Low-salt fermented bean curd and preparation method thereof

A technology of salt rot and fermented bean curd, applied in dairy products, cheese substitutes, food science, etc., can solve problems such as bone disease, single shape, and inability to match sweet ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing low-salt fermented bean curd, comprising the following steps:

[0028] a) After mixing the soybean water clear liquid with the wort clear liquid, carry out sterilization treatment to obtain the culture liquid;

[0029] b) Inoculate Sufu Mucor in the culture solution obtained in step a), shake and cultivate in a sterile environment at 20°C to 30°C for 24h to 72h, then filter, add the sterilized seasoning to the obtained clear liquid, and then use sterile water Adjust protease activity to 35U~100U to obtain enzyme system solution;

[0030] c) After sterilizing the tofu base, transfer it to a sterilization container at a product temperature above 60° C., add the enzyme solution obtained in step b) to seal it, carry out fermentation, and finally perform enzyme-killing treatment to obtain low-salt fermented bean curd.

[0031] The invention firstly mixes the soybean water clear liquid and the wort juice clear liquid, and then ca...

Embodiment 1

[0063] (1) Preparation of culture medium: remove impurities and wash soybeans, add 4 times the weight of water, boil for 60 minutes at 115°C-120°C, filter out the clear soybean liquid; Water bath saccharification, after 5.5 hours, check with iodine solution that no blue color is found, filter out the malt residue, add 6wt% egg white liquid and stir evenly, after boiling for 10 minutes, filter out the wort liquid; Mix according to the mass ratio of 1:1, and sterilize at 121°C for 30s before use.

[0064] (2) Preparation of enzyme system liquid: inoculate 10 7 CFU / ml Sufu Mucor, cultured with shaking in a sterile environment at 28°C for 36 hours, added sterilized seasonings to the filtered supernatant (see Table 1), and adjusted protease activity to 48U to 50U with sterile water.

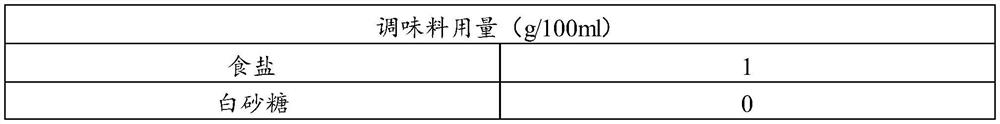

[0065] The seasoning consumption that adds in the embodiment 1 of table 1

[0066]

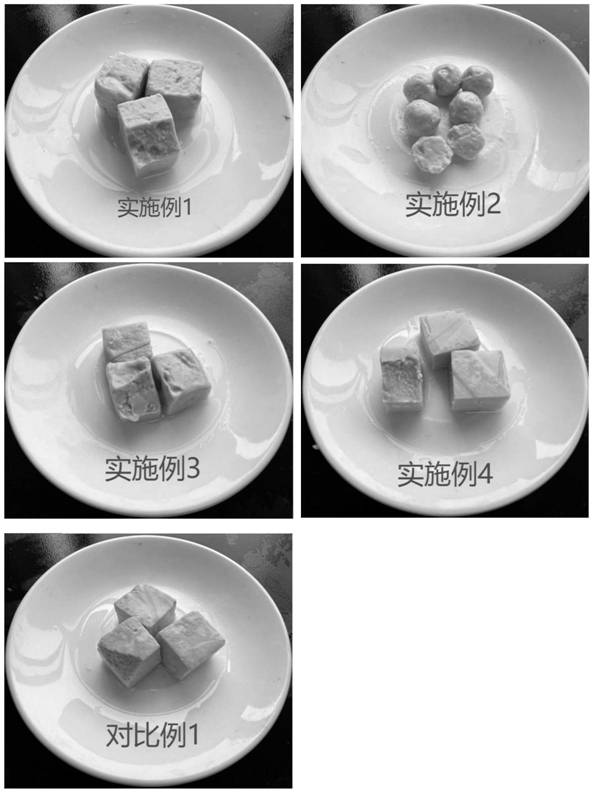

[0067] (3) Bean curd processing: transfer about 2cm×2cm square tofu cubes to sterilized at 90°C for 40 minutes...

Embodiment 2

[0070] (1) Preparation of culture medium: remove impurities and wash soybeans, add 4 times the weight of water, boil for 60 minutes at 115°C-120°C, filter out the clear soybean liquid; Saccharification in water bath, after 5.5 hours, check with iodine solution that no blue color is found, filter out the malt residue, add 6wt% egg white liquid and stir evenly, after boiling for 10 minutes, filter out the wort liquid; Mix according to the mass ratio of 1:1, and sterilize at 121°C for 30s before use.

[0071] (2) Preparation of enzyme system liquid: inoculate 10 7 CFU / ml Sufu Mucor, cultured with shaking in a sterile environment at 28°C for 36 hours, added sterilized seasonings to the filtered supernatant (see Table 2), and adjusted protease activity to 48U to 50U with sterile water.

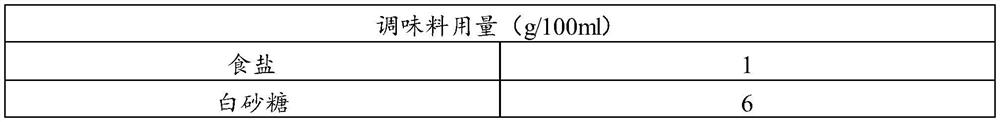

[0072] The seasoning consumption that adds in the embodiment 2 of table 2

[0073]

[0074] (3) Tofu base treatment: Spherical tofu blocks with a diameter of about 1.5 cm are sterilized at a m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap