Method for generating drilling point demonstration by point drilling machine according to track

A trajectory generation and teaching technology, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of time-consuming, time-consuming and labor-intensive teaching, improve production efficiency and product quality, reduce Teaching time, simple and quick operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0050] In the process of dispensing and dispensing drilling, the dot drilling machine is preset with a fixed coordinate system to facilitate the positioning of the dispensing head, dot drill and workpiece. The uppermost corner of the image field of view is taken as the origin, and the directions of X and Y follow the plane right angle. In the coordinate system, the orientation right and down are the positive directions of X and Y respectively, and Z is the direction perpendicular to the plane.

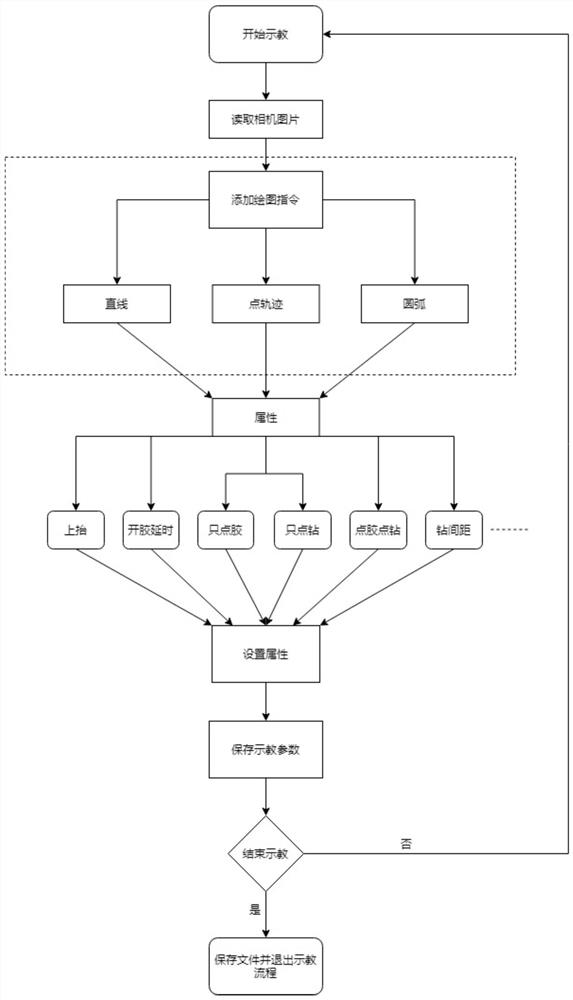

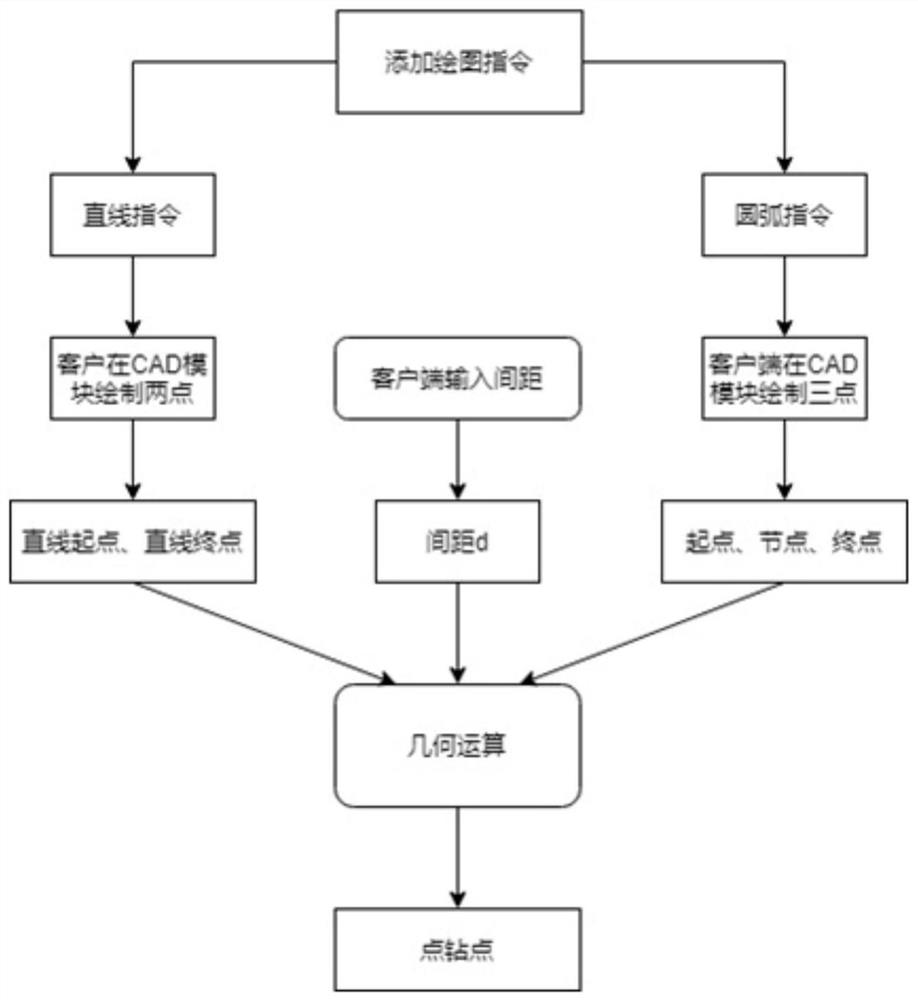

[0051] The invention relates to a method for point drilling machine to generate drilling point teaching according to trajectory, such as Figure 1-2 shown, including the following steps:

[0052] Step 1, create a curve drawing instruction (the curve includes a straight line and an arc) in the CAD module of the spot drilling software.

[0053] Step 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com