Energy-saving biodegradable fiber brake shoe and wet rolling production technique thereof

A technology for degrading fibers and brake shoes, applied to friction linings, mechanical equipment, etc., can solve the problems of many molds, increase manufacturing costs, and easy generation of dust, achieve uniform friction materials, reduce use costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

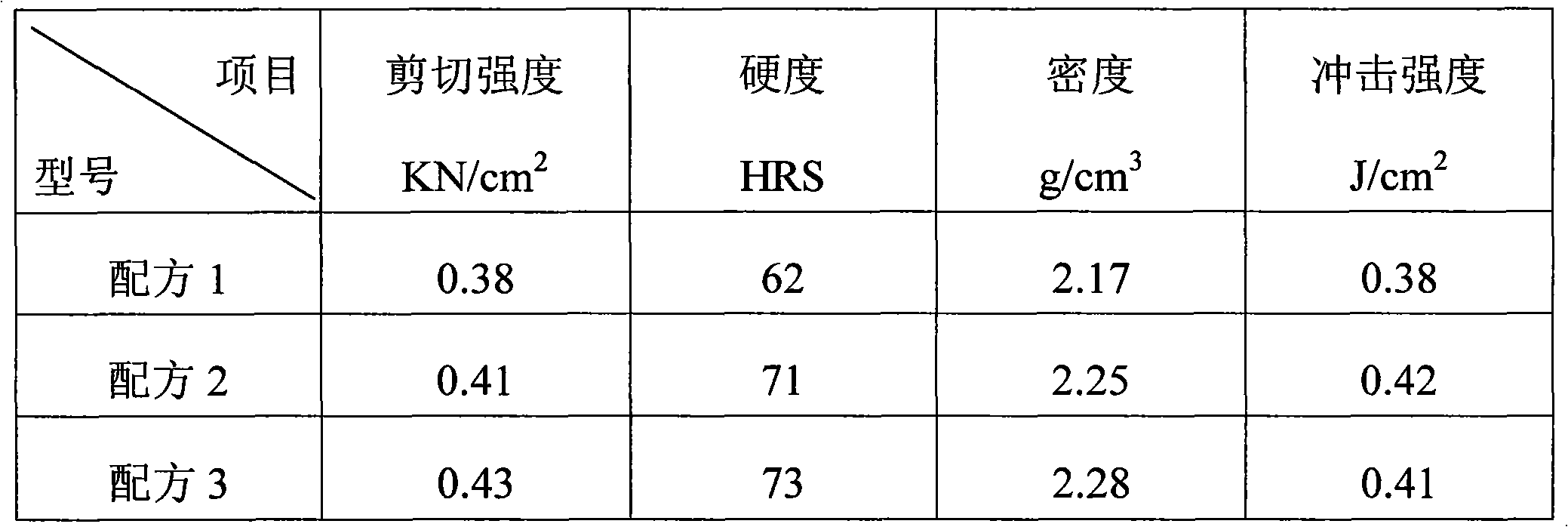

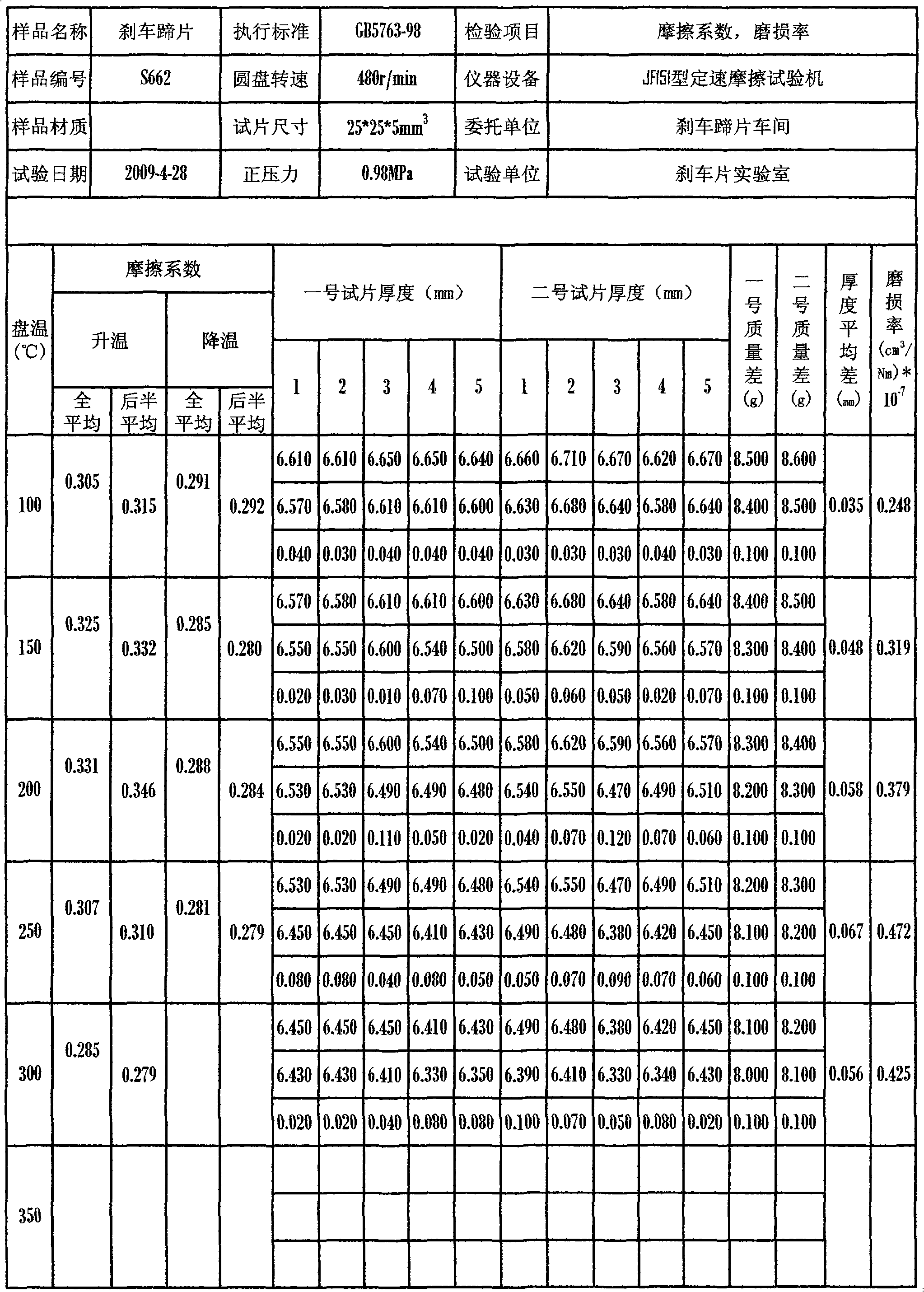

Embodiment 1

[0039] Recipe 1:

[0040] The brake shoe includes a shoe and a friction material bonded on the shoe, and the friction material is composed of the following components by weight: 13 parts of liquid resin, 5 parts of nitrile rubber powder, 3 parts of hexamethylenetetramine, 2 parts of sulfur, 20 parts of mineral fiber, 25 parts of steel fiber, 5 parts of organic fiber, 8 parts of artificial graphite, 8 parts of red iron oxide, 3 parts of wollastonite powder, 4 parts of petroleum coke, and 4 parts of calcium carbonate.

[0041] The process flow using recipe 1 is:

[0042] (1) Batching process: According to the ratio of the formula, the PCS-18 automatic batching system is used for batching to form a prepared dry ingredient. The batching system is fully controlled by the computer. After the batching is completed, the liquid resin will flow into a closed container of the mixer, and the valve will be opened by manual control, so that the liquid resin can flow into the mixer.

[004...

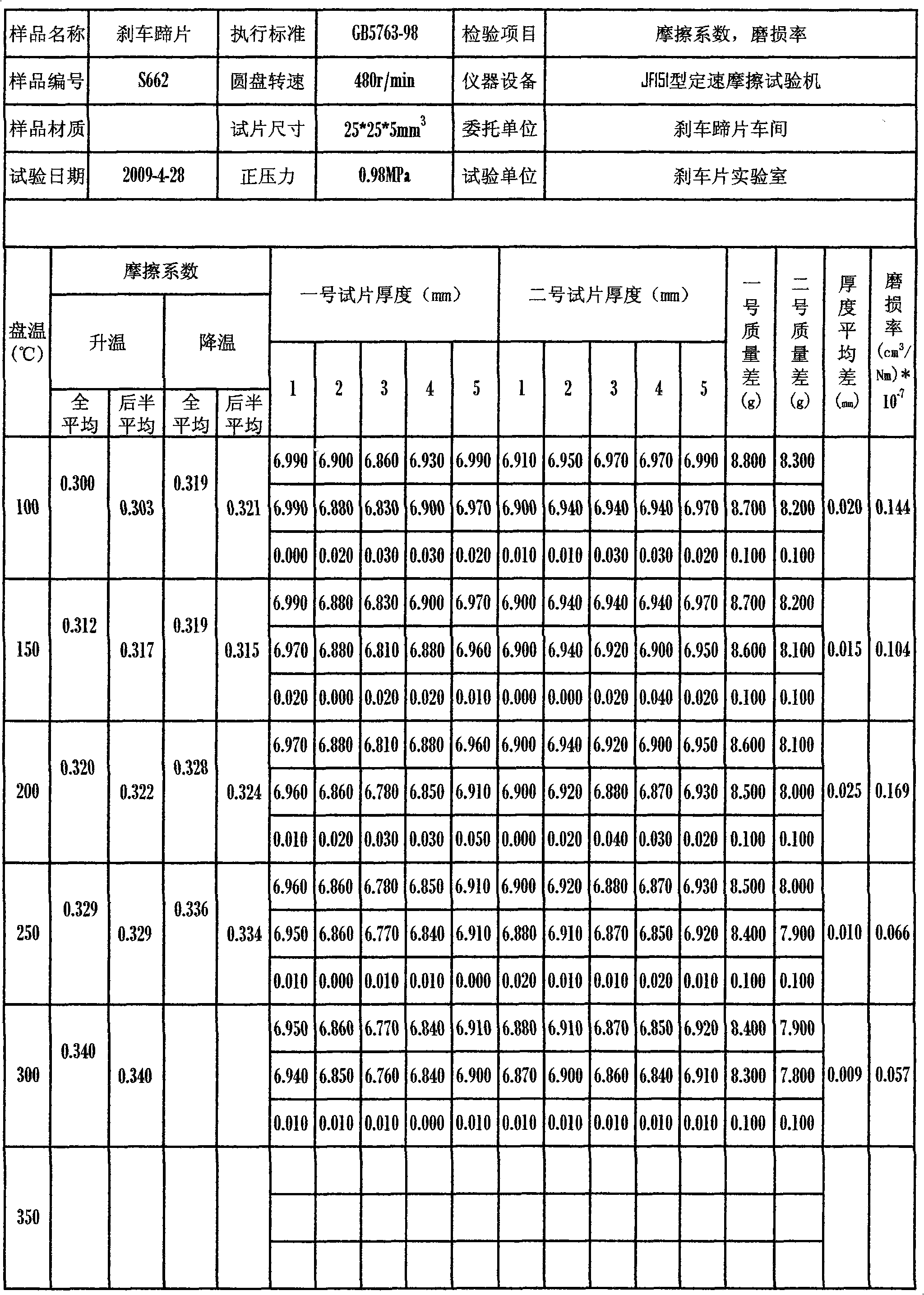

Embodiment 2

[0056] Recipe 2:

[0057] The brake shoe includes a shoe and a friction material bonded on the shoe, and its friction material is composed of the following components by weight: 14 parts of liquid resin, 5 parts of nitrile rubber powder, 3 parts of hexamethylenetetramine, 3 parts of sulfur, 20 parts of mineral fiber, 20 parts of steel fiber, 5 parts of organic fiber, 9 parts of artificial graphite, 9 parts of red iron oxide, 5 parts of wollastonite powder, 5 parts of petroleum coke, and 2 parts of calcium carbonate.

[0058] The process flow using recipe 2 is:

[0059] (1) Batching process: According to the ratio of the formula, the PCS-18 automatic batching system is used for batching, and the batching system is fully controlled by the computer. After the batching is completed, the liquid resin will flow into a closed container of the mixer, and the valve will be opened manually to allow the liquid resin to flow into the mixer;

[0060] (2) Mixing process: first pour the pr...

Embodiment 3

[0072] Recipe 3:

[0073] The brake shoe includes a shoe and a friction material bonded on the shoe, and its friction material is composed of the following components by weight: 14 parts of liquid resin, 6 parts of nitrile rubber powder, 4 parts of hexamethylenetetramine, 4 parts of sulfur, 16 parts of mineral fiber, 20 parts of steel fiber, 4 parts of organic fiber, 7 parts of artificial graphite, 7 parts of red iron oxide, 4 parts of wollastonite powder, 6 parts of petroleum coke, and 8 parts of calcium carbonate.

[0074] The process flow using recipe 3 is:

[0075] (1) Batching process: According to the ratio of the formula, the PCS-18 automatic batching system is used for batching, and the batching system is fully controlled by the computer. After the batching is completed, the liquid resin will flow into a closed container of the mixer, and the valve will be opened by manual control, so that the liquid resin can flow into the mixer.

[0076] (2) Mixing process: first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com