Pressing module used for automatic hole manufacturing end effector

An end-effector, automatic technology, applied in manufacturing tools, metal processing mechanical parts, positioning devices, etc., can solve the problems of deformation of the workpiece to be processed, poor skin stiffness, affecting the drilling accuracy of aircraft wall panels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

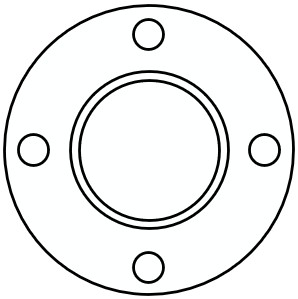

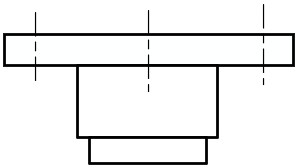

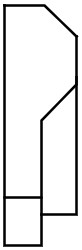

[0018]Such asfigure 1 ,figure 2 ,image 3 ,Figure 4 ,Figure 5 ,Figure 6As shown, a compression module for automatic aperture end effectors comprising a cylinder (18), a cylinder bracket (2, 3), a floating joint (17), a linear guide (4), a slider (5), Linkboard (14, 15, 16), Press Mount (9), Limited Sensor Mount (8), Limited Sensor (7), Ring Press (10), Rubber Elastic Washer (11), Laser Displacement Sensor (12), laser displacement sensor bracket (13), end effector frame (1, 6), characterized in that the cylinder brackets 1 and 2 (2, 3) are sequentially and end actuator frames from top to bottom ( 1) Connect the cylinder through the threaded connection and by the cylinder brackets 1 and 2 (2, 3) to the cylinder (18), the cylinder (18) is connected to the connecting plate 1 (16) through a floating joint (17). The linear guide (4) is connected to the end effector frame (1) by a threaded connection, the slider (5) mating with a linear guide (4), the connecting plate 1 (16), the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com