Feed crushing device for livestock breeding

A crushing device and feed technology, applied in feed, application, grain processing, etc., can solve problems such as difficult collection, hand damage, body injury, etc., and achieve the effects of improving work efficiency, facilitating collection, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

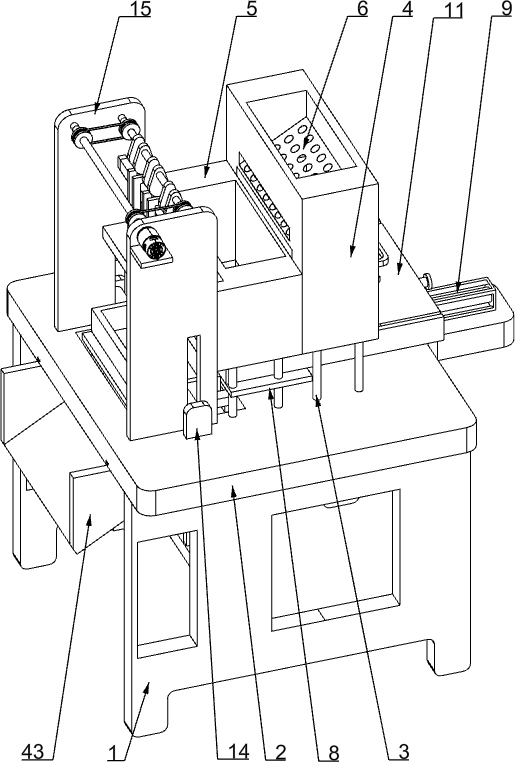

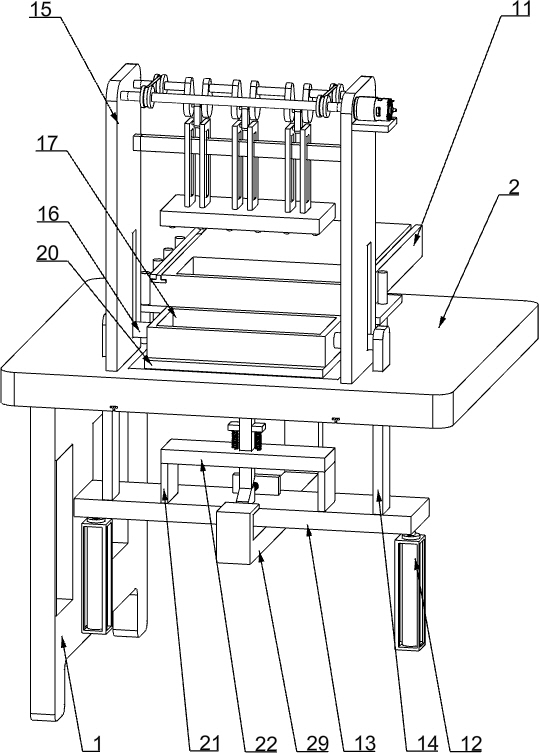

[0030] A feed crushing device for livestock breeding, such as figure 1 As shown, it includes a support leg 1, a bottom plate 2, a material distribution mechanism, a feeding mechanism, a lifting mechanism, a discharge mechanism and a crushing mechanism. There are two support legs 1, and the bottom plate 2 is fixedly installed on the top of the two support legs 1. The feeding mechanism is installed in the middle of the upper side of the bottom plate 2, the feeding mechanism is installed on the upper side of the bottom plate 2, the feeding mechanism is between the bottom plate 2 and the distribution mechanism, and the upper side of the feeding mechanism is slidingly connected with the lower side of the distribution mechanism. There is a long hole on the bottom plate 2, and a part of the feeding mechanism is slidingly connected with the long hole on the bottom plate 2. There is also a rectangular hole on the bottom plate 2. The lifting mechanism is installed on both sides of the bo...

Embodiment 2

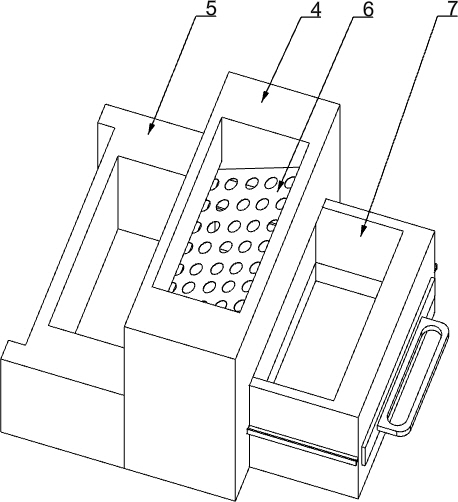

[0033] On the basis of Example 1, such as Figure 2-9As shown, the material distribution mechanism includes a pillar 3, a material distribution box 4, a material receiving box 5, a screening plate 6 and a material receiving box 7, and there are eight pillars 3, of which four pillars 3 are on the front side above the bottom plate 2, and in addition The four pillars 3 are on the rear side above the base plate 2, and the material distribution box 4 is fixedly installed on the four pillars 3 tops on the right side, and the receiving box 5 is fixedly installed on the four pillars 3 tops on the left side, and the left side of the material distribution box 4 has a Rectangular opening, the screening plate 6 is obliquely installed inside the material distribution box 4, the left end of the screening plate 6 is fixedly connected with the lower side of the rectangular opening on the material distribution box 4, and the other right side of the material distribution box 4 also has a rectang...

Embodiment 3

[0044] On the basis of Example 2, such as figure 1 with Figure 9 Shown, also include spheroid 40, and spheroid 40 has a plurality of, and a plurality of spheroid 40 is fixedly installed on the underside of pressing plate 39, and when smashing downwards, spheroid 40 can make feed smashed more broken.

[0045] A plurality of spheroids 40 are fixedly installed on one side of the pressing plate 39, and the spheroids 40 are installed on one side of the pressing plate 39, so that one side of the pressing plate 39 becomes uneven, and when smashing downwards, the spheroids 40 can make the feed smashed more broken.

[0046] A slideway 43 is also included, and the slideway 43 is fixedly installed on the lower side of the bottom plate 2 , and the right end of the slideway 43 corresponds to the left end of the rotating plate 20 .

[0047] When the smashed feed slides down from the rotating plate 20, it will fall on the slideway 43, and the slideway 43 plays a guiding role, and the smash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com