Air pressure removing device, system and method for waste cigarettes

A technology for removing devices and air pressure, which is applied in the fields of application, tobacco, and paper cigarette manufacturing, and can solve problems such as inconvenient maintenance, large equipment occupation, and leakage screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

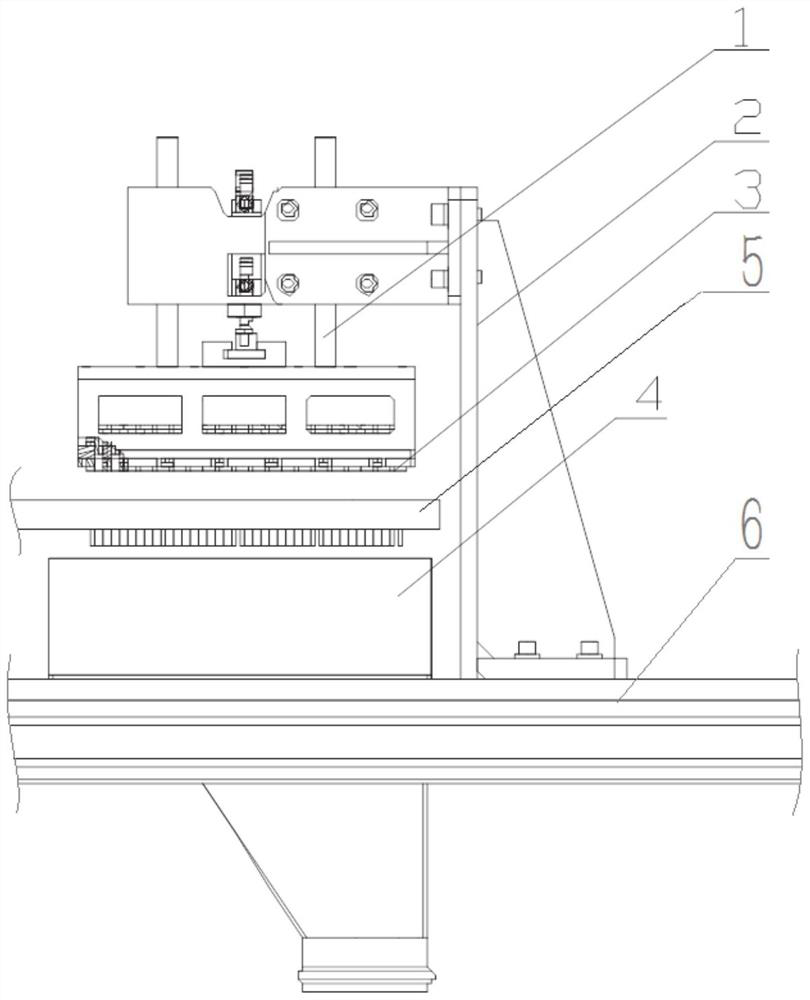

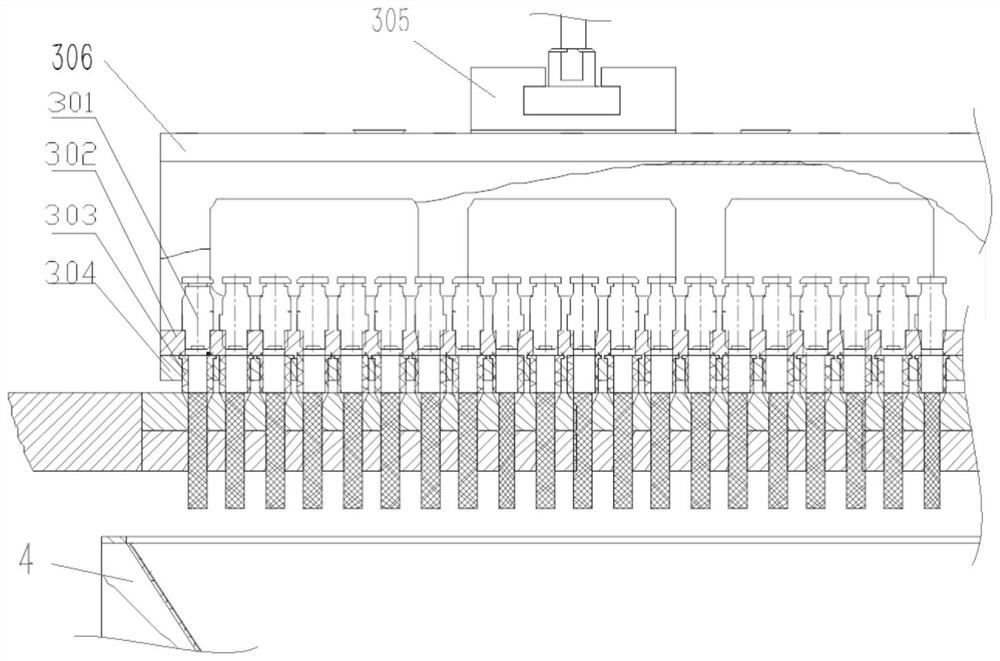

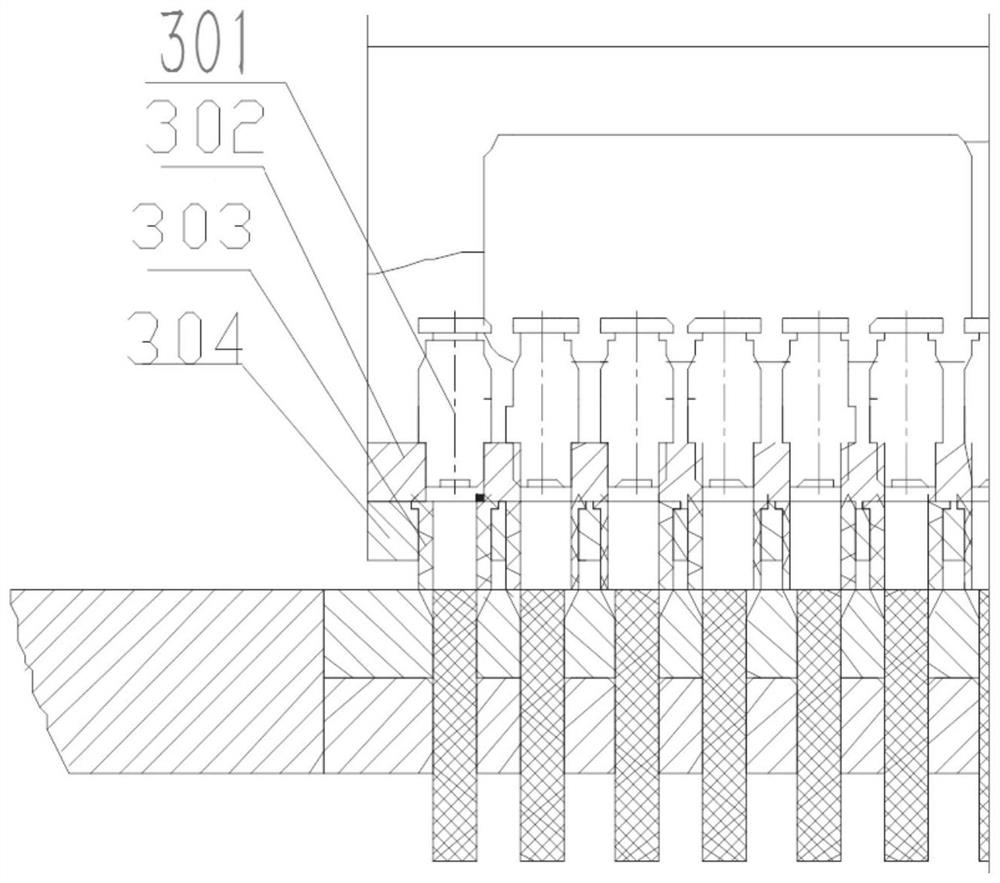

[0035] Such as Figure 1-Figure 3 As shown, this embodiment provides an air pressure rejecting device for waste cigarettes, which includes a plurality of flexible air nozzles 303 arranged in an array along a set plane and whose central axes are parallel to each other. The flexible air nozzles 303 are supported by the support structure 3, and the flexible air nozzles There is an air passage in 303, one end of the air passage communicates with the air supply mechanism, and the other end can be sealed and communicated with the suitable station hole in the cigarette mold box 5, the central axis of the flexible air nozzle 303 and the central axis of the station hole parallel;

[0036] The support structure 3 is connected to the linear drive mechanism 1, the driving direction of the linear drive mechanism 1 coincides with the central axis direction of the station hole, and the linear drive mechanism 1 can drive multiple flexible air nozzles 303 to complete the matching station hole ...

Embodiment 2

[0049] This embodiment provides an air pressure rejecting system for waste cigarettes, including the air pressure reject device for waste cigarettes, and also includes:

[0050] An image acquisition unit, the image acquisition unit can take images of cigarettes in the cigarette mold box 5 and the station hole;

[0051] The image analysis unit, the image processing unit can obtain the image transmitted by the image acquisition unit, and analyze whether the cigarettes in the station hole meet the filling requirements;

[0052] A control unit, the control unit can obtain the analysis result of the image analysis unit, control the action of the linear drive mechanism 1 and independently control the air supply of the flexible air nozzle 303 at different station holes.

[0053] It also includes a transfer mechanism, which is used to realize the transfer of the cigarette mold box 5 between the filling station and the cigarette removal station.

Embodiment 3

[0055] This embodiment provides a method for removing air pressure for waste cigarettes, which uses the air pressure removal system for waste cigarettes, and includes the following steps:

[0056] Use the image recognition unit and the image analysis unit to complete the identification of unqualified cigarettes filled in the cigarette mold box 5;

[0057] Transfer the cigarette mold box 5 between the waste chute and the flexible air nozzle 303, aligning the flexible air nozzle 303 with the corresponding station hole;

[0058] The linear drive mechanism 1 drives the flexible air nozzle 303 to press down, so that the lower ends of the flexible air nozzle 303 are respectively in sealing communication with the aligned station holes;

[0059] The control unit controls the air supply to the flexible air nozzle 303 connected to the station hole where the cigarette needs to be removed, and the gas in the flexible air nozzle 303 blows the unqualified cigarettes in the station hole out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com