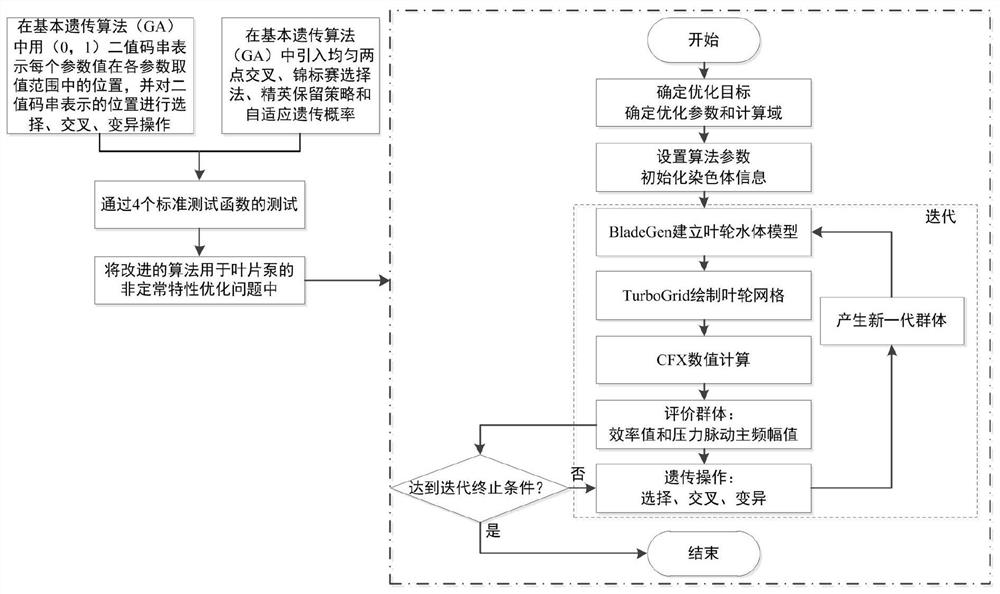

A discrete genetic algorithm-based efficient low-pulsating vane pump optimization method

A genetic algorithm and optimization method technology, applied in the field of high-efficiency and low-pulsation vane pump optimization based on discrete genetic algorithm, can solve problems such as insufficient to effectively solve pump unsteady characteristic optimization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

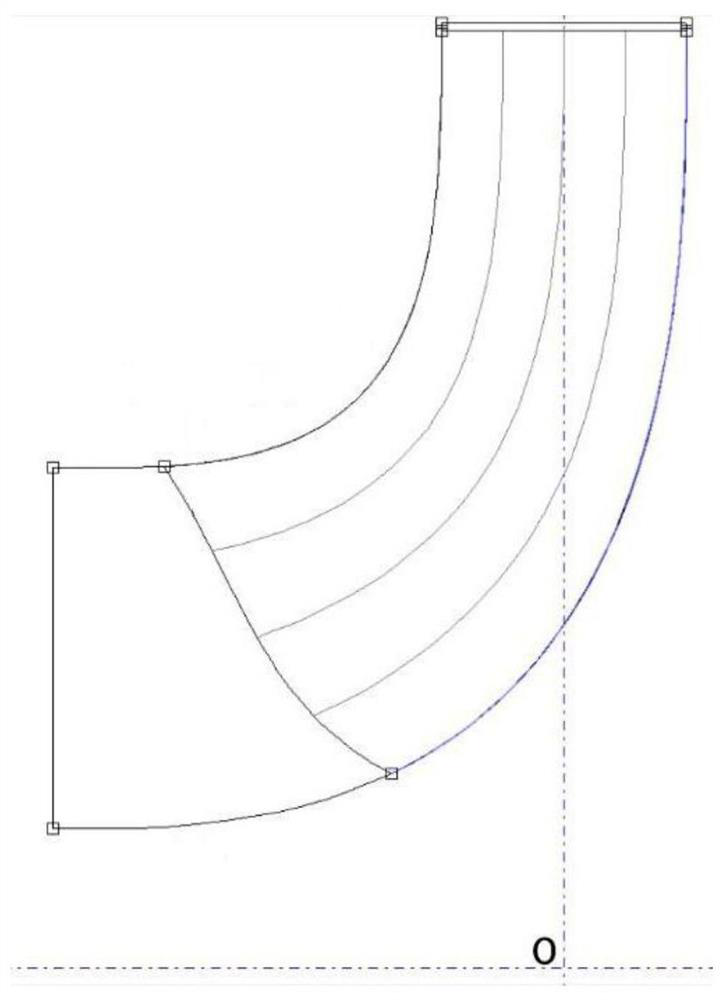

[0109] With a design speed n=2910r / min, flow Q=50m 3 / h, head H = 20m, blade number z = 6 single-stage single-suction centrifugal pump as an example, the axial plane projection diagram is as follows figure 2 shown. The inventive method maintains the impeller inlet width b 1 , impeller inlet diameter D 1 , blade number z, and blade thickness δ remain unchanged.

[0110] Chromosome information was initialized using the Latin hypercube sampling method.

[0111] Call ANSYSBladeGen through ANSYS Workbench for the current chromosome information to perform automatic modeling, the result is as follows image 3 As shown, each chromosome corresponds to an impeller.

[0112] Import the obtained impeller model into ANSYSTurboGrid through ANSYSWorkBench for automatic grid division, the result is as follows Figure 4 shown.

[0113] Substituting the obtained grid and still water grid into ANSYSCFX for constant numerical simulation through ANSYSWorkBench, and using the constant numer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com