Multi-stage membrane separation equipment

A membrane separation and equipment technology, applied in water/sewage treatment equipment, water/sewage multi-stage treatment, processing wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

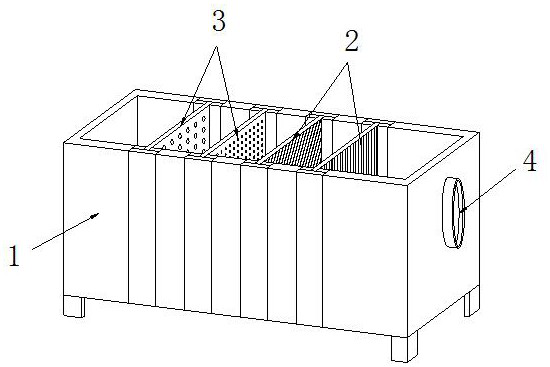

[0024] as attached figure 1 to attach Figure 5 Shown:

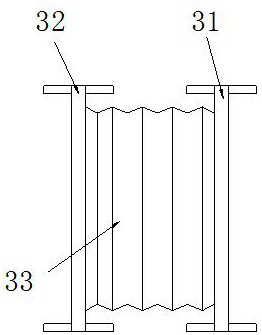

[0025] The present invention provides a multi-layer membrane separation device, the structure of which includes a box body 1, a filter membrane 2, a primary hole 3, and a drainage port 4. The inner side of the box body 1 is movably engaged with the outer side of the filter membrane 2. The outer side of the hole 3 is movably engaged with the inner side of the box body 1, and the drain outlet 4 is embedded and connected with the right end of the box body 1. The primary hole 3 includes a second filter plate 31, a first filter plate 32, and a telescopic plate 33. The outer side of the second filter plate 31 is movably engaged with the inner side of the box body 1 , the right side of the first filter plate 32 is welded to the left side of the telescopic plate 33 , and the right side of the telescopic plate 33 is welded.

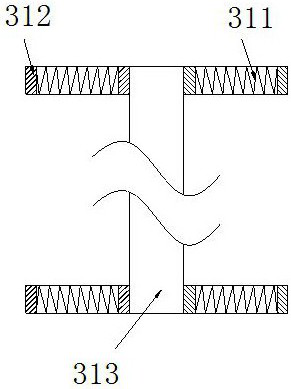

[0026] Wherein, the second filter plate 31 includes a buffer spring 311, a pad 312, and a support block...

Embodiment 2

[0032] as attached Image 6 to attach Figure 7 Shown:

[0033] Wherein, the telescopic plate 33 includes an impact plate 331, a folded layer 332, and a reset rod 333. The outer side of the impact plate 331 is welded to the outer side of the second filter plate 31, and the folded layer 332 is bolted to the outer side of the impact plate 331. The reset rod 333 is embedded and connected to the inner side of the impact plate 331. The material of the reset rod 333 is carbon spring steel, which has the characteristics of high elasticity and fatigue resistance, so that the impact plate 331 is impacted and compressed by the second filter plate 31. It can be automatically restored, and the frequency of cleaning the flocs has been improved, as stated.

[0034] Wherein, the impact plate 331 includes a fixed frame 31a, an oblique opening 31a, and a storage cavity 31c, the outer side of the fixed frame 31a is embedded and connected with the outer side of the reset rod 333, and the obliq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com