Die process structure facilitating discharging of fender wheel opening waste and using method

A technology for fenders and scraps, applied in the field of cold stamping dies, can solve the problems of large offset of process parts, the inability of automatic line manipulators to complete the grasping action, and reduce production efficiency, so as to achieve a simple and effective process structure and reduce scrap of parts Quantity, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

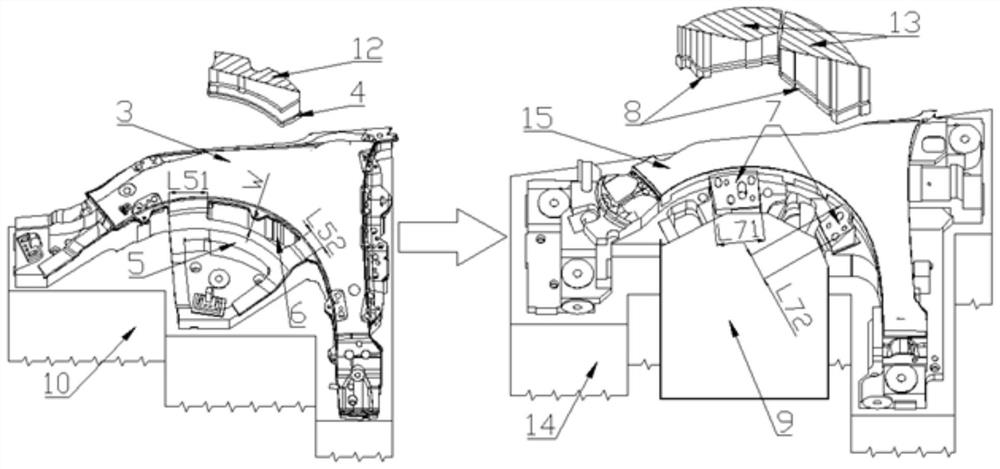

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

[0036] Explanation of some terms recorded in the present invention:

[0037] OP10: also known as the first process, refers to the drawing process;

[0038] OP20: also known as the second process, refers to the trimming and punching process;

[0039] OP30: Also known as the third process, it refers to the process of trimming, punching and flanging.

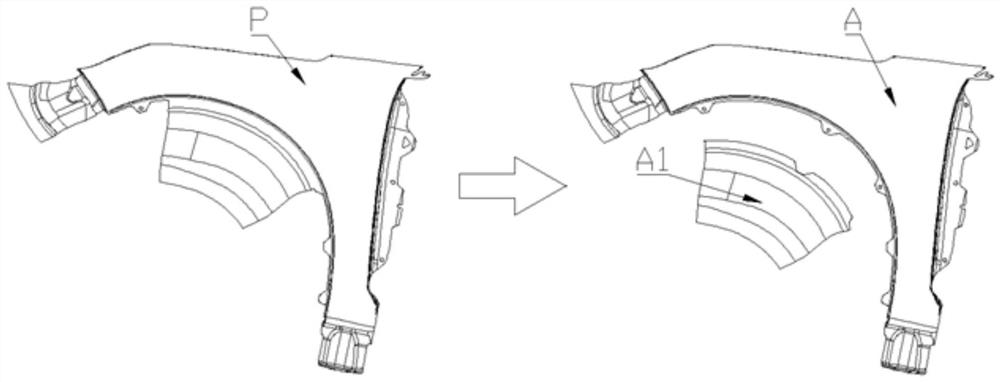

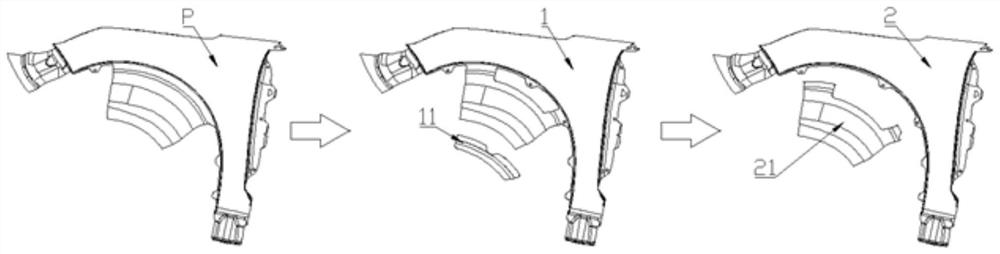

[0040] Such as figure 2 — image 3 As shown, a mold process structure for convenient fender wheel mouth waste discharge, including punching die 6, punching punch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com