Full-band super-structure sound absorber

A sound-absorbing body and full-band technology, which is applied to building components, building structures, and sound insulation, can solve the problems of high structural density and general low-frequency sound absorption performance, and achieve good sound absorption performance, compact structure, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

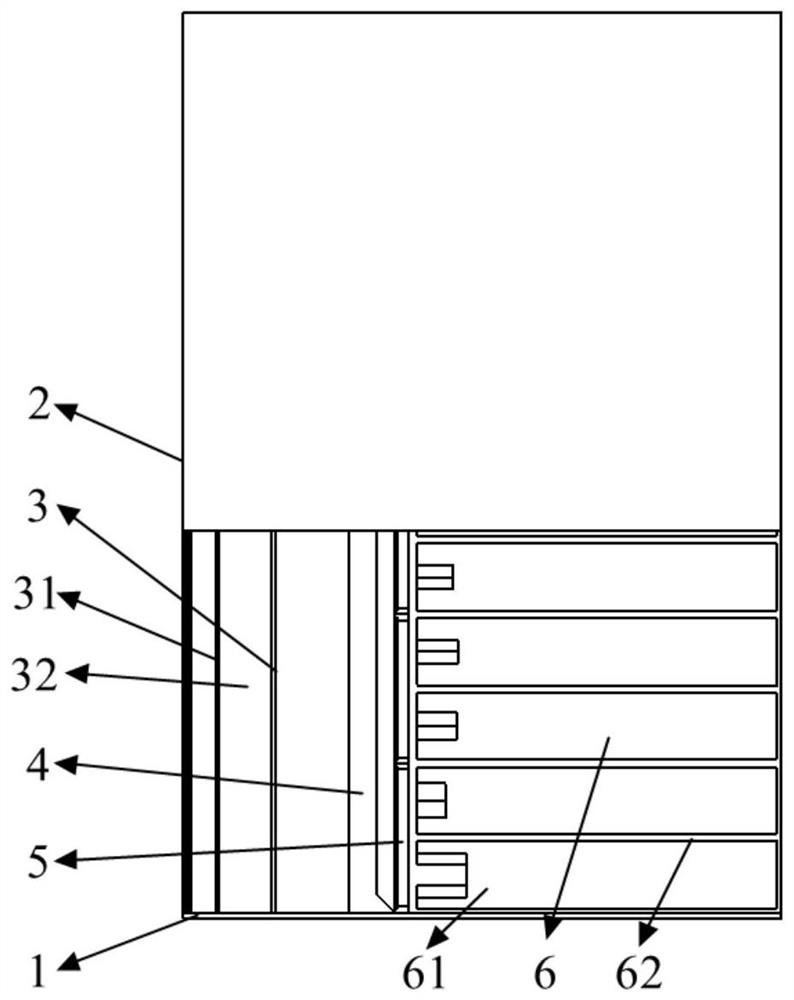

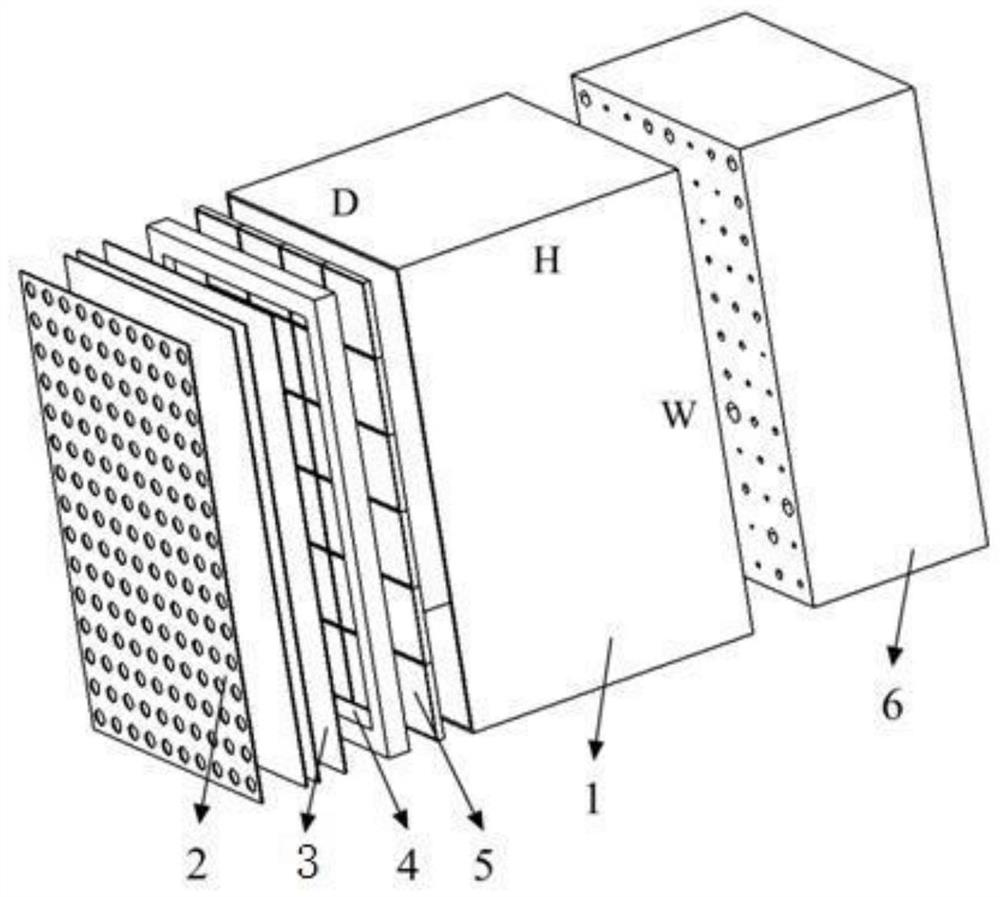

[0022] Such as figure 1 The full-band superstructure sound-absorbing body shown includes a frame body 1, a front panel 2, a high-frequency sound-absorbing body 3, an intermediate-frequency resonant cavity 4, an impedance matching layer 5, and a low-frequency sound-absorbing body 6, and the front panel 2 and each absorbing body The sound body is fixed on the frame body 1 through a slot and a buckle. Superstructure sound absorbing body, its external dimensions are: 300mm (W) × 200mm (D) × 235mm (H).

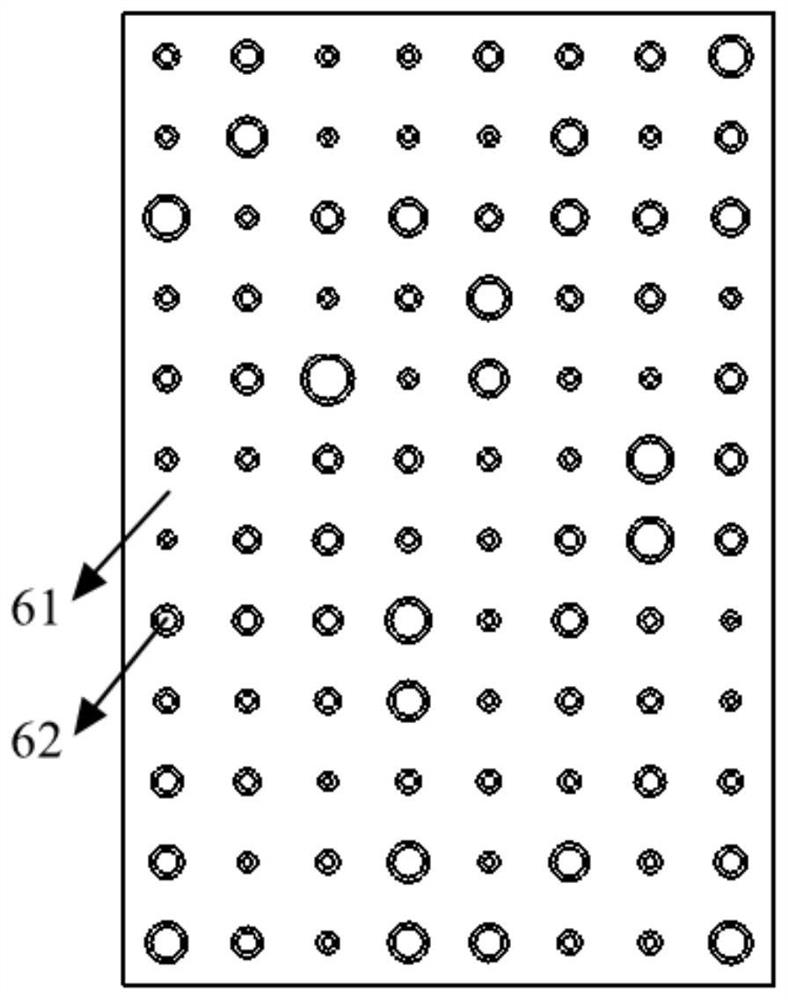

[0023] see Figure 2-4 , the front panel 2 is a metal perforated plate with a thickness of 1 mm, a perforation diameter of 5.0 mm, and a perforation rate of 45%. The high-frequency sound absorbing body 3 is a sound-absorbing structure in which four layers of micro-perforated plates 31 are arranged in series. Each micro-perforated plate 31 is separated by a back cavity 32....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Taper | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com