Optical fiber automatic focusing method and automatic focusing system for laser processing

An automatic focusing and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor focusing accuracy, difficult to maintain absolute parallelism, and disadvantageous for large-scale fiber grating array preparation, and achieve positioning accuracy. High, fast focus effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

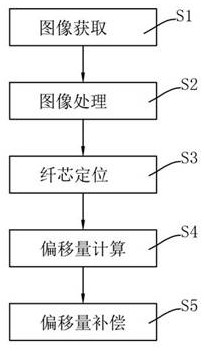

[0157] The existing preparation method does not use segmented sampling and subsequent offset compensation, so the laser position may deviate from the target position on the optical fiber during the preparation process, resulting in a decrease in the performance of the processed structure; at the same time, in the process of array processing It is difficult to guarantee the consistency of each structure in the array, and even the automatic preparation of the array cannot be performed.

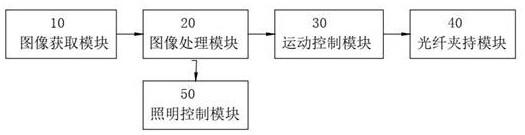

[0158] Further, the motion control module 30 also includes a rotation motion control module 34, such as Figure 8shown. The rotation motion control module 34 is specifically used to rotate the optical fiber, so as to align the target position on the optical fiber at different positions of the multi-core optical fiber, such as the core, to the area to be processed. In this scenario, the rotational motion control module 34 can control the rotation of the optical fiber clamp, for example, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com