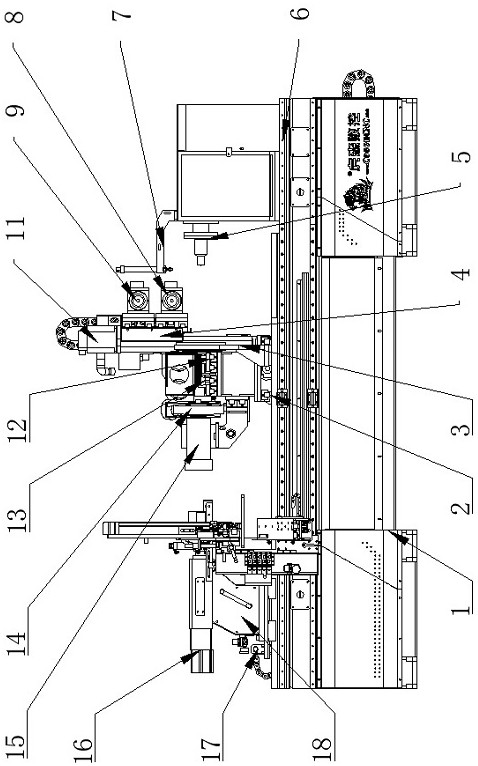

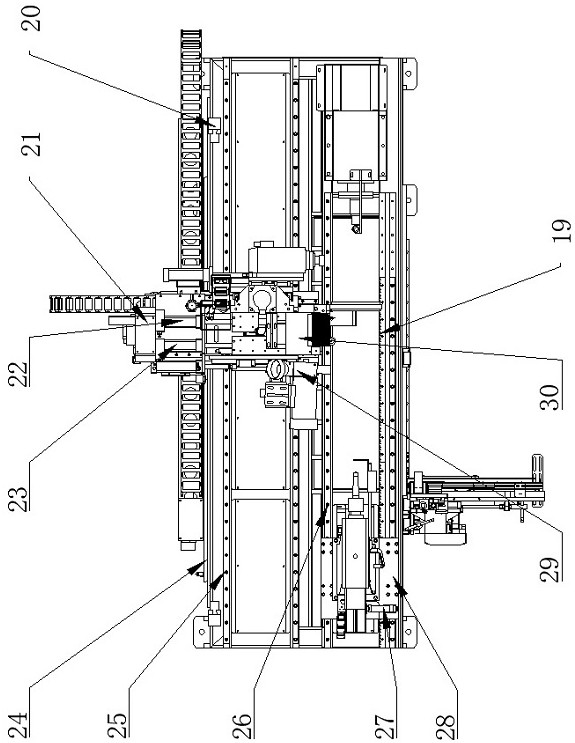

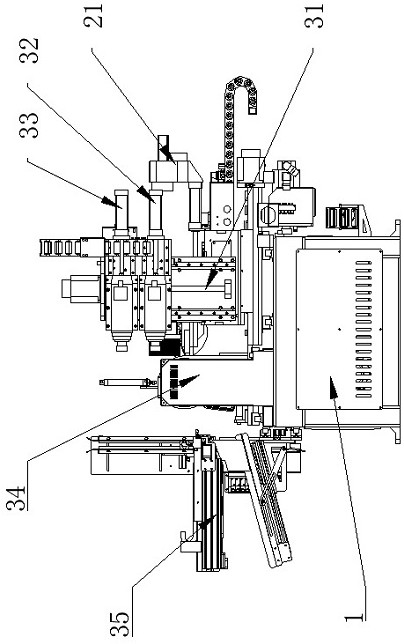

Woodworking numerical control machining center capable of achieving automatic feeding

A processing center and automatic feeding technology, which is applied in the field of wood processing, can solve the problems of single operation steps of machine tools, affect production efficiency, and high labor intensity, and achieve the effects of high degree of automation, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following are only specific embodiments of the present invention, but the protection scope of the present invention is not limited thereto, and any changes or substitutions that can be easily conceived by those skilled in the art within the technical scope disclosed in the present invention shall be covered. Within the protection scope of the present invention.

[0033] The words "front", "rear", "inner" and "outer" described in the present invention to describe the relationship between directions are only for the convenience of description of the embodiment, and are not considered to limit the present invention. The "first", "second" and so on are only used for distinguishing descriptions, and should not be understood as indicating or implying relative importance. The fixed connection methods include but are not limited to welding, screwing, clamping, interference fit, and integral molding.

[0034] The "left" referred to below is the side where the tailstock 18 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com