Heat supply pipeline leakage detector based on magnetism, heat, sound, electricity and humidity trenchless detection

A leak detector and heating pipeline technology, which is applied to pipeline systems, uses electrical devices to test fluid tightness, and detects the appearance of fluid at leak points, etc., can solve the problem that it is difficult to quickly and accurately determine the leak point of trenchless heating pipeline , Inefficiency, waste of time, manpower, material resources and other problems in the repair work of leakage of heating pipes, to achieve the effect of saving manpower and material resources, simple and ingenious structure, fast and accurate search

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

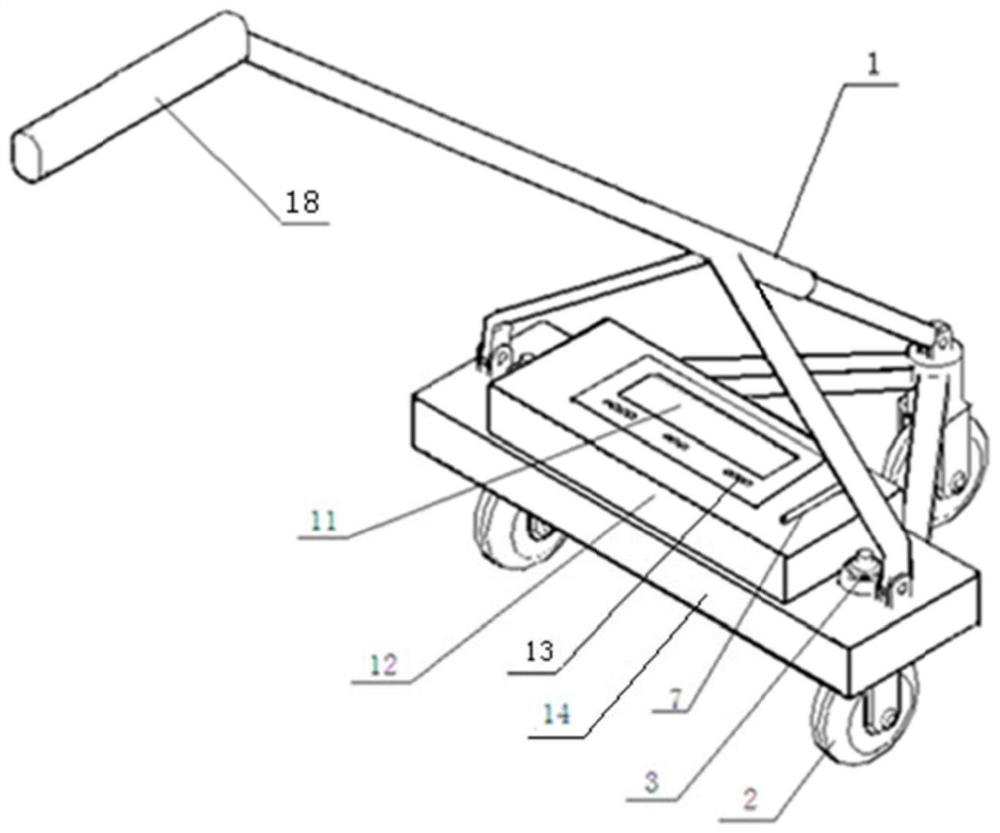

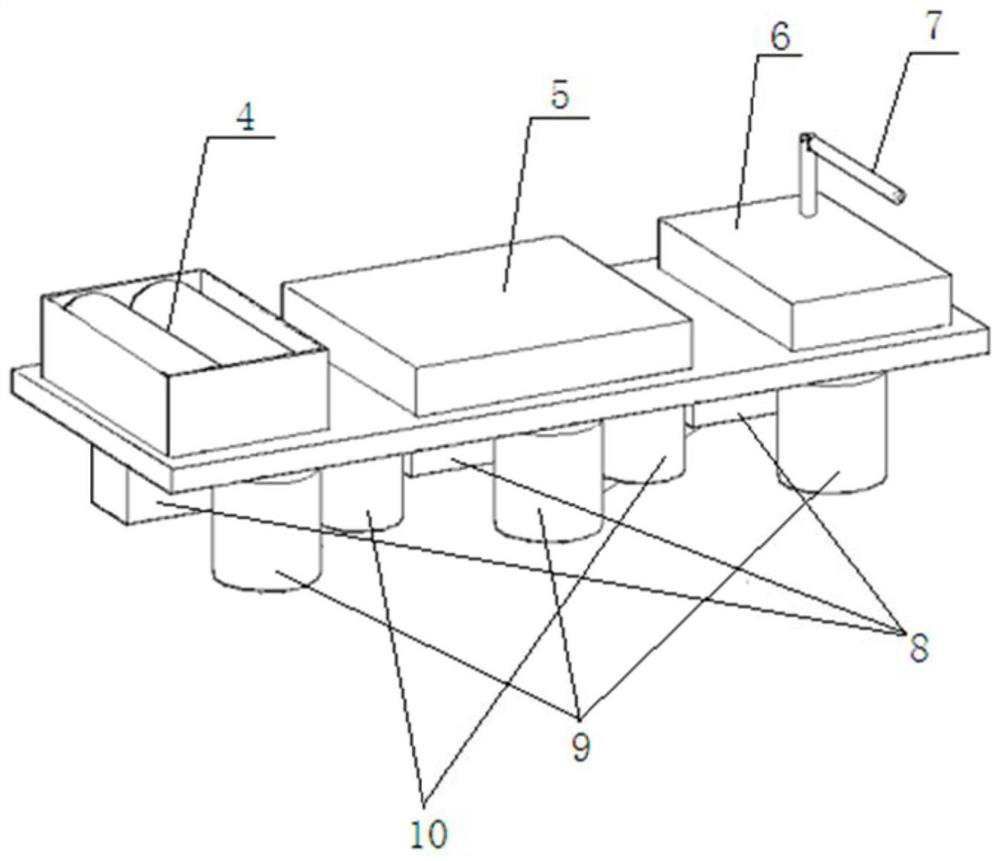

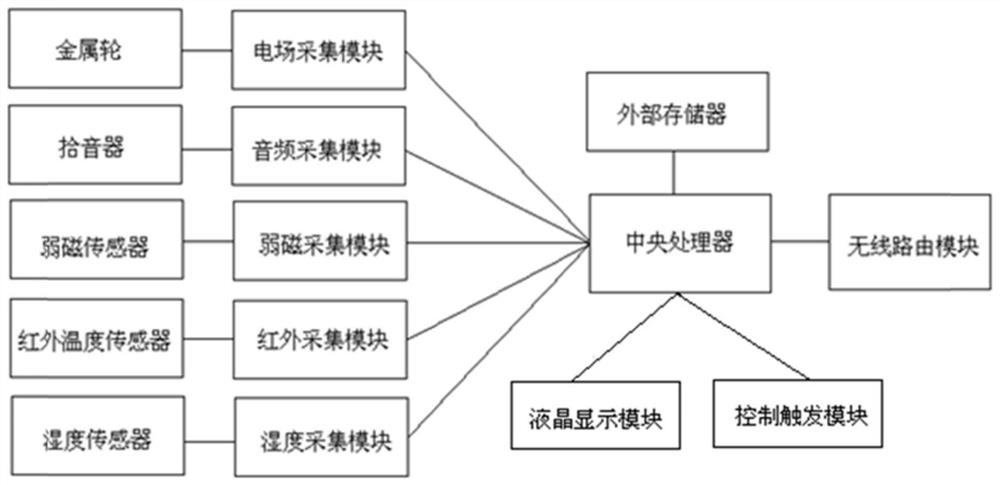

[0029] This embodiment provides a heating pipeline leak detector based on magnetic, thermal, acoustic, electric and wet non-excavation detection, such as Figure 1 to Figure 4 As shown, it includes a bracket 1, a metal wheel 2, a pickup 3, and a data collection center; wherein, the bracket 1 is made of a non-ferromagnetic, non-conductive material, and the bracket 1 is composed of a telescopic rod 15, a structural frame 16, and a thin bottom plate 17 connected; the three metal wheels 2 are installed on the structural frame 16, and the arrangement positions of the three metal wheels 2 are triangular; the pickup 3 is made of non-metallic material, and the pickup 3 is located on the above the metal wheel 2 and connected with the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com