Steel rail flaw detection simulation learning practical training instrument, training system platform and practical training method

A technology of simulation learning and training system, which is applied in the field of rail flaw detection simulation learning training instrument, training system platform and practical training, and can solve problems such as failure to keep up with equipment, good rail conditions, and weak flaw detection skills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

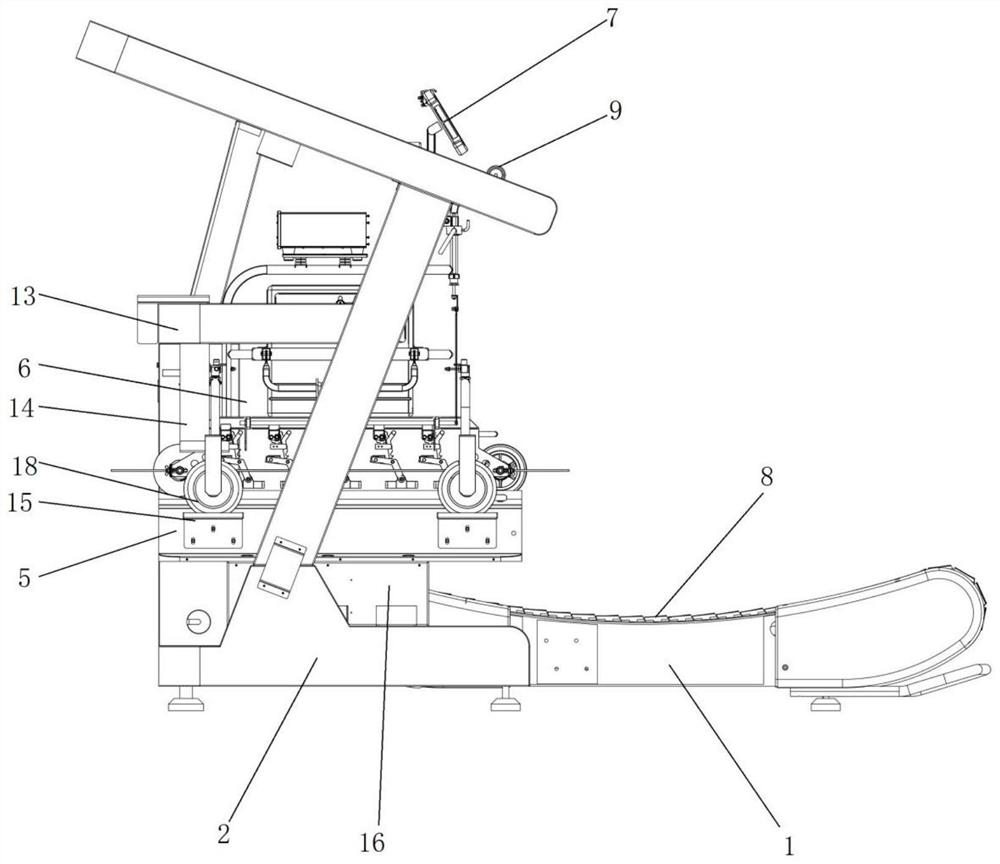

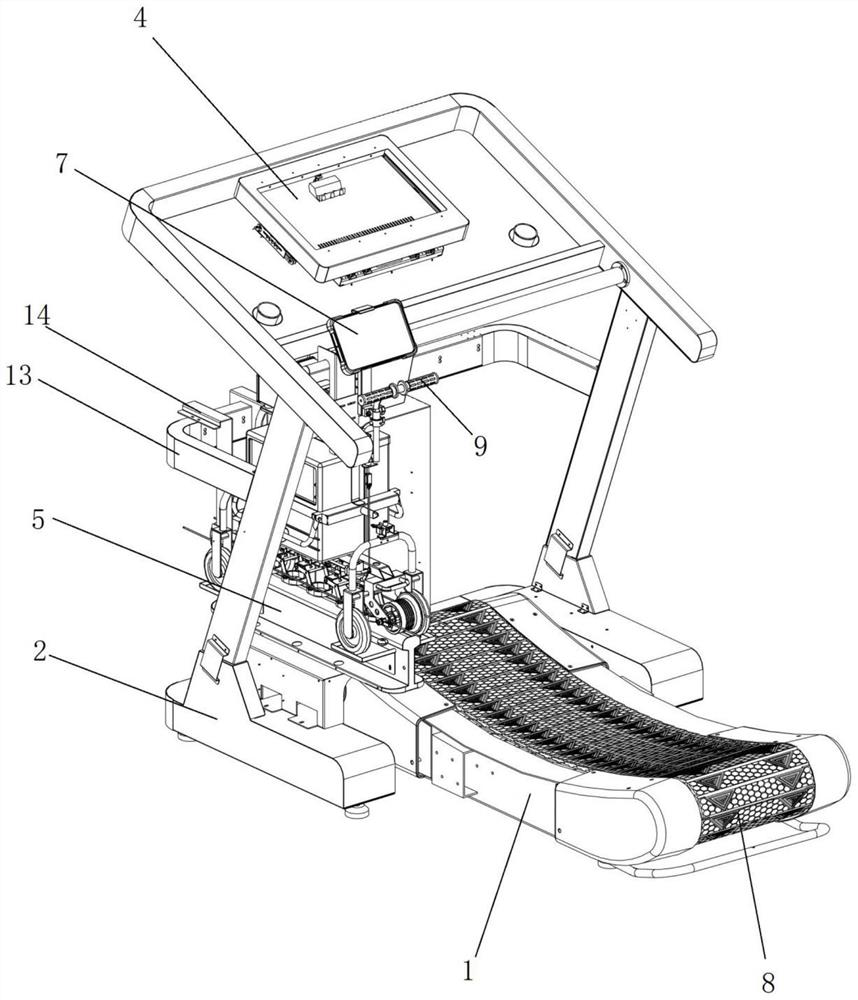

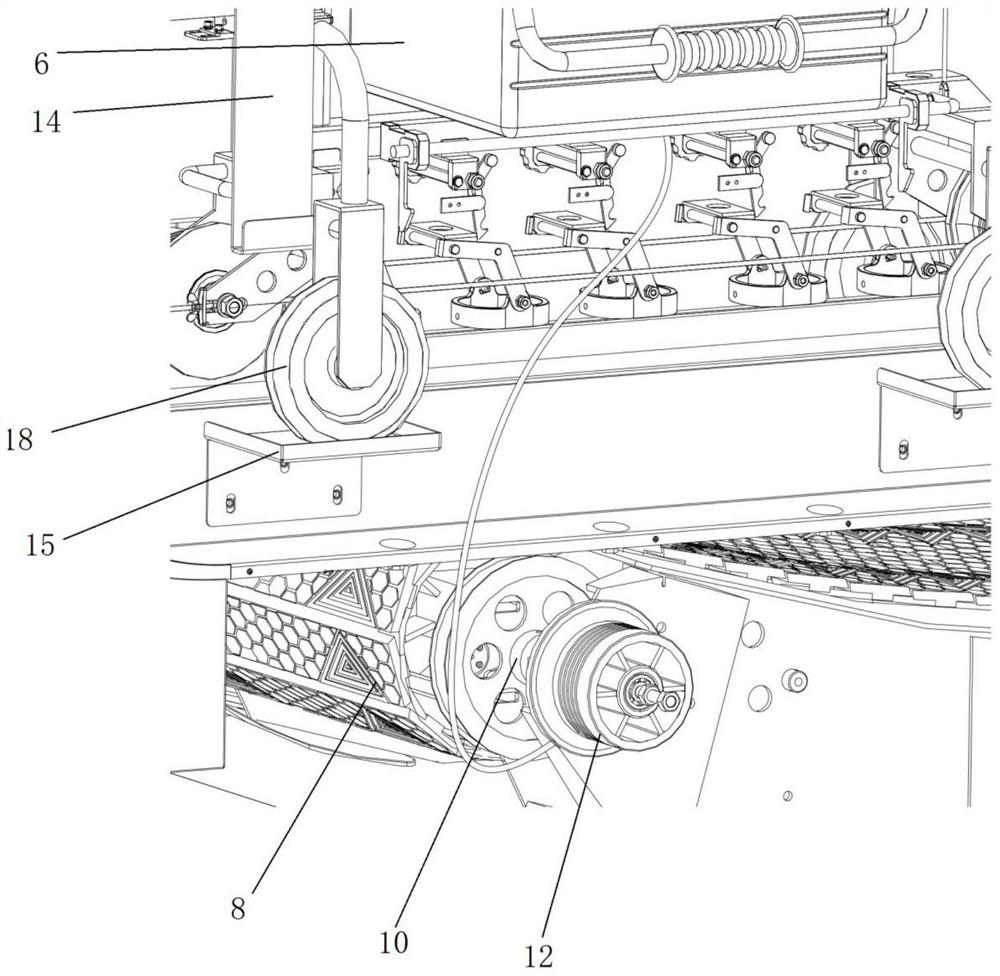

[0037] Embodiment 1: A rail flaw detection simulation learning training instrument, including: a walking chassis 1, a mounting frame 2 installed on the front end of the walking chassis 1, a host computer and an operation display screen 4 are installed on the mounting frame 2, and are mounted on the front end of the walking chassis 1 An imitation rail model 5 is installed on one side, and a rail flaw detector 6 is installed on the imitation rail model 5. The host computer and the operation display screen 4 realize data interconnection with the rail flaw detector 6 in a wired or wireless manner, and the rail flaw detector 6 is installed The oscilloscope 7 is used to display the waveform image of the flaw detection data sent from the host. The trainees stand on the walking tracks 8 of the walking chassis 1, start the main engine and operate the display screen 4, and then carry out the preparatory work before the flaw detection work according to the system language prompts. The su...

Embodiment 2

[0050] Embodiment 2: a rail flaw detection simulation learning training system platform, including:

[0051] Rail damage data resource library: used to collect physical damage waveforms of real rail damages in actual use, and convert physical damaged rails to digital damaged rails to form damage waveform data storage; Qualitative, locating, and quantitative analysis of damage, as the standard answer for damage judgment, and form a database; the collection of damage waveforms, the extraction and conversion of digital damage data, and waveform image data are conventional means, and this embodiment does not introduce the technical details in detail , this rail damage data resource database is to build a damaged track information database based on real track damage data in daily track flaw detection work, including damage waveform images, basic damage information, etc.;

[0052] Walking chassis: including walking tracks, used for students to walk on the spot, and can collect walki...

Embodiment 3

[0072] Embodiment 3: a rail flaw detection simulation learning training method, comprising the following steps:

[0073] S1. Collect physical damage waveforms of real rail damages in actual use, and convert physical damaged rails to digital damaged rails to form damage waveform data storage; and perform qualitative, locating and Quantitative analysis, as the standard answer for injury judgment and form a database;

[0074]

[0075] S2. Load or read the rail damage data resource library, and transmit the damage waveform data to the rail flaw detector in the form of waveform images;

[0076] S3. The speed information and direction information of the trainees walking on the walking track are transmitted to the rail flaw detector, and the received damage waveform image is displayed on the oscilloscope of the rail flaw detector with the received speed information and direction information at the corresponding speed and direction. Come out; 1. It can be controlled artificially a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com