Gas mixing for fast temperature control of a cooling hood

A mixer and controller technology, applied in the field of gas mixing for rapid temperature control of the cooling cover, can solve the problem of reducing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

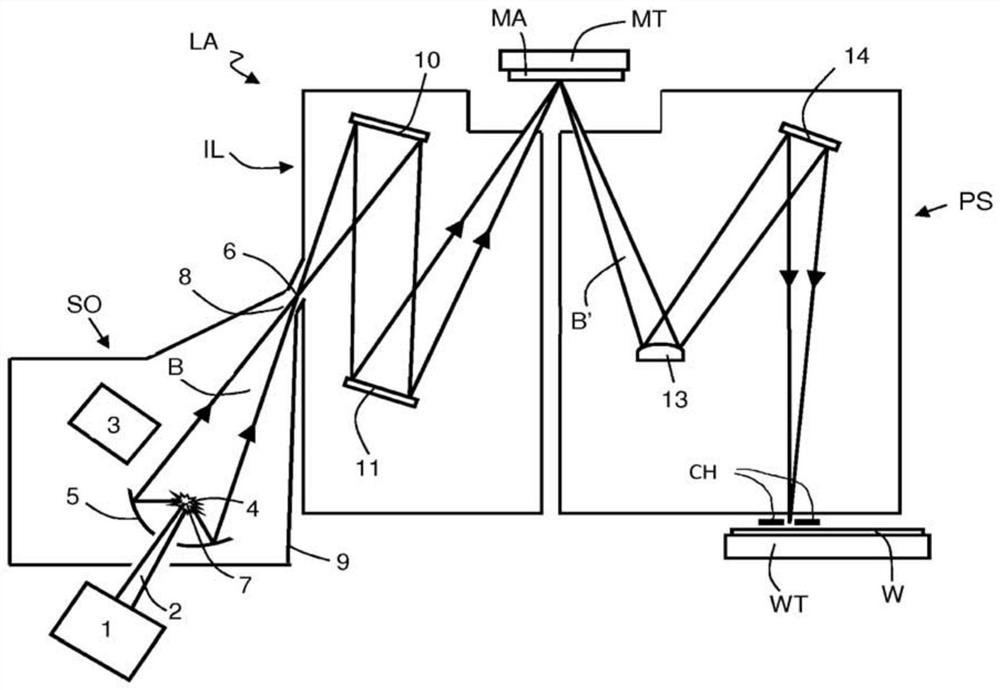

[0074] figure 1 A lithographic system comprising a radiation source SO and a lithographic apparatus LA is shown. The radiation source SO is configured to generate a beam B of EUV radiation and to provide the beam B of EUV radiation to the lithographic apparatus LA. The lithographic apparatus LA comprises an illumination system IL, a support structure MT configured to support a patterning device MA (eg a mask), a projection system PS and a substrate table WT configured to support a substrate W.

[0075] The illumination system IL is configured to condition the EUV radiation beam B before it is incident on the patterning device MA. Wherein, the illumination system IL may include a faceted field mirror device 10 and a faceted pupil mirror device 11 . The facet field mirror arrangement 10 and the facet pupil mirror arrangement 11 together provide the EUV radiation beam B with a desired cross-sectional shape and a desired intensity distribution. The illumination system IL may co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com