Piglet feed additive for preventing diarrhea and preparation method thereof

A piglet feed and additive technology, applied in the field of animal nutrition, can solve the problems of not being able to maintain health, not producing animal products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

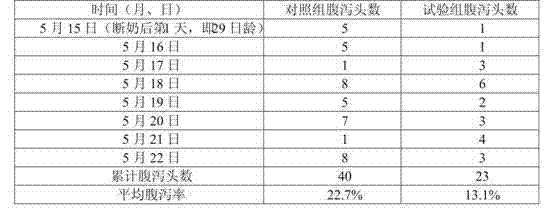

Examples

Embodiment 1

[0014] An anti-diarrhea piglet feed additive is a substance with a molecular weight of 100-1000 Daltons separated from the fermentation product of roughage, and the lignin content in the roughage is less than 10%.

[0015] The preparation method of the above-mentioned anti-diarrhea piglet feed additive comprises:

[0016] Put roughage with a lignin content of less than 10% (corn stalks, alfalfa powder, and bean stalks mixed in a weight ratio of 1:1:1) into the fermentation tank, add starter, heat up to 35°C for anaerobic fermentation for 3 days The ratio of the number of spores of bacillus, yeast, lactic acid bacteria and monascus in the starter is 1:2:1:1, and the total number of active bacteria contained in each gram of fermentation raw material is about 1×10 7 .

[0017] Filter the fermentation product, and then separate the filtrate with a molecular sieve: first use a molecular sieve with a molecular weight cut-off of 1000 Daltons to remove macromolecular substances in th...

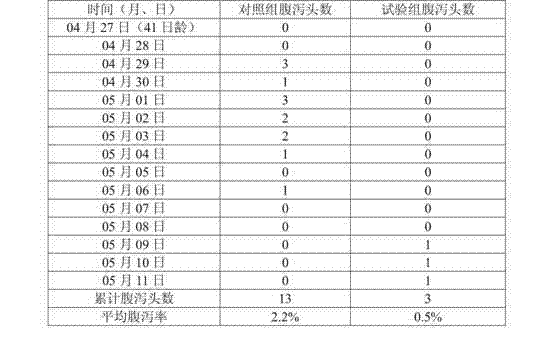

Embodiment 2

[0019] An anti-diarrhea piglet feed additive is a substance with a molecular weight of 100-1000 Daltons separated from the fermentation product of roughage, and the lignin content in the roughage is less than 10%.

[0020] The preparation method of the above-mentioned anti-diarrhea piglet feed additive comprises:

[0021] Select roughage with a lignin content of less than 10% (sweet potato seedlings and wheat straw are mixed at a weight ratio of 2:1) and put them into 4 fermentation tanks respectively, and put Bacillus, yeast, lactic acid bacteria and Monascus into each fermentation tank respectively, The effective live bacteria content in each pool of raw materials is about 1×10 7 Spores / g. Raise the temperature to 40°C, and after two days of fermentation, mix the fermentation products of the four pools according to the weight ratio of 1:2:1:1.

[0022] Filter the fermentation product, and then separate the filtrate with a molecular sieve: first use a molecular sieve with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com