Micro OLED display and production method thereof

A production method and a display technology, which are applied in the field of MicroOLED display, can solve the problems of uneven spin coating of organic layers and organic planarization layers and the matching of encapsulation layers, and achieve the effects of avoiding uneven spin coating, high efficiency, and simplified processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A production method of a Micro OLED display, comprising the following steps:

[0036] (1) Prepare a CMOS drive circuit on a silicon wafer substrate to obtain a substrate, and prepare an AMOLED light-emitting layer on the substrate according to the pixel arrangement structure;

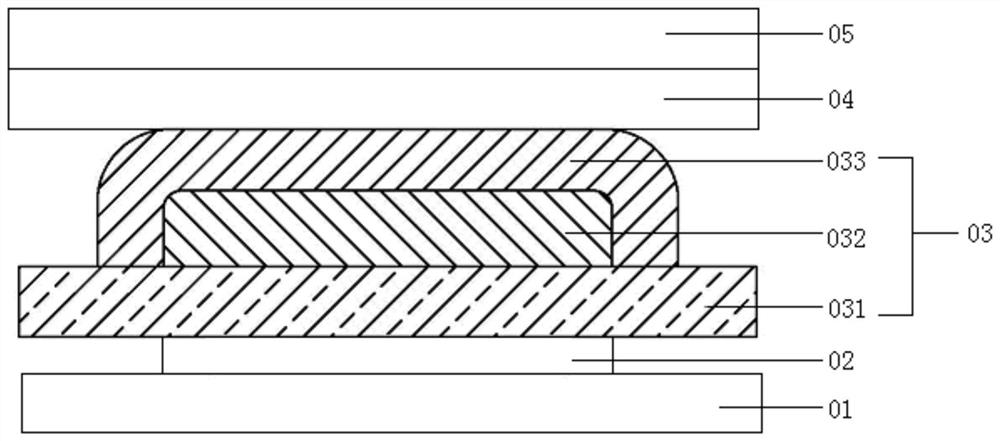

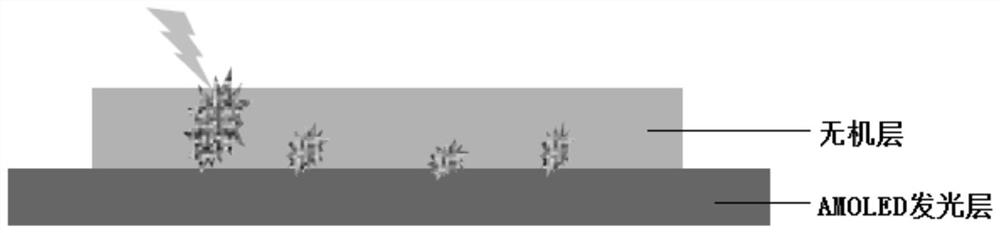

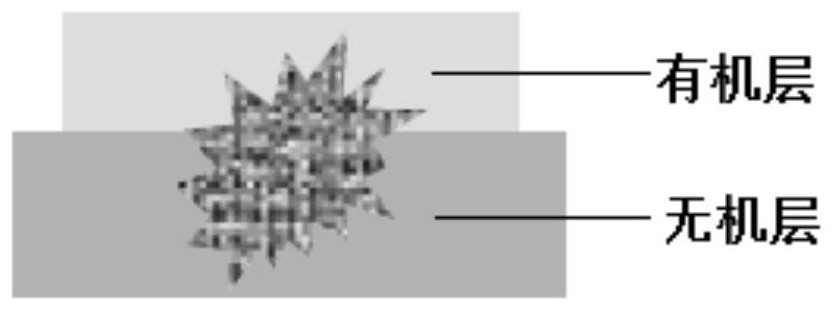

[0037] (2) A first inorganic layer is prepared on the AMOLED light-emitting layer, and an organic layer is prepared by inkjet printing on the first inorganic layer, and the area of the organic layer is smaller than that of the first inorganic layer area, preparing a second inorganic layer on the outer surface of the organic layer to obtain an encapsulation layer positioned on the AMOLED light-emitting layer;

[0038] (3) preparing an organic planarization layer by inkjet printing on the encapsulation layer;

[0039] (4) performing RGB coating on the organic buffer layer to form a color filter layer.

[0040] The material of the organic planarization layer is acrylic resin, and the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com