Spunlace compound fabric and preparation method and application thereof

A composite fabric and composite surface technology, applied in the field of sanitary products, can solve the problems of unclear mesh edges, leakage of glue on the surface layer, affecting the user experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

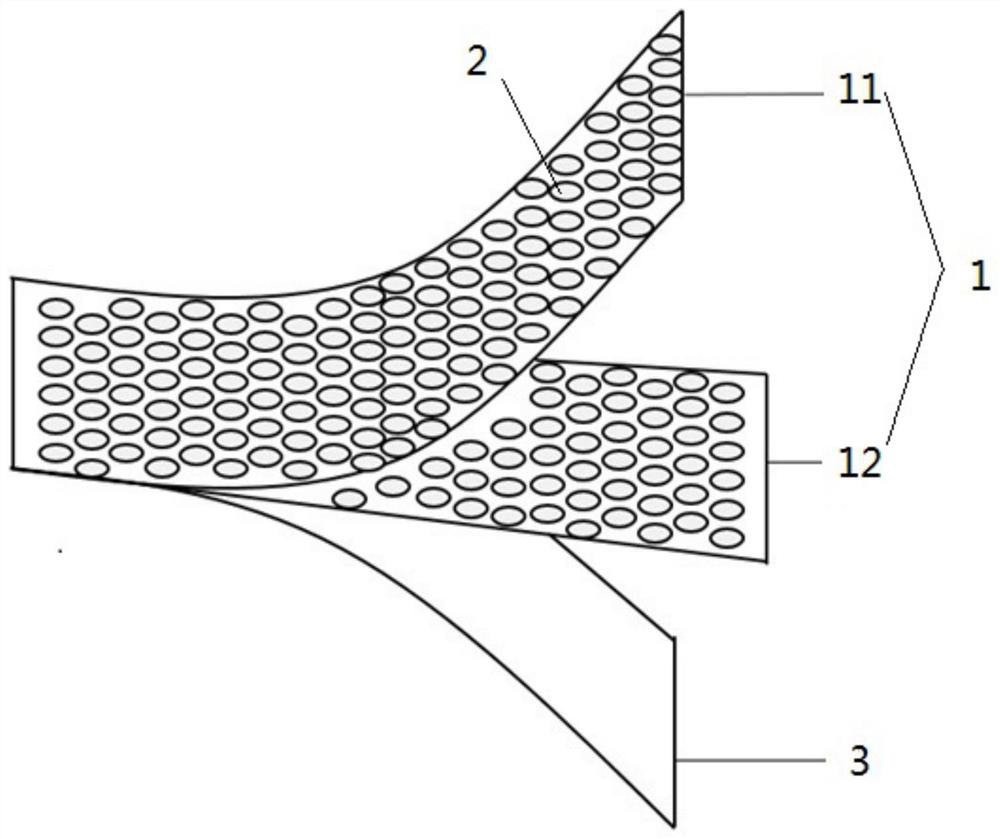

[0045] In this embodiment, the technological process for preparing spunlace composite fabrics through viscose fibers includes:

[0046] 1. Prepare materials: prepare 100% viscose fiber for use;

[0047] 2. Carding: Use a carding machine to comb the viscose fiber;

[0048] 3. Laying: The viscose fiber mesh layer is laid vertically, and the viscose fiber mesh layer is used as the surface layer;

[0049] 4. Pre-wetting: Wet the viscose fiber web layer, and use the hot-air non-woven fabric as the structural layer, and unwind the hot-air non-woven fabric prepared in advance synchronously, so that the viscose fiber web and the hot-air non-woven fabric have a preliminary combination of

[0050] 5. Spunlace: Use the high-pressure water flow of the spunlace machine to spunlace the viscose fiber web layer and the hot-air non-woven fabric on the front and back, so that the viscose fibers are entangled with each other. At the same time, the viscose fiber is also spunlace with the hot-air ...

Embodiment 2

[0060] In this embodiment, the technological process for preparing the spunlace composite fabric through 70% viscose fiber and 30% hemp fiber includes:

[0061] 1. Prepare materials: mix 70% viscose fiber and 30% hemp fiber evenly to obtain mixed fiber for use;

[0062] 2. Carding: It includes two parts: opening and carding, which is to open the mixed fiber into a single fiber state, so that it can be combed smoothly with a carding machine;

[0063] 3. Laying: use vertical laying to lay the mixed fiber mesh layer;

[0064] 4. Pre-wetting: Wet the mixed fiber web layer, and use the hot air non-woven fabric as the structural layer, and unwind the hot air non-woven fabric prepared in advance synchronously, so that the mixed fiber web layer and the hot air non-woven fabric have a preliminary Combine;

[0065] 5. Spunlace: Use the high-pressure water flow of the spunlace machine to spunlace the mixed fiber web layer and the hot-air non-woven fabric on the front and back, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com