Light injection passivation method of Topcon cell

A light injection and battery technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as unstable efficiency improvement, achieve the effect of improving surface passivation and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

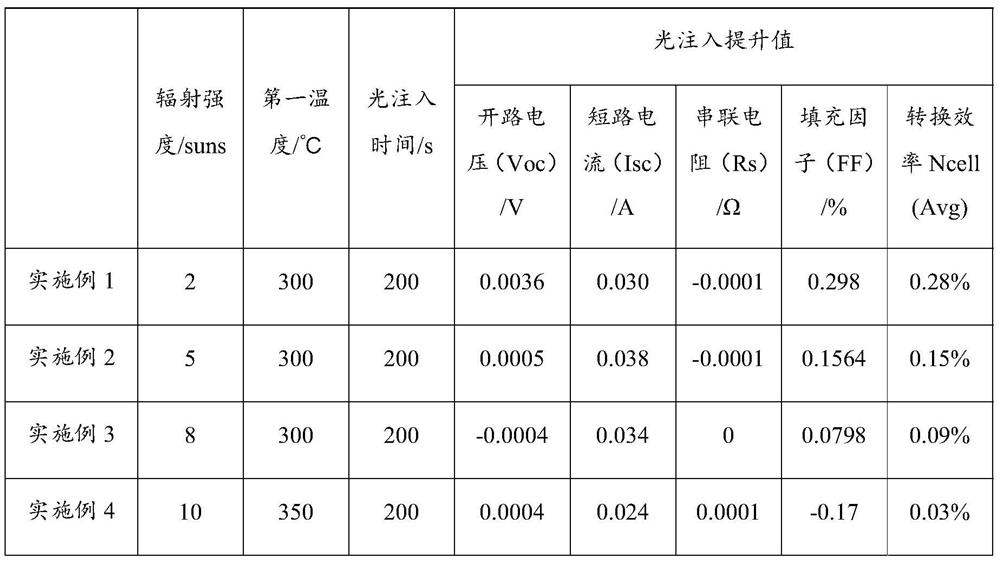

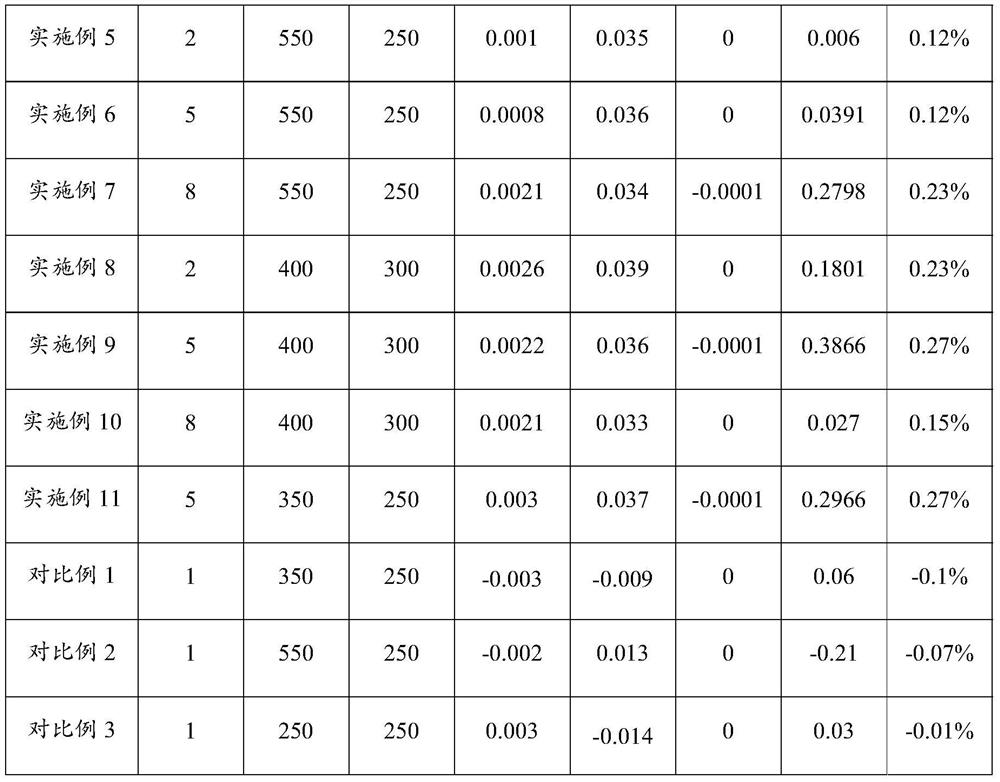

Embodiment 1

[0034] This embodiment provides a light injection passivation method for a Topcon battery, which includes:

[0035]Put the metallized Topcon cells one by one along the transmission direction into the chain conveyor belt for transmission. During the transmission process, the metallized Topcon cells are injected with light and supplemented by heating to achieve passivation. The radiation intensity of the light injection is 2suns, the light injection time is 200s.

[0036] Among them, the heating process includes a heating stage, a cooling stage and a heat preservation stage. The heating stage includes heating the Topcon battery to a surface temperature of 300°C in 50s, and the cooling stage includes reducing the surface temperature of the Topcon battery from 300°C to 300°C in 84s. 200°C, in the heat preservation stage, the Topcon battery is held at a temperature of 200°C for 66s.

Embodiment 2

[0038] This embodiment provides a light injection passivation method for a Topcon battery, which includes:

[0039] Put the metallized Topcon cells one by one along the transmission direction into the chain conveyor belt for transmission. During the transmission process, the metallized Topcon cells are injected with light and supplemented by heating to achieve passivation. The radiation intensity of the light injection is 5suns, the light injection time is 200s.

[0040] Among them, the heating process includes a heating stage, a cooling stage and a heat preservation stage. The heating stage includes heating the Topcon battery to a surface temperature of 300°C in 50s, and the cooling stage includes reducing the surface temperature of the Topcon battery from 300°C to 300°C in 84s. 200°C, in the heat preservation stage, the Topcon battery is held at a temperature of 200°C for 66s.

Embodiment 3

[0042] This embodiment provides a light injection passivation method for a Topcon battery, which includes:

[0043] Put the metallized Topcon cells one by one along the transmission direction into the chain conveyor belt for transmission. During the transmission process, the metallized Topcon cells are injected with light and supplemented by heating to achieve passivation. The radiation intensity of the light injection is 8suns, the light injection time is 200s.

[0044] Among them, the heating process includes a heating stage, a cooling stage and a heat preservation stage. The heating stage includes heating the Topcon battery to a surface temperature of 300°C in 50s, and the cooling stage includes reducing the surface temperature of the Topcon battery from 300°C to 300°C in 84s. 200°C, in the heat preservation stage, the Topcon battery is held at a temperature of 200°C for 66s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com