Vacuum brazing method suitable for closed cavity multi-welding-seam structure

A brazing method and closed cavity technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex weld structure, uneven weld gap, and inability to fill in brazing material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

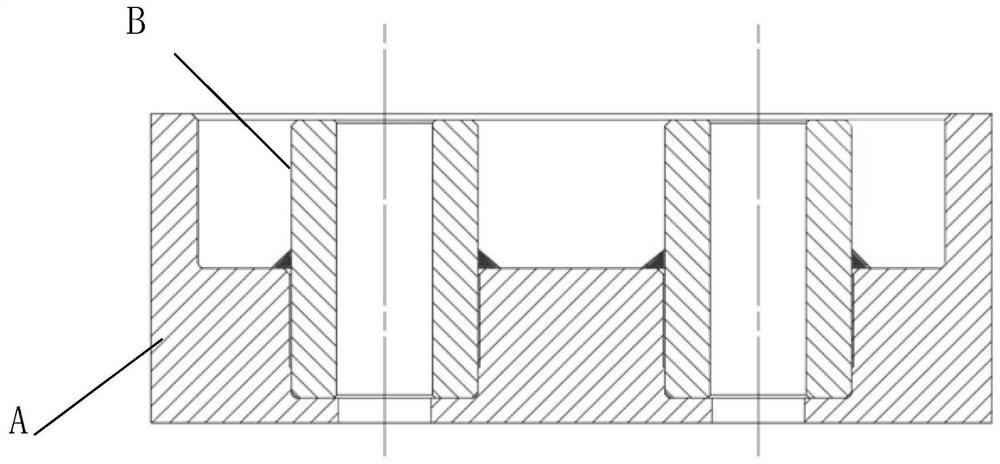

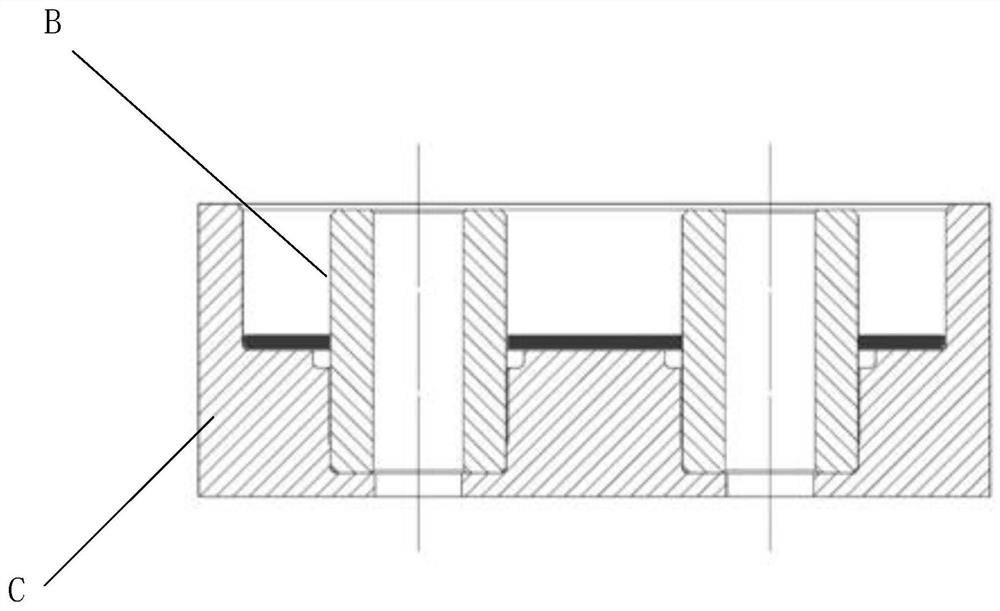

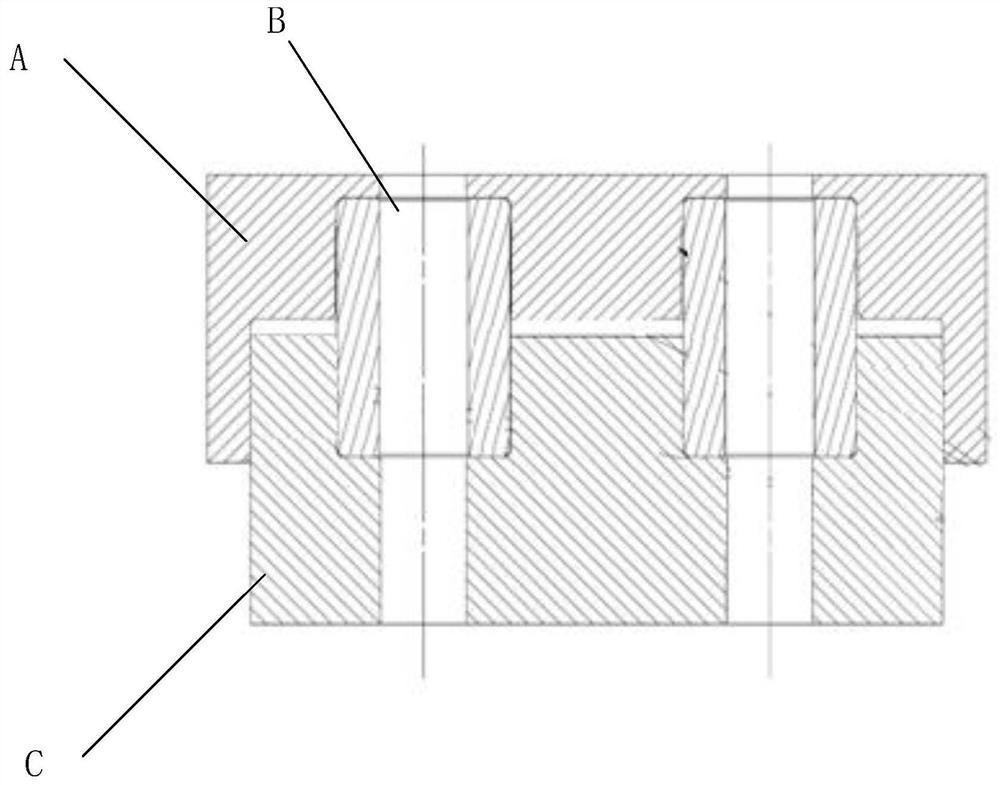

[0057] Such as Figures 1 to 3 as shown,

[0058] A vacuum brazing method suitable for a closed cavity multi-weld structure, comprising the following steps:

[0059] 1) Control the weld length of part A and part B to be greater than or equal to 3.5mm;

[0060] 2) Control the gap d1 in the upper part of the weld between part A and part B = 30-80 μm, and the gap d2 in the lower part = 5-10 μm, where the length L of the weld in the lower part is 0.5-1.5 mm;

[0061] 3) Put parts A and B in alcohol or acetone, use ultrasonic cleaning for 10±5min, and dry parts A and B with a blower;

[0062] 4) Coating the paste solder through a syringe, and measuring the weight change of solder before and after coating with an electronic scale, recording the amount of solder coated, and controlling the amount of solder to be 0.06-0.1g;

[0063] 5) Use a drying oven to dry at a temperature of 100±20°C for 1h±30min;

[0064] 6) The parts are placed on the material tray of the brazing furnace, a...

Embodiment 1

[0076] Aiming at parts A, B and C made of 0Cr18Ni9 stainless steel, a vacuum brazing method suitable for a closed cavity multi-weld structure comprises the following steps:

[0077] 1) Control the weld length of part A and part B to be 3.5mm;

[0078] 2) Control the upper part of the weld gap between part A and part B to be d1 = 30 μm, and the lower part gap d2 = 5 μm, where the length of the weld in the lower part is L = 0.6 mm;

[0079] 3) Put parts A and B in alcohol or acetone, ultrasonically clean them for 10 minutes, and dry them with a blower;

[0080] 4) Evenly coat the BNi-2 paste solder through a syringe, and use an electronic scale to weigh the weight change of the solder before and after coating, record the amount of solder coated, and control the amount of solder to 0.06g;

[0081] 5) Use a drying oven to dry for 80 minutes at a temperature of 110°C;

[0082] 6) The parts are placed on the material tray of the brazing furnace, and the parts cannot be touched. Th...

Embodiment 2

[0088] Such as Figure 4 As shown, for parts A, B and C of Inconel 625 superalloy material, a vacuum brazing method suitable for closed cavity multi-weld structure, the operation steps are as follows;

[0089] 1) Control the weld length of part A and part B to be 4mm;

[0090] 2) Control the upper part of the weld gap between part A and part B to be d1=50μm, and the lower part gap d2=8μm, where the length of the lower part of the weld is L=1mm;

[0091] 3) Put parts A and B in alcohol or acetone, ultrasonically clean them for 15 minutes, and dry them with a blower;

[0092] 4) Apply the BCo-1 paste solder evenly through the syringe, and use an electronic scale to weigh the weight change of the solder before and after coating, record the amount of solder coated, and control the amount of solder to 0.1g;

[0093] 5) Use a drying oven to dry for 90 minutes at a temperature of 120°C;

[0094] 6) The parts are placed on the material tray of the brazing furnace, and the parts can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com