Aluminosilicate strengthened glass and preparation method thereof

A technology of aluminosilicate glass and reinforced glass, which is applied in the field of glass manufacturing to achieve the effects of perfect glass network structure, high processing efficiency and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

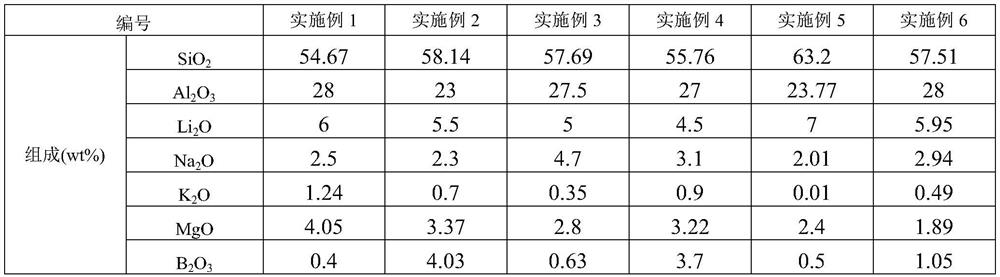

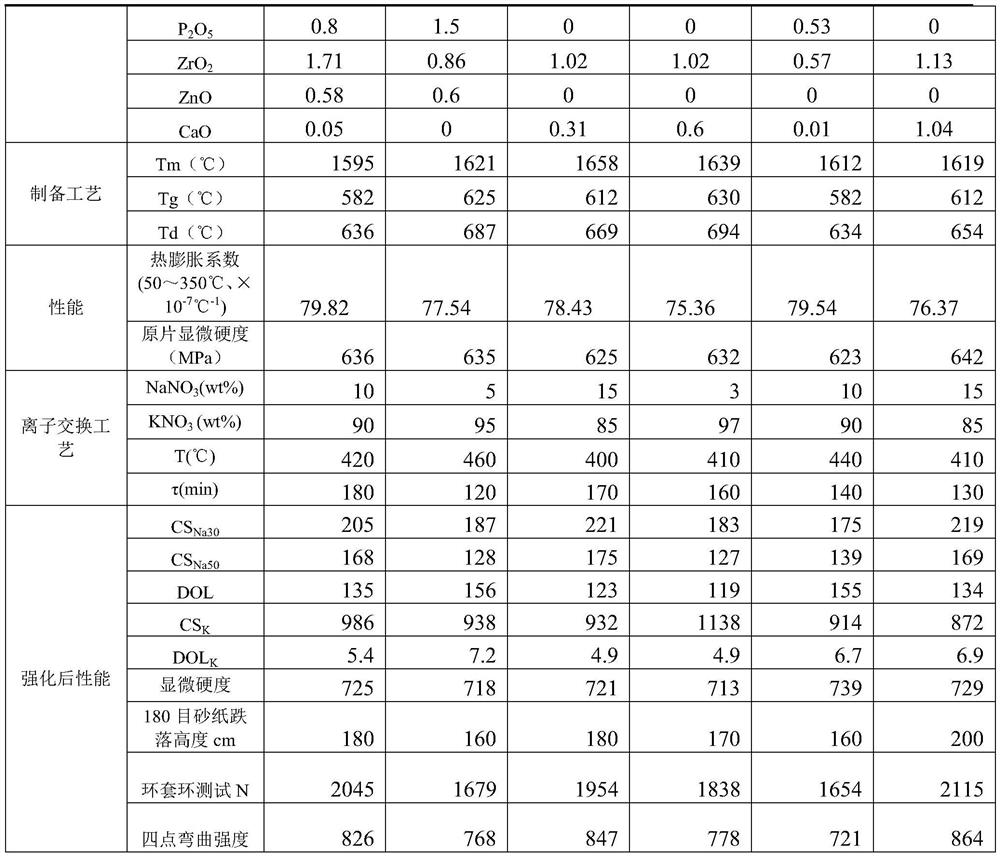

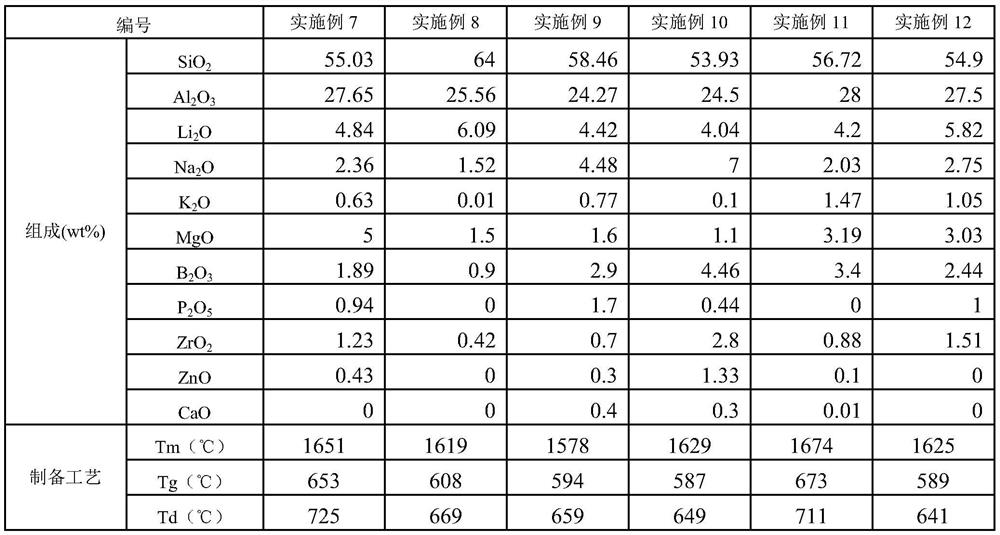

Examples

preparation example Construction

[0063] The present invention also provides the preparation method of the aluminosilicate strengthened glass, comprising the following steps:

[0064] Mixing the raw materials according to the composition of the above-mentioned aluminosilicate glass, performing melting treatment, then annealing and forming to prepare the aluminosilicate glass; and

[0065] Immersion of aluminosilicate glass in NaNO 3 and KNO 3 Ion exchange is carried out in mixed molten salts to prepare the aluminosilicate strengthened glass.

[0066] The specific preparation process of the aluminosilicate glass involved in the present invention can be obtained in the traditional flat glass manufacturing process, and its manufacturing process is not limited to the float forming process, overflow down-draw method, lead-up method, flat drawing method, and calendering method Wait.

[0067] In one example, the melting temperature ranges from 1500°C to 1700°C.

[0068] In one example, the annealing temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com