Novel combustion box of wood particle furnace

A technology of burning box and wood pellets, which can be used in household stoves/stoves, solid heating fuels, climate sustainability, etc., and can solve problems such as waste of fuel, excessive smoke and dust, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

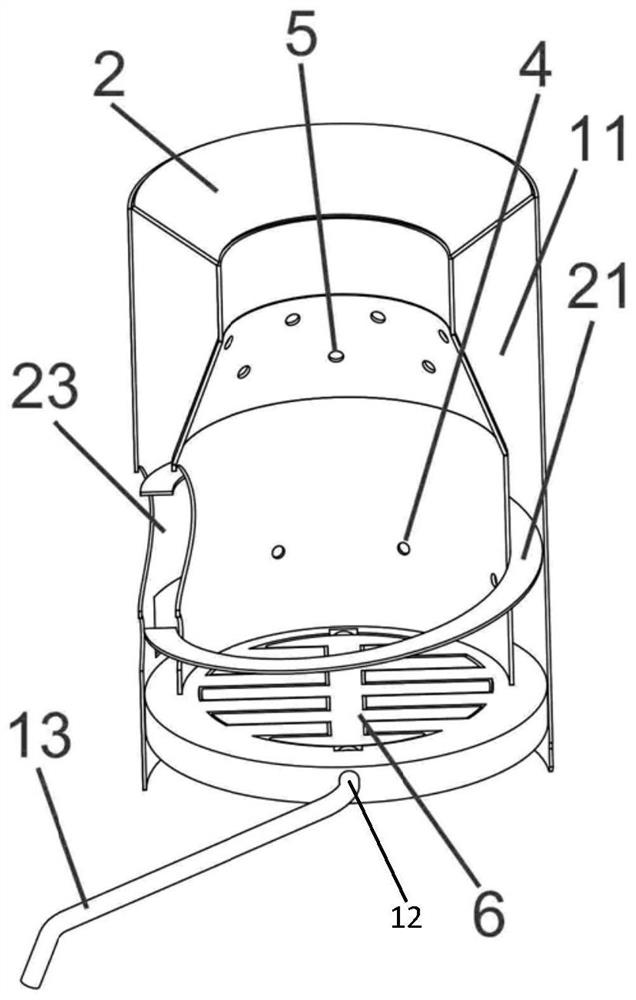

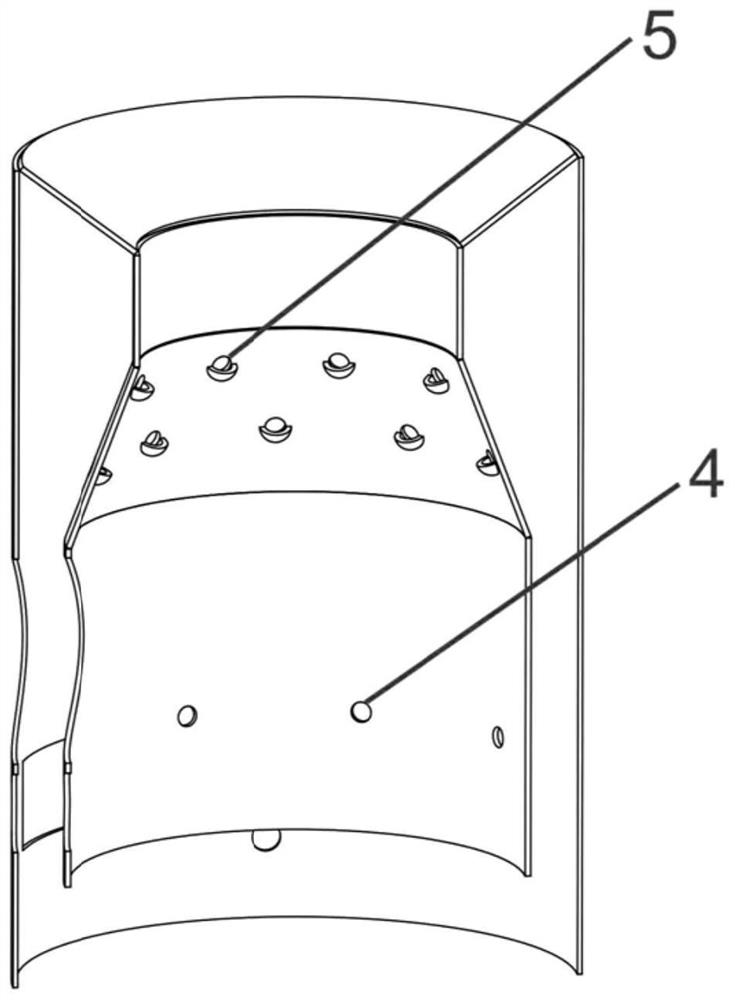

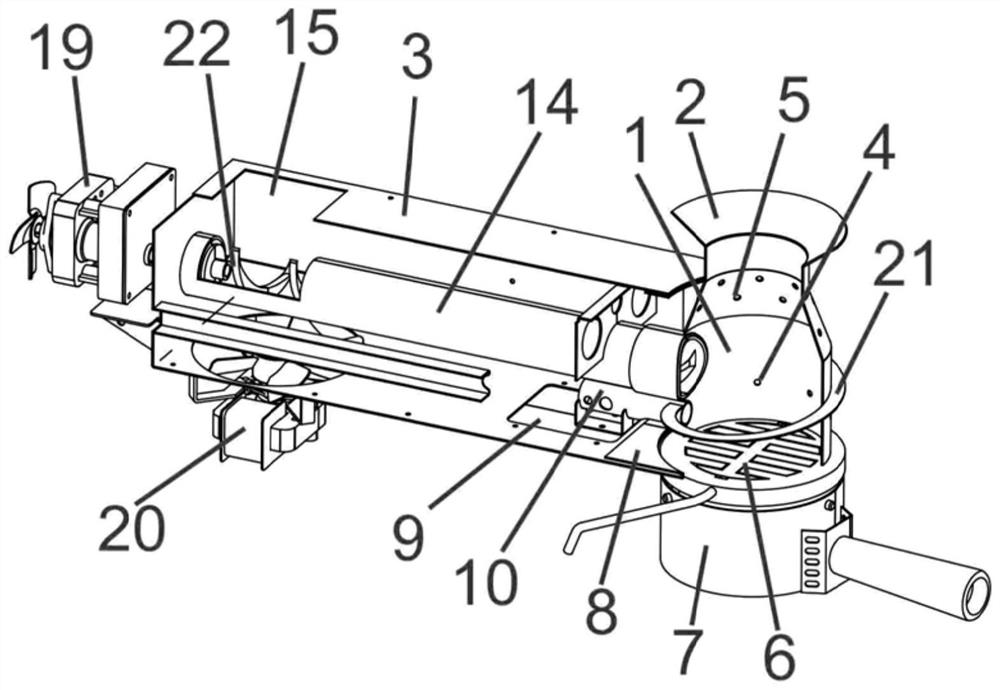

[0029] A combustion box 1 comprises a combustion box wall 2 and a combustion box bottom plate 6 installed at the bottom of the combustion box, the combustion box wall has a hollow interlayer air duct 11 (the combustion box wall is a double-layer structure, and the two ends of the combustion box wall The part is closed and hollow in the middle, and the interlayer of the hollow part is used as air flow), and the bottom and top of the inner wall of the combustion box are respectively provided with a bottom air inlet 4 and a top air inlet 5 that communicate with the interlayer air duct 11, such as figure 1 shown. From figure 1 It can be seen that the combustion box bottom plate 6 is installed on the bottom of the combustion box, and the bottom air inlet hole 4 is located above the combustion box bottom plate 6 . The combustion box outer wall can be provided with the air supply port 23 that communicates with the interlayer air duct 11 according to common knowledge, and the air sup...

Embodiment 2

[0037] Embodiment 2 is substantially the same as Embodiment 1, except that the rotating shaft 12 can be rotated by a motor 16 instead of manual rotation. The free end of the rotating shaft 12 is connected with the servo motor 16. After the movable part of the combustion box bottom plate is electrically driven to rotate 90 degrees by the servo motor 16 through the rotating shaft 12 to become vertical, the slag on the combustion box bottom plate can be smoothly poured under the action of gravity. Put it into the ash box 7 at the bottom of the combustion box, and then the bottom plate will return to the normal horizontal state. Afterwards, the ash box can be taken out to remove the slag and then put it back to the bottom of the combustion box, which saves the need to disassemble the top of the combustion box when cleaning the traditional ash. It takes time and effort to remove the fire cover and drip pan and clean it from above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com