Sleeve rotating device

A technology of rotating device and bushing, applied in switchgear, fully enclosed busbar device, busbar installation, etc., can solve the problem of high bushing, and achieve the effect of reducing height, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

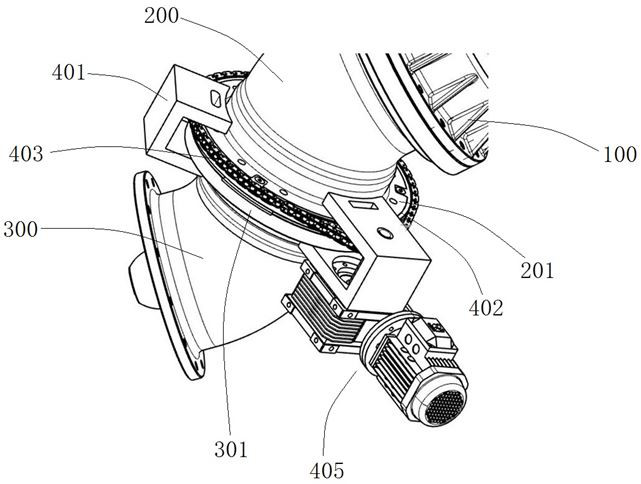

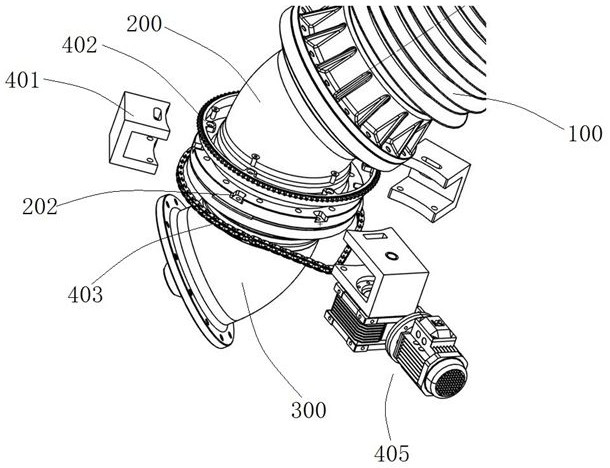

[0043] Such as Figure 1 to Figure 6 As shown, the bushing rotating device is used to drive the bushing cylinder 200 to rotate around the central axis of the bushing cylinder flange 201 and the busbar cylinder flange 301, lower the bushing, and reduce the overall height of the high-voltage switch to facilitate transportation , during on-site installation, reversely rotate the bushing cylinder 200 to erect the bushing upwards again.

[0044] The casing rotation device includes two parts, one part is the limit part, which ensures that the casing cylinder 200 and the casing 100 will not fall during the rotation of the casing; the other part is the driving part, which is used to control the casing cylinder 200 Apply torque to cause rotation.

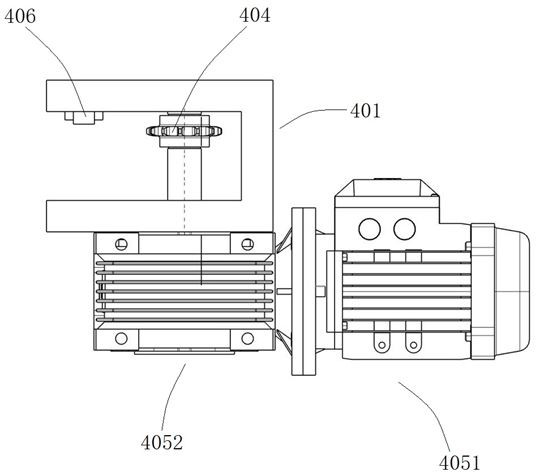

[0045] The limiting part of the present embodiment includes three U-shaped limiting blocks 401, and the structure of the U-shaped limiting blocks 401 is as follows: Figure 5 As shown, the U-shaped limiting block 401 includes an installati...

specific Embodiment 2

[0061] In Embodiment 1, there are protrusions on the split lobes of the sprocket and grooves on the flange of the sleeve cylinder, so that the first sprocket can be integrally fitted outside the flange of the sleeve cylinder. In this embodiment, the sprocket split flap is fixedly installed on one side of the flange of the sleeve body. At this time, the limit side wall of the U-shaped limit block needs to cooperate with the sprocket split flap to prevent the casing barrel from The body and casing are dumped.

specific Embodiment 3

[0063] In Embodiment 1, the first sprocket is fixedly installed on the flange of the sleeve cylinder, and then installed on the sleeve cylinder. In this embodiment, the first sprocket can be fixedly installed on the part of the sleeve cylinder except the flange of the sleeve cylinder. Specifically, each sprocket of the first sprocket is buckled on the sleeve sleeve On the body, bolts and nuts are used to fix each sprocket sub-lobes to each other, and they are tightly fixed on the sleeve barrel by means of clamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com