Microwave carbonization process

A microwave and process technology, applied in the field of microwave carbonization process, can solve problems such as affecting cultivation, high cost, environmental pollution, etc., and achieve the effects of saving energy, improving efficiency, and reducing supporting facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

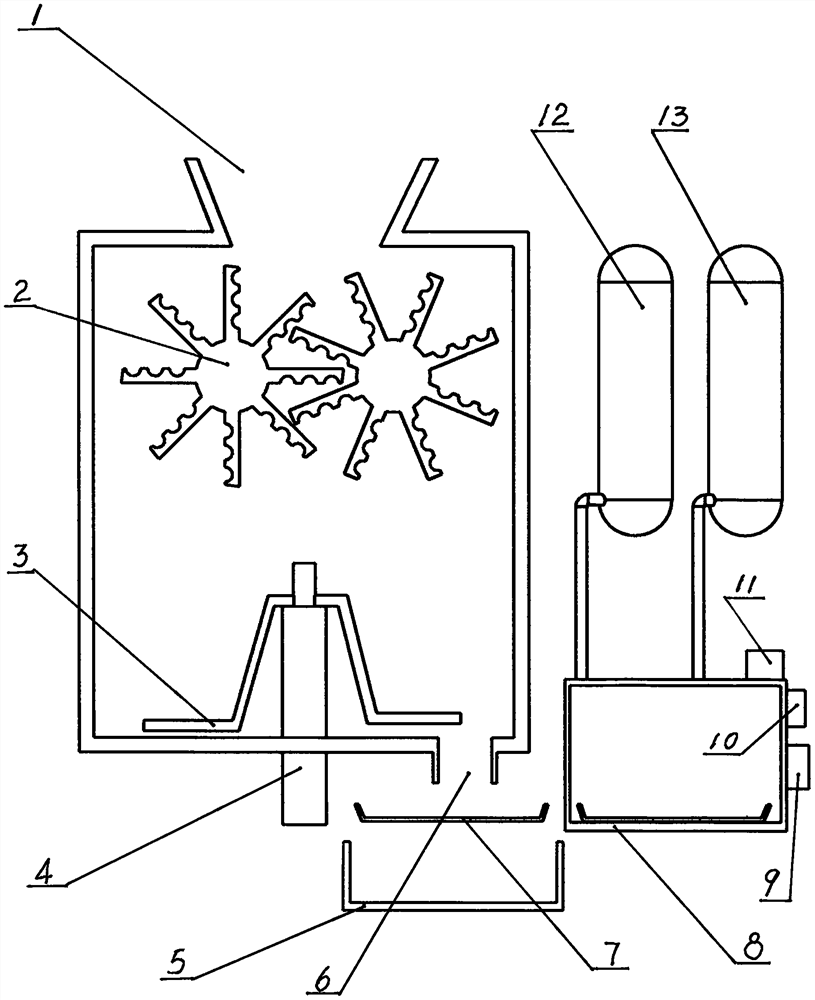

[0008] 1. From the feed port (1) through the pulverizer (2), the kitchen waste, livestock and poultry manure, and straw are pulverized into particles with a diameter of 2 cm.

[0009] 2. Add 10% water while finely pulverizing, which can be filtered sewage. The blade (3) of the fine pulverizer is composed of multiple blades. The remaining garbage, livestock and poultry manure, and straw are all crushed into paste.

[0010] 3. Finely crushed kitchen waste, livestock and poultry manure, and straw fall into the carbon fiber tray (7) through the discharge port (6). There are dense gaps at the bottom of the carbon fiber tray (7), and the gap width is 1 The millimeter acts as a wet and dry separator to filter out excess water. Lay flat in the carbon fiber tray (7), the thickness is not more than 5 cm and compacted, the pressure is 5 kg / cm2.

[0011] 4. Microwave carbonization:

[0012] a. The microwave carbonizer consists of a microwave carbonizer box (8), a transformer (9), a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com