Bamboo-wood composite material coated plate and production process thereof

A composite material and production process technology, which is applied in the direction of wood processing appliances, wooden veneer joints, other plywood/plywood appliances, etc., can solve the problem of unsatisfactory structural design of painted boards, large consumption of solid wood materials, and large weather effects and other problems, to achieve the effect of good waterproof and moisture-proof effect, low cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

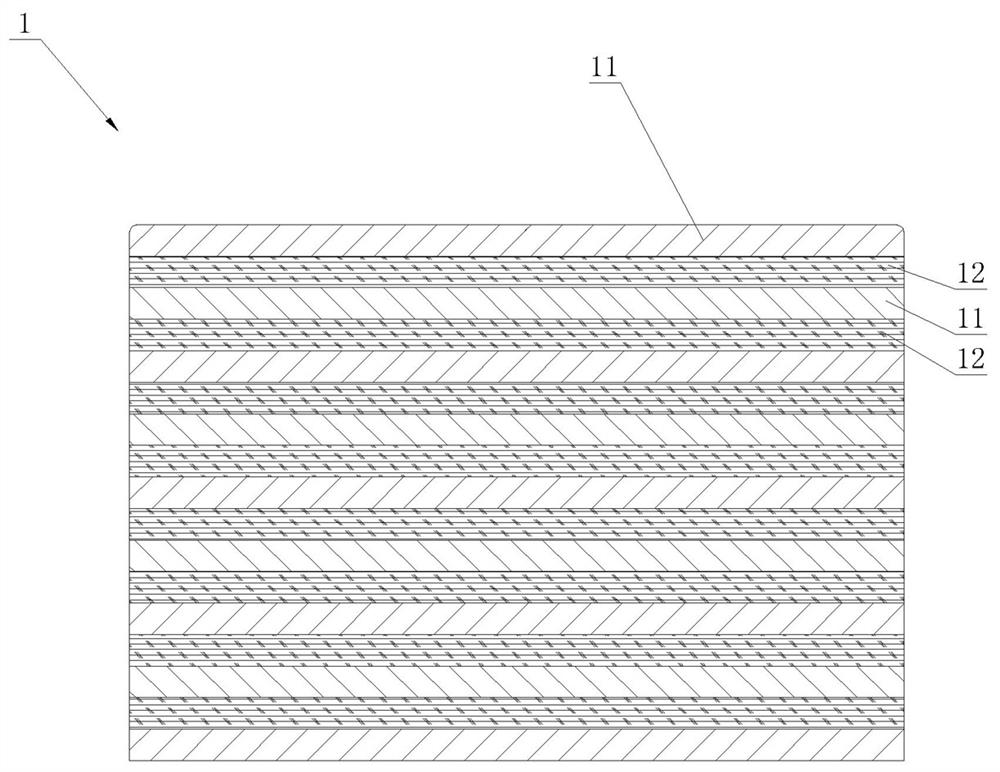

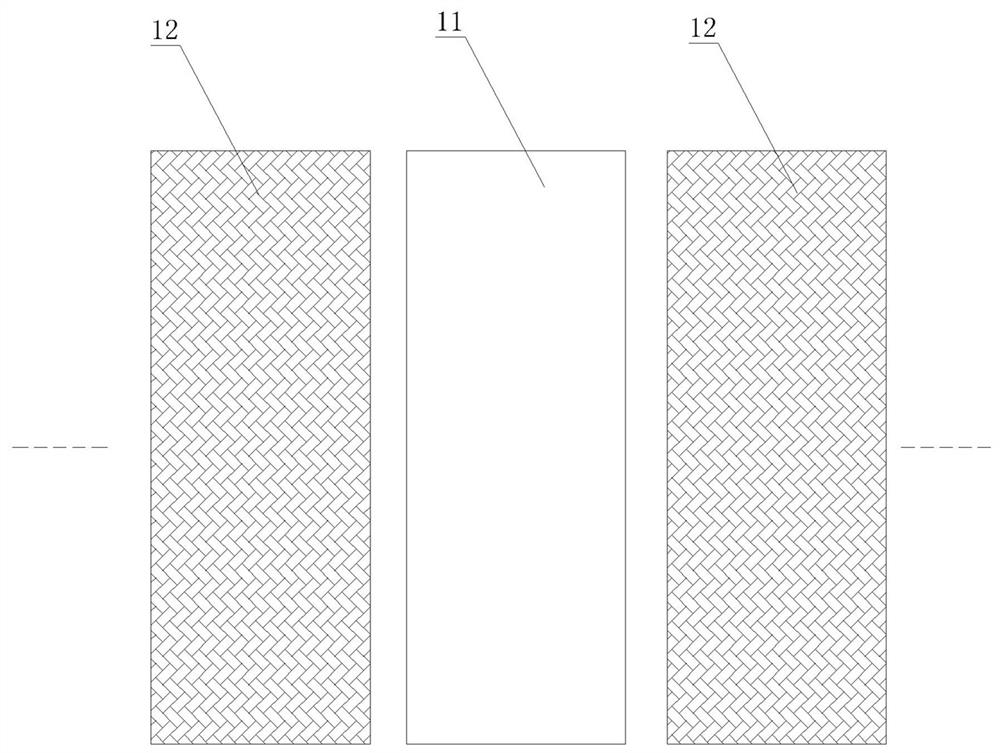

[0023] Refer to attached figure 1 and figure 2 . A kind of painted board of bamboo-wood composite material, comprises the multi-layer veneer 1 that mutually glues hot-pressed, and the texture direction of adjacent two-layer veneer is perpendicular to each other, and this multi-layer veneer 1 comprises that is made of wooden material Several wooden veneers 11 and the bamboo veneer 12 made of bamboo material are sandwiched in several wooden veneers 11, and the weight of the bamboo veneer 12 accounts for the weight of the multi-layer veneer More than 50% of the total weight of board 1 (note: generally controlled between 55% and 60%).

[0024] Refer to attached figure 1 and figure 2 . The multi-layer veneer is composed of seventeen layers of wooden veneer 11 and bamboo veneer 12 alternately laminated. Each wooden veneer 11 is a whole wooden veneer made by a rotary cutting machine. The whole wooden veneer is soaked in an anti-corrosion and flame-retardant solution and then ...

Embodiment 2

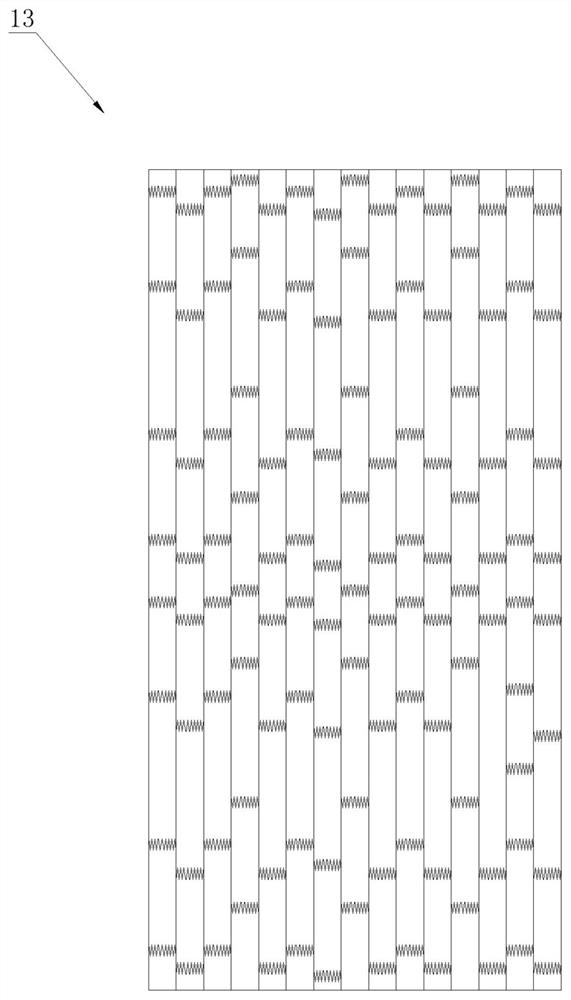

[0032] The implementation of this embodiment is basically the same as that of Embodiment 1, the difference is: refer to the attached figure 1 , Figure 5 and Figure 6 . The bamboo veneer 12 is a whole bamboo veneer made by unfolding the whole bamboo. With the design of the whole bamboo veneer, the decorative board is not easy to crack and separate, and the overall strength and deformation resistance of the painted board are greatly improved. degree. The whole bamboo veneer can be spliced horizontally by multiple whole bamboo veneers to form a large veneer; it can also be used as a small piece of veneer. Because a single whole bamboo veneer is relatively narrow, it is especially suitable for processing some bamboo and wood decorative profiles. (such as decorative lines, decorative door frame strips, door frame patios, etc.), please refer to the attached manual for details. Figure 6 . The preparation method of the whole bamboo veneer is as follows: a. Moso bamboo is cut...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap