Real-time laser automatic focusing device and method

An automatic focusing and laser technology, applied in installation, optics, optical components, etc., can solve problems such as large influence, complex device and method, and unsatisfactory focusing precision and accuracy, achieving a wide range of applications, simple device, focusing Precision adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

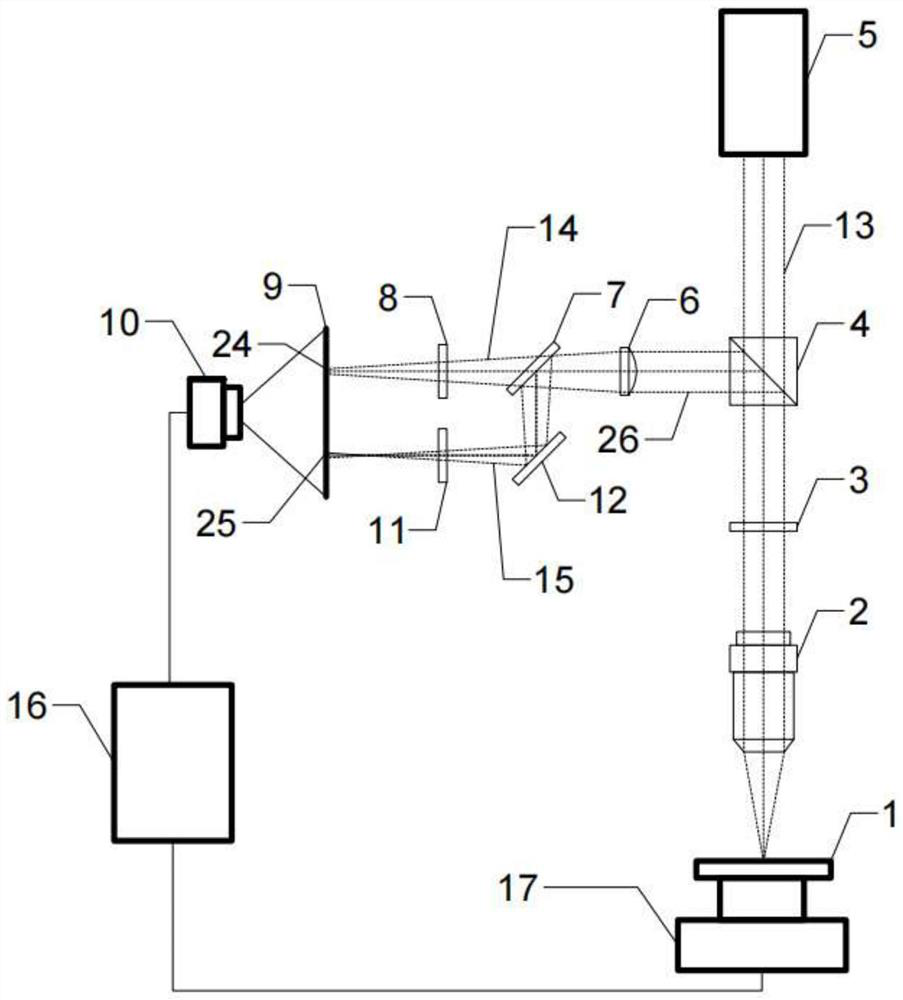

[0024] Embodiment 1: Implementation method of real-time laser autofocus device.

[0025] like figure 1 As shown, in the initial state, the moving platform 17 is located at point (X0, Y0, Z0), and the laser is in a focused state. When the motion platform moves according to the set trajectory, the position of the sample to be tested 1 relative to the microscope objective lens changes all the time. At the same time, the laser beam 13 passes through the polarization beam splitter 4, the 1 / 4 wave plate 3, and the microscope objective lens 2 in turn, and is reflected on the surface of the sample 1, and the reflected light then passes through the microscope objective lens 2, the 1 / 4 wave plate 3, and polarized beam splitter With mirror 4, the polarization state is changed so that the incident light and the reflected light are separated.

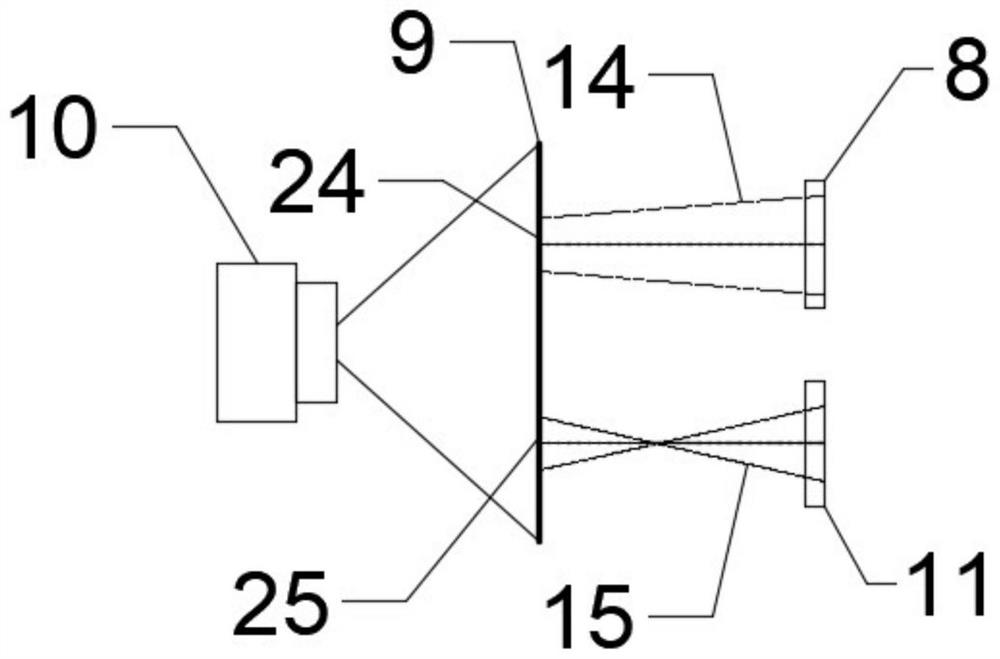

[0026] The reflected light beam 26 passes through the focusing lens 6, and the beam splitter 7 is divided into two beams of light 14 and 15. The...

Embodiment 2

[0031] Embodiment 2: A real-time laser autofocus method.

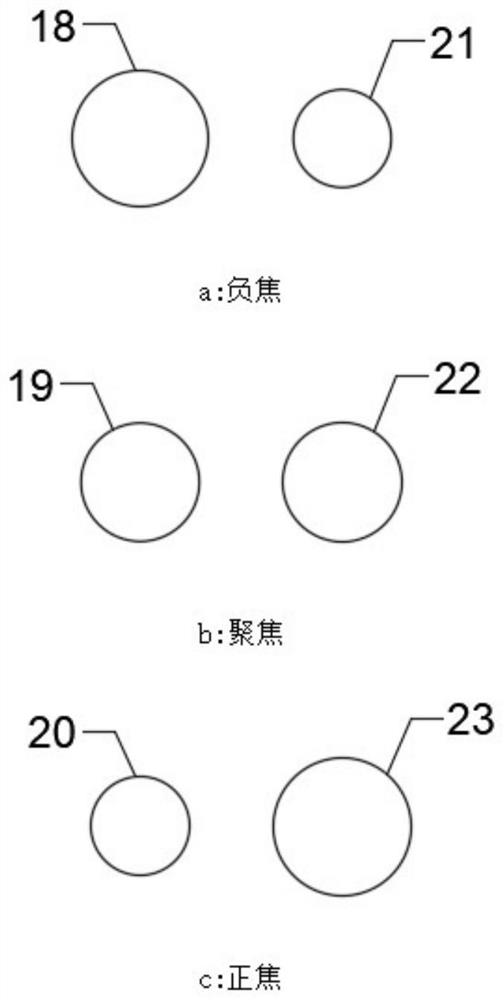

[0032] The image is collected by the image acquisition camera, and the camera can use CCD or COMS, etc. First, grayscale and binarize the collected images in turn, convert the grayscale value of the pixel in the grayscale range of 60-255 in the original image to 255, and then filter the binarized image through a low-pass filter High-frequency noise in the image, and then fill and repair the image to obtain a solid target image, then erode and expand the image to make the edges smoother, then mask the target image, and use the function to calculate the center position of the spot ;

[0033] Obtain the center positions of the two light spots, and calculate the width of the gray value in two arbitrary orthogonal directions passing through the center positions, and obtain the diameter of the binarized target image. During the real-time acquisition process, due to the light intensity of the light source Larger, the light ...

Embodiment 3

[0034] Embodiment 3: A real-time laser autofocus method.

[0035] The specific image processing method is consistent with Embodiment 2, the difference is to calculate the area of the two target images after the binarization process, the area can be calculated by the software's own algorithm or the area can be calculated by using the above-mentioned diameter; and according to the two spot areas The difference is used as a focusing error signal, which is used to control the Z-axis of the motion platform 17, so as to drive the sample 1 to be tested to move up and down to achieve focusing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com