Rapid drying device for printing ink on paper surface

A surface printing and fast drying technology, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., to achieve the effect of improving drying efficiency, ensuring drying efficiency, and increasing transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

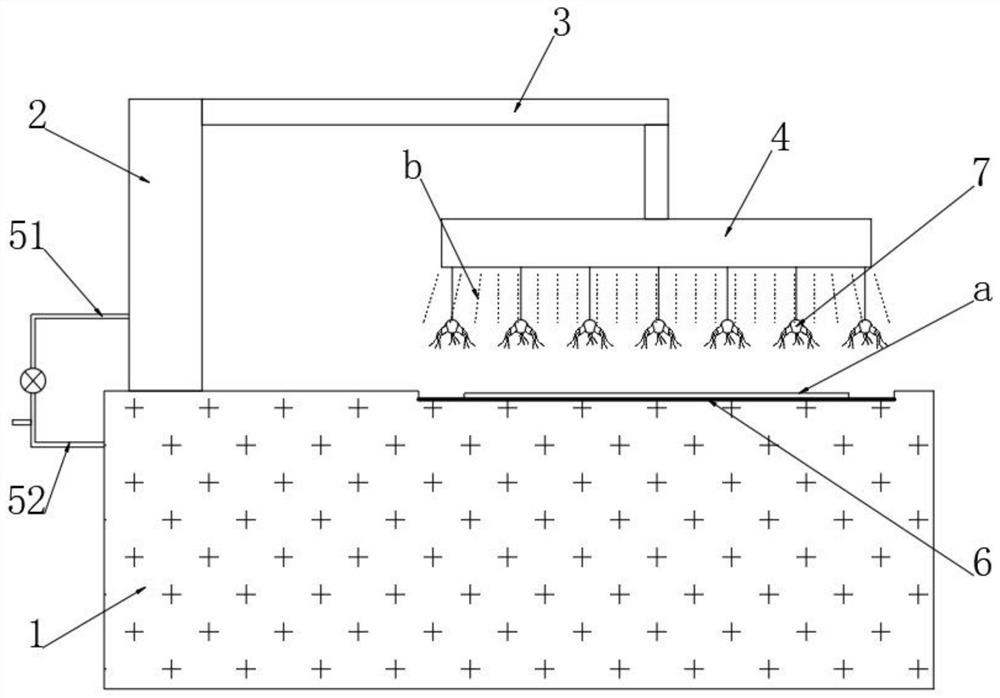

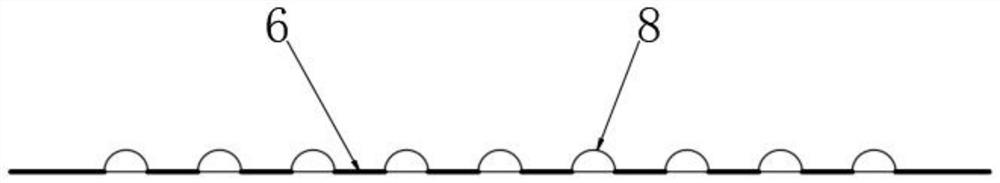

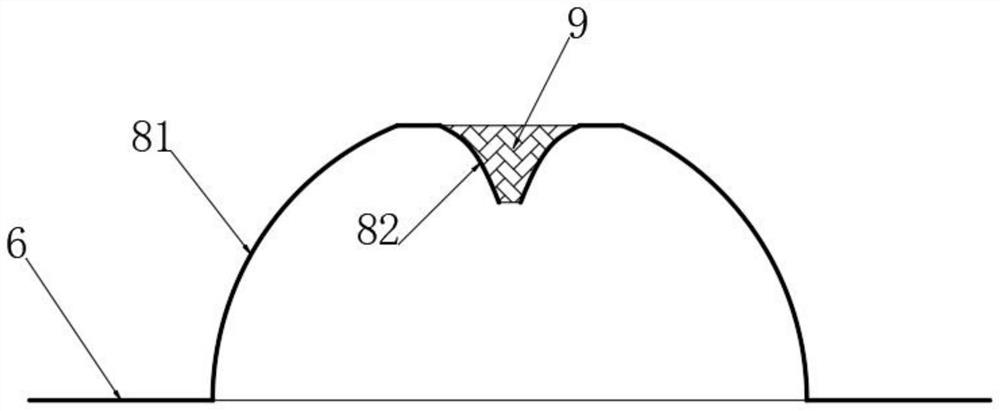

[0043] see figure 1 , a paper surface printing ink rapid drying device, including a device body 1, a conveyor belt assembly is installed on the upper right end of the device body 1, a support vertical pipe 2 is fixedly connected to the upper left end of the device body 1, and a support horizontal pipe is fixedly connected to the right end of the support vertical pipe 2 The tube 3 and the lower end of the supporting horizontal tube 3 are fixedly connected with a porous drying head 4. The porous drying head 4 is located directly above the conveyor belt 6 in the conveyor belt assembly. The device body 1 is provided with an external circulation system. The external circulation system includes an exhaust fan, The double-head suction pipe 52 fixedly connected to the air inlet of the exhaust fan and the air inlet pipe 51 fixedly connected to the air outlet of the exhaust fan, the end of the air inlet pipe 51 away from the exhaust fan is fixedly connected to and communicated with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com