Method for predicting particle fouling thermal resistance by using Euler method based on numerical simulation

A numerical simulation, fouling thermal resistance technology, applied in CAD numerical modeling, special data processing applications, electrical digital data processing, etc., to achieve reliable data support, ensure accuracy, and simplify complex problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to further understand and implement the present invention, the present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

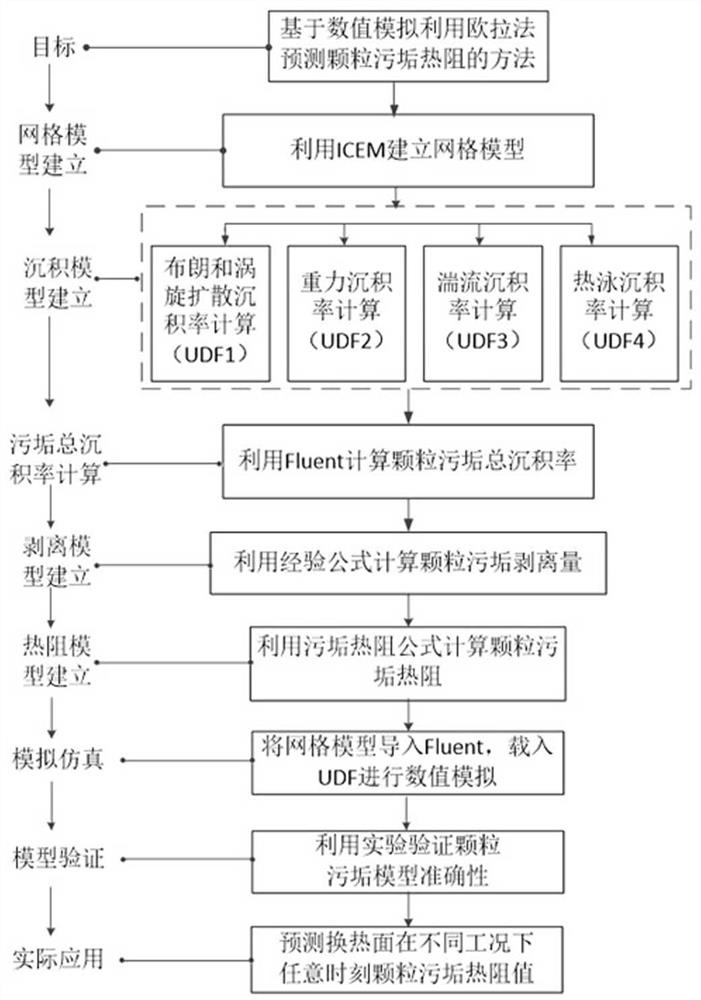

[0069] combine figure 1 , a method for predicting the thermal resistance of particulate dirt based on numerical simulation using the Euler method in this embodiment, the steps are as follows:

[0070] S1. Establish grid model

[0071] Based on the specific shape and size of the heat exchange equipment, a mesoscopic three-dimensional geometric model of the sewage heat exchange equipment is established. According to the actual situation in the calculation domain, ICEM CFD software is used to divide the unstructured tetrahedral mesh, so as to realize the discrete calculation domain.

[0072] In order to accurately simulate the flow field of sewage in the heat exchange equipment, grid independence verification must be carried out. The specific verification method is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com