Miniaturized multi-frequency antenna and manufacturing method thereof

A technology of multi-frequency antenna and manufacturing method, which is applied in the directions of antenna, antenna coupling, resonant antenna, etc., and can solve the problems affecting the quality and damage of multi-frequency antenna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

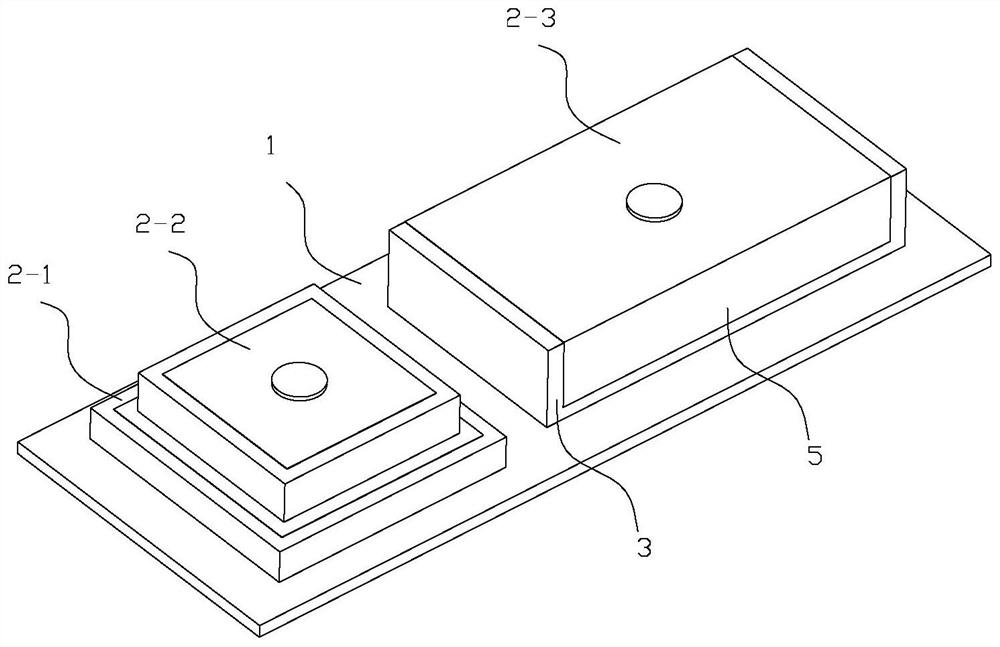

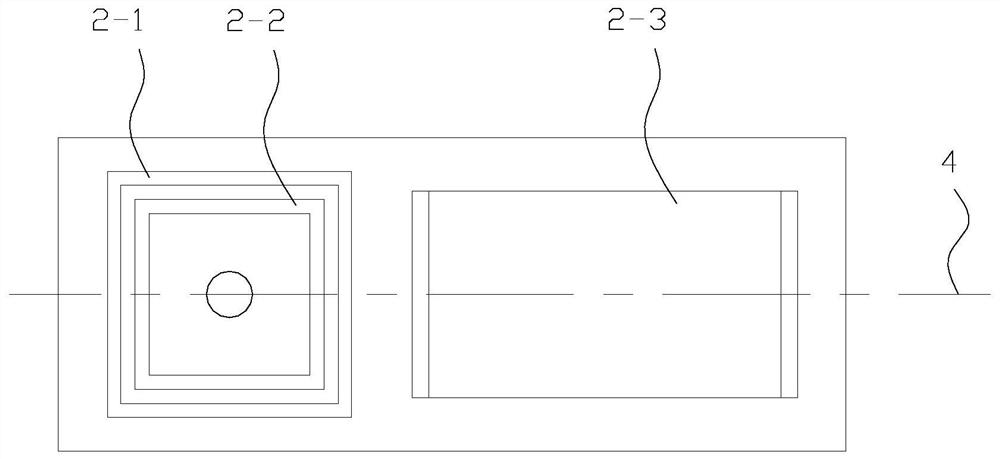

[0046] Method 1: If figure 2 As shown, a diagonal of the square is 45° to the central plane;

[0047] Method 2: If Figure 4 As shown, a diagonal of the square coincides with the central plane.

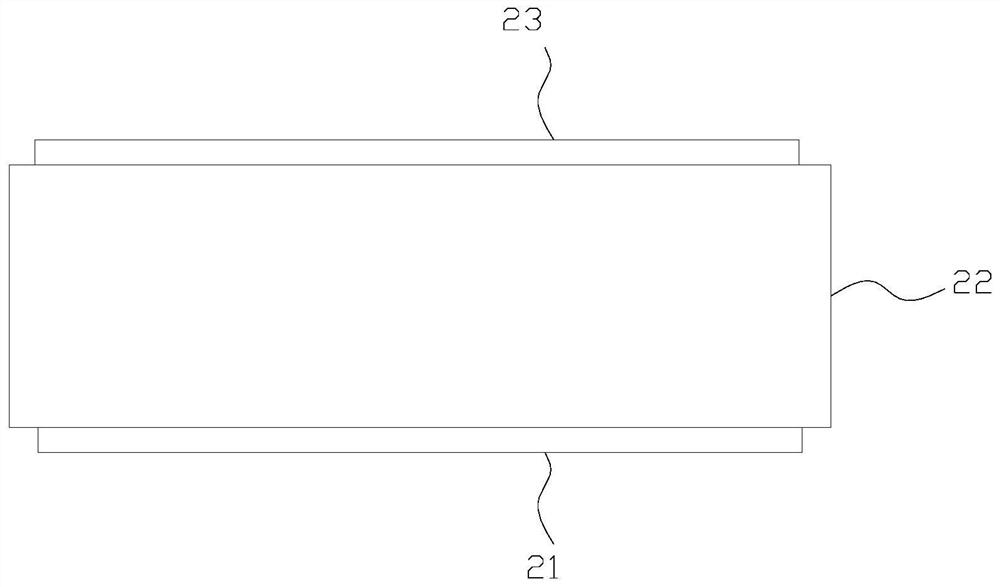

[0048] Such as Figure 5 As shown, the circuit board 1 is provided with a metallized hole 11 for the feed pin 6 of the ceramic antenna 2 to pass through, and the circuit board 1 is provided with a pad structure on the bottom surface opposite to the installation surface of the ceramic antenna 2. The pad structure is electrically connected, and connectors are also arranged on the side where the pad structure is located. In order to adapt to the above-mentioned method 1 and method 2, the metallized hole corresponding to the feed pin 6 of the bottom ceramic antenna 2 can be set as an arc structure on the circuit board 1, thereby increasing the versatility of the circuit board 1 and making stacking The ceramic antennas 2 can be directly rotated on the circuit board 1 of the same type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com