Stamping and bending device for sheet metal machining

A punching, bending and sheet metal technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of pressure influence, low work efficiency, and physical exertion under the bending effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

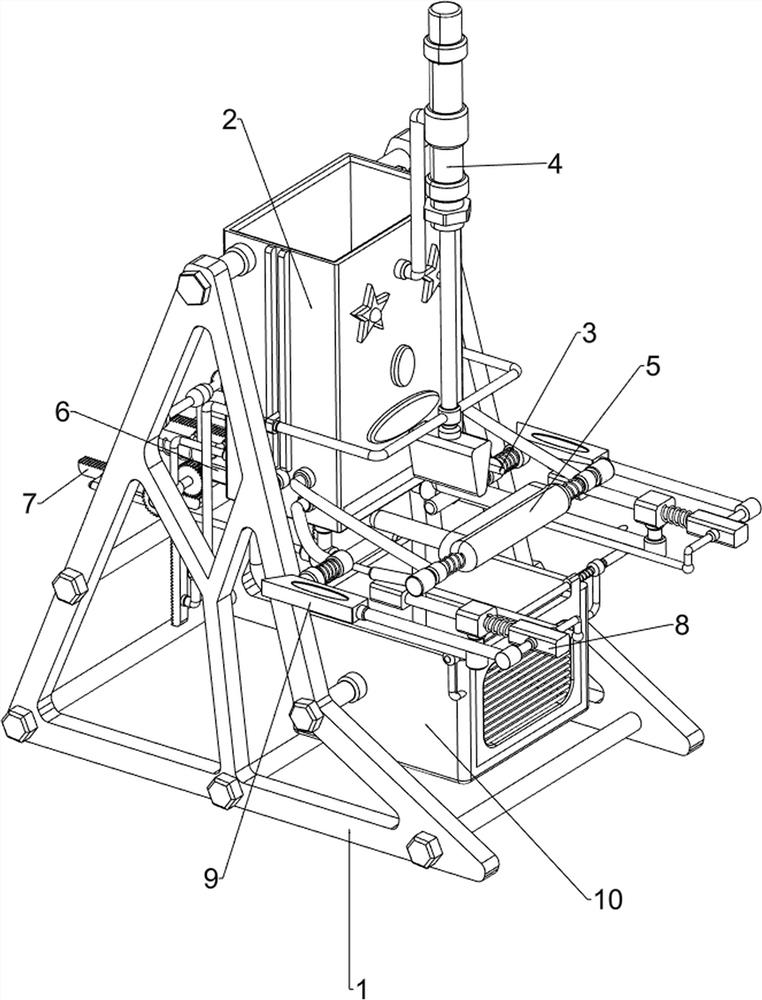

[0077] A stamping and bending device for sheet metal processing, such as figure 1 As shown, it includes a base 1, a discharge frame 2, a retaining column 3, an extrusion mechanism 4, a discharge mechanism 5 and a push mechanism 6. The upper part of the base 1 is provided with a discharge frame 2, and the right side of the lower part of the discharge frame Front and rear symmetry is provided with retaining column 3, discharge frame 2 is provided with extruding mechanism 4, discharge frame 2 is provided with discharge mechanism 5, and discharge frame 2 is provided with pusher mechanism 6.

[0078] When the sheet metal needs to be stamped and bent, the sheet metal is first put into the discharge frame 2, and then people manually pull the sheet metal onto the retaining column 3, so that the retaining column 3 blocks the sheet metal from falling, and at the same time people Rotate the discharging mechanism 5 upwards to the position that blocks the sheet metal, so that the sheet met...

Embodiment 2

[0080] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the extrusion mechanism 4 includes a support frame 41, a cylinder 42, a piston rod 43 and an extruding block 44. The right side of the upper part of the discharge frame 2 is provided with a support frame 41, and the upper part of the support frame 41 is provided with a cylinder 42. The cylinder 42 is telescopic. A piston rod 43 is arranged on the rod, and an extrusion block 44 is arranged at the bottom of the piston rod 43 .

[0081] When extruding the sheet metal, people first start the cylinder 42, and the extension of the telescopic rod of the cylinder 42 drives the piston rod 43 to move downward, and then drives the extrusion block 44 to move downward, and then performs extrusion operation on the sheet metal below, so that the sheet metal When it is bent, the telescopic rod of the cylinder 42 drives the piston rod 43 to move upward when retracting, and then drives the extrusion block 4...

Embodiment 3

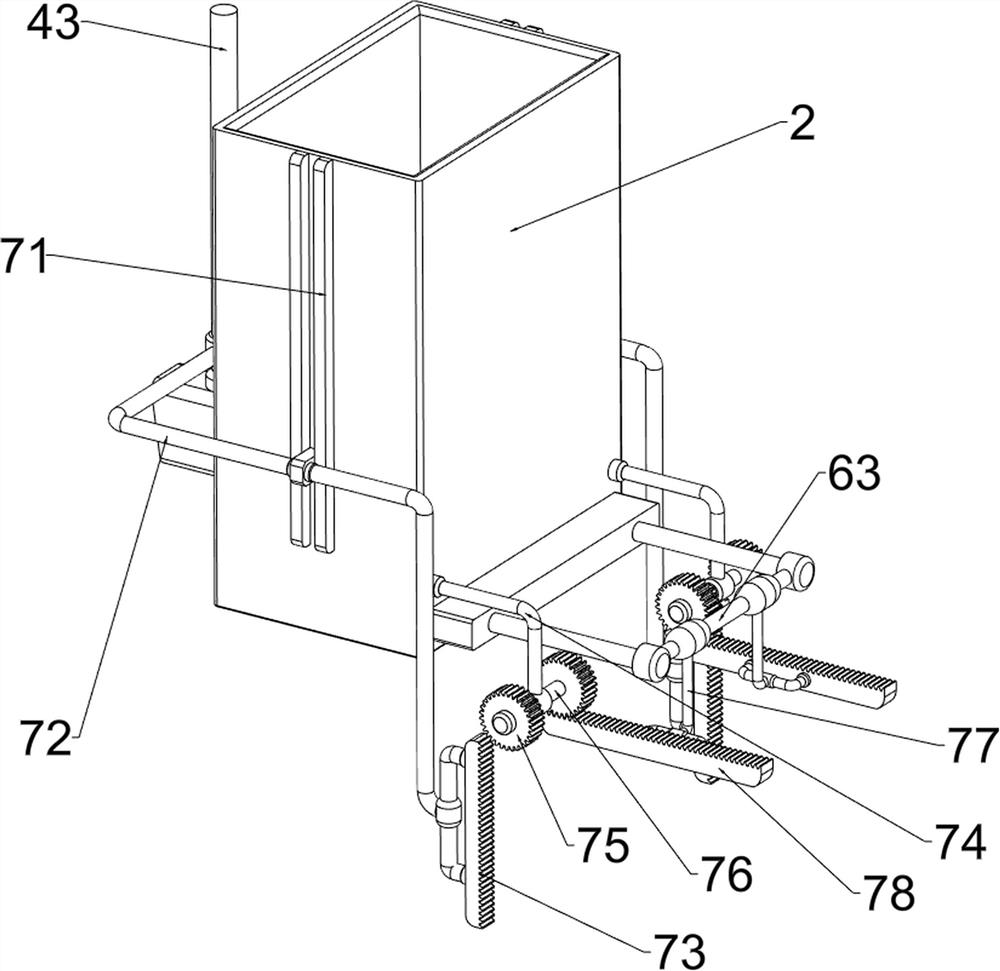

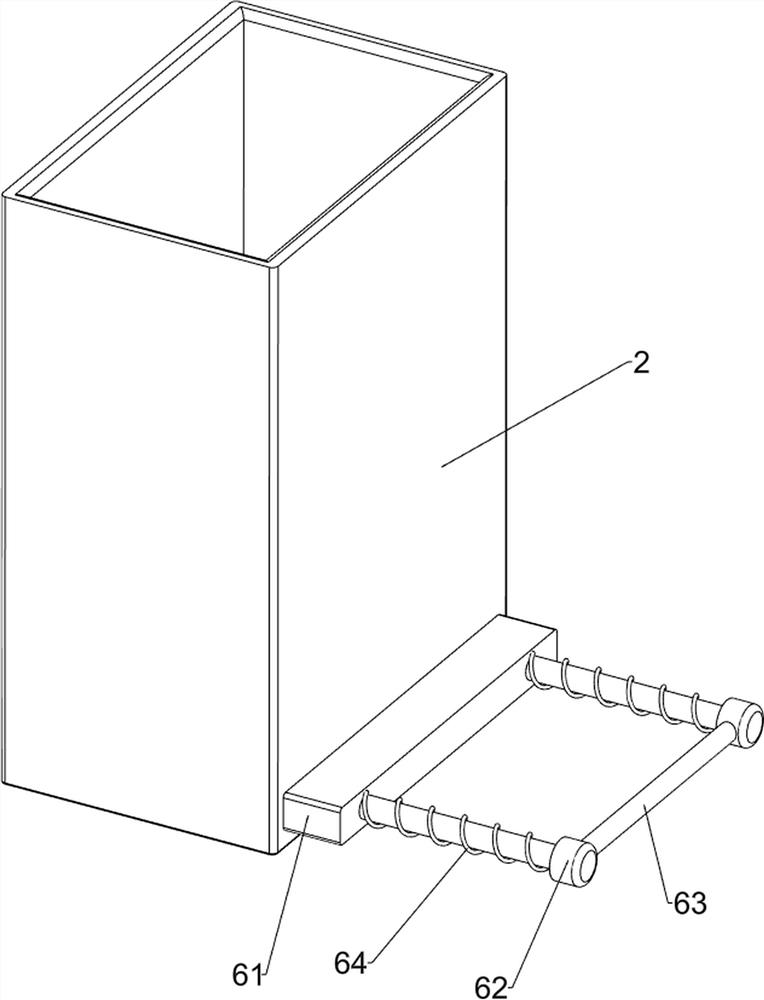

[0087] On the basis of Example 2, such as figure 1 , Figure 5 , Image 6 , Figure 7 and Figure 8 Shown, also comprise drive mechanism 7, push mechanism 8, clamping mechanism 9 and collecting mechanism 10, be provided with drive mechanism 7 on discharge frame 2, piston rod 43 and first connecting rod 63, discharge frame 2 and drive A pushing mechanism 8 is arranged on the mechanism 7 , a clamping mechanism 9 is arranged on the discharging frame 2 and the pushing mechanism 8 , and a collecting mechanism 10 is arranged on the base 1 .

[0088] In the process of bending the sheet metal, the width of the sheet metal is the longest at the beginning, just blocked by the swing rod 53, the clamping mechanism 9 clamps the swing rod 53, and the pushing mechanism 8 clamps the rotating shaft 52, realizing the automatic adjustment of the supporting sheet metal The strength makes the sheet metal more stable when it is bent. After the cylinder 42 is activated, the piston rod 43 moves u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com