A kind of high gwit flame retardant pbt/pet alloy material and its preparation method and application

A technology of alloy materials and PBT resin, applied in the field of engineering plastics, can solve the problems that the GWIT value of flame-retardant PBT/PET alloy materials cannot reach 850°C and cannot meet the GWIT requirements, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

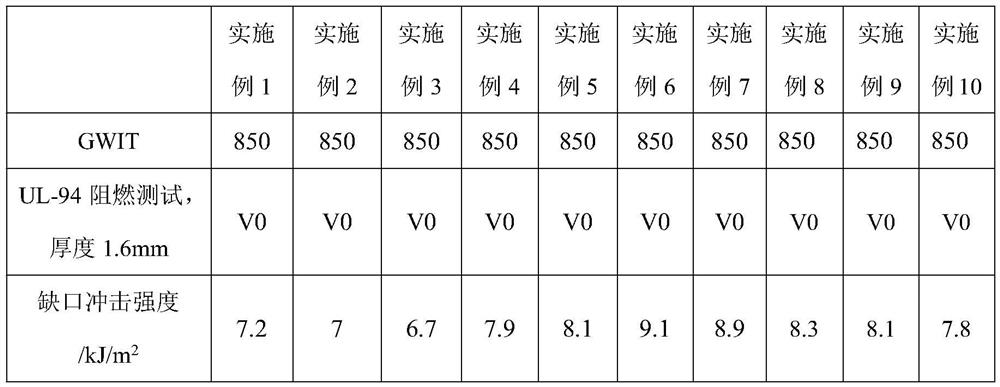

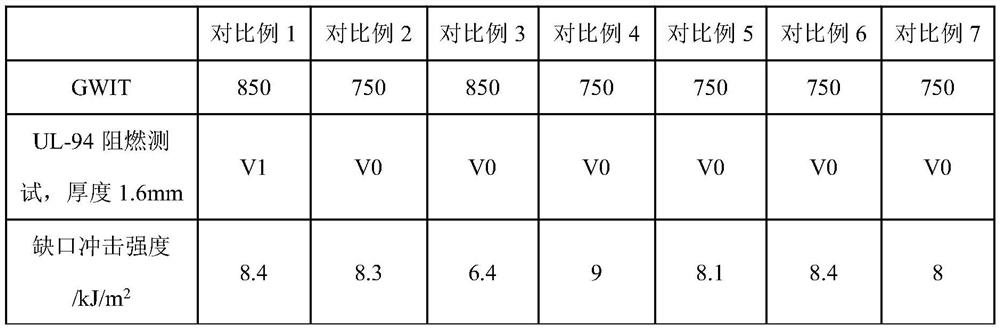

Examples

Embodiment 1~7

[0037] A high GWIT flame retardant PBT / PET alloy material, in weight percent, comprising the components shown in Table 1.

[0038] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230 ℃. Manufacturer: Changchun Chemical, Taiwan, China, brand: PBT 1200-211M

[0039] The density of PET resin is 1.31~1.33g / cm 3 , melting point 250-270 ℃. Manufacturer: Sinopec Yizheng Chemical Fiber, brand: PET FG600

[0040] The particle size of calcium hydroxide was 5 μm. Commercially available.

[0041] Brominated flame retardants are brominated epoxy resins. Manufacturer: Israel Chemical Group, brand: Powder-F-2100.

[0042] The preparation method of the high GWIT flame retardant PBT / PET alloy material is as follows:

[0043] 1) Dry the PBT at 135°C for 4 hours and set it aside for use;

[0044]2) Mix PBT resin, PET resin, brominated flame retardant, antimony trioxide and calcium hydroxide evenly, add them into the twin-screw extruder, and feed the ...

Embodiment 8

[0048] A flame-retardant PBT / PET alloy material with high GWIT, by weight percentage, comprising the following components:

[0049] 25.5 parts of PBT resin

[0050] 25 parts PET resin

[0051] 8 parts of brominated flame retardant

[0052] 0.5 parts of antimony trioxide

[0053] 4 parts calcium hydroxide

[0054] 35 parts of E-glass fiber.

[0055] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230 ℃.

[0056] The density of PET resin is 1.31~1.33g / cm 3 , melting point 250-270 ℃.

[0057] Brominated flame retardants are brominated epoxy resins.

[0058] The calcium hydroxide was calcium hydroxide with a particle size of 8 μm.

[0059] The preparation method of the flame-retardant PBT / PET alloy material with high GWIT is the same as that in Example 1.

Embodiment 9

[0061] A flame-retardant PBT / PET alloy material with high GWIT, by weight percentage, comprising the following components:

[0062] 25.5 parts of PBT resin

[0063] 25 parts PET resin

[0064] 8 parts of brominated flame retardant

[0065] 0.5 parts of antimony trioxide

[0066] 4 parts calcium hydroxide

[0067] 35 parts of E-glass fiber.

[0068] Among them, the relative density of PBT resin is 1.30-1.32g / cm 3 , melting point 215-230 ℃.

[0069] The density of PET resin is 1.31~1.33g / cm 3 , melting point 250-270 ℃.

[0070] Brominated flame retardants are brominated epoxy resins.

[0071] The calcium hydroxide was calcium hydroxide having a particle size of 10 μm.

[0072] The preparation method of the flame-retardant PBT / PET alloy material with high GWIT is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com