for supercritical CO 2 Extraction, the extraction conditions are: temperature 42°C, extraction pressure 10Mpa, CO 2 The flow rate is 2400kg / h, the feed liquid flow rate is 10kg / h, the pressure of separation I is 10Mpa, the temperature of separation I is 45°C, the pressure of separation II is 8MPa, and the temperature of separation II is 35°C to obtain the esterification liquid, and the yield of the esterification liquid is 4.5%. The yellow water, wine tail and wine head come from Luzhou Laojiao Co., Ltd.

[0056] 50.0kg of raw tea leaves were pulverized and mixed with deionized water to obtain tea slurry. The mass ratio of tea to water was 1:10. Add 50g of esterification solution, mix evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com