Antibacterial melt-blown cloth and preparation method thereof

A production method, melt-blown cloth technology, applied in the field of sterilization and antibacterial, to achieve the effect of antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] As shown below, an antibacterial melt-blown cloth is provided, consisting of the components described in Table 1:

[0027]

[0028] (Table I)

[0029] The antibacterial melt-blown cloth made by Example 1: its filterability ≥ 95%, its single-layer air resistance ≤ 50Pa, its antiviral activity rate ≥ 93% to H1NI influenza virus, the bacteriostatic rate of Mycobacterium chelonis ≥ 96%, Staphylococcus aureus bacteriostatic rate ≥ 97%, Candida albicans bacteriostatic rate ≥ 93%.

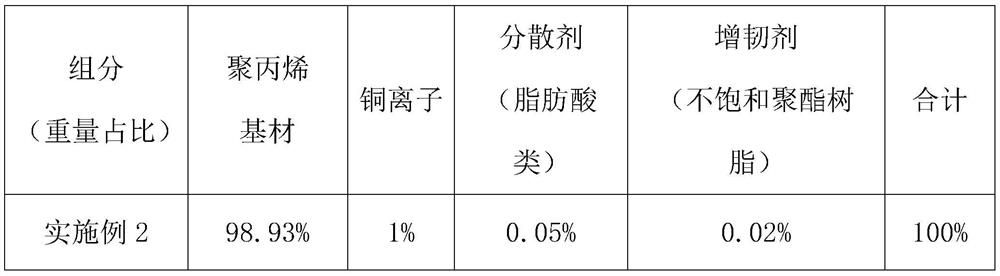

Embodiment 2

[0031] As shown below, an antibacterial melt-blown cloth is provided, consisting of the components described in Table 2:

[0032]

[0033] (Table II)

[0034] The antibacterial melt-blown cloth made by Example 2: its filterability ≥ 95%, its single-layer air resistance ≤ 50Pa, its antiviral activity rate ≥ 99% to H1NI influenza virus, the bacteriostatic rate of Mycobacterium chelonis ≥ 99%, Staphylococcus aureus bacteriostatic rate ≥ 99%, Candida albicans bacteriostatic rate ≥ 96%.

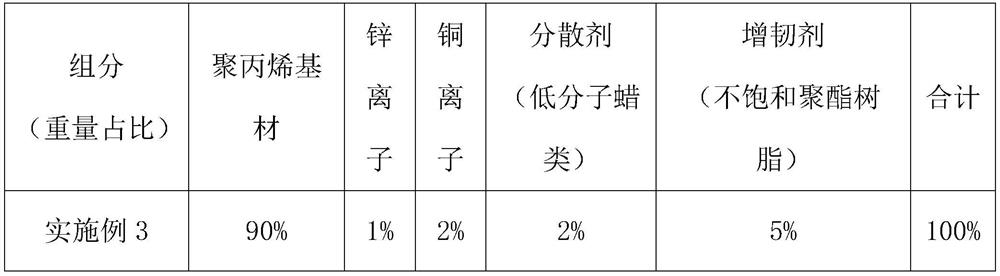

Embodiment 3

[0036] As shown below, an antibacterial melt-blown cloth is provided, consisting of the components described in Table 3:

[0037]

[0038] (Table 3)

[0039] Antibacterial meltblown cloth made by Example 3: its filterability ≥ 95%, its single-layer air resistance ≤ 50Pa, its antiviral activity rate ≥ 99% to H1NI influenza virus, bacteriostatic rate of Mycobacterium chelonis ≥ 99%, Staphylococcus aureus bacteriostatic rate ≥ 99%, Candida albicans bacteriostatic rate ≥ 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com