Belt type filter pressing device for sludge and working method thereof

A sludge belt type, sludge technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Difficulty in meeting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

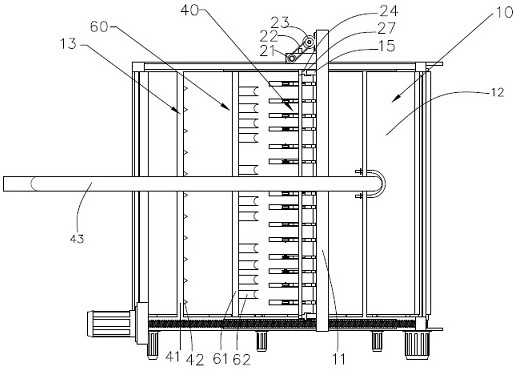

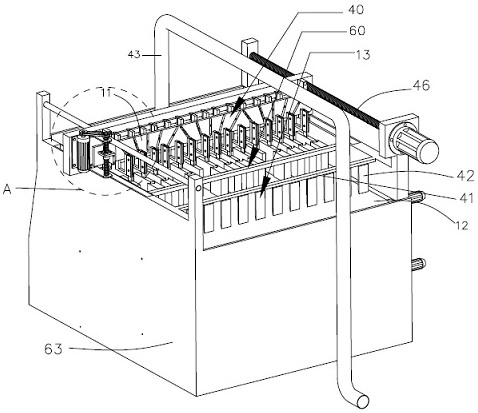

[0035] Such as Figure 1 to Figure 7 As shown, a sludge belt filter press device provided by the present invention includes a flocculation zone, a sludge gravity settling zone 10 and a sludge squeezing squeeze zone 40 connected in sequence.

[0036] The sludge gravity settling area 10 is provided with a pre-press assembly 11 , a filter cloth 12 and a scraper assembly 13 , and the pre-press assembly 11 is arranged above the filter cloth 12 .

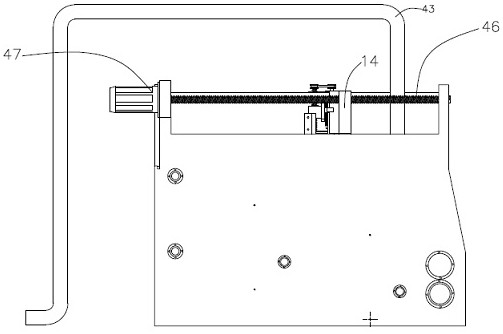

[0037] in, Figure 8 with Figure 9Among them, the preloading assembly 11 includes a base plate 14, a vertical guide slide 15, a horizontal guide slide 16, a driven plate 17, a driving plate 18, a clamping plate 19, a horizontal moving body 20, a lifting screw 21, a conveyor belt 22 and a drive motor 23, the driving motor 23 is arranged on the base plate 14, the driving motor 23, the conveyor belt 22 and the lifting screw 21 are connected in sequence, the driven plate 17 is set on the lifting screw 21, the driven plate 17 is fixedly con...

no. 2 example

[0045] One end of the substrate 14 in this embodiment is sleeved on the horizontal screw rod 46, the horizontal screw rod 46 is connected with the horizontal motor 47, the other end of the substrate 14 is slidably arranged on the horizontal sliding rod 48, and the lower end of the substrate 14 is slidable by rollers The mud scraping assembly 60 is arranged on the downstream side of the preloading assembly 11, and the mud scraping assembly 60 has a blocking rod 61 and a mud scraping blade 62, and the two ends of the blocking rod 61 are fixed On the frame wall 63, and the mud scraper 62 is arranged on the traveling direction of the clamping area of two adjacent clamping plates 19;

[0046] The working method includes the following steps:

[0047] The horizontal motor 47 drives the horizontal screw 46 to work, and the horizontal screw 46 correspondingly drives the substrate 14 to move axially along the horizontal screw 47 and the horizontal sliding rod 48. Correspondingly, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap