Metal pipeline welding device

A welding device and metal pipeline technology, applied in welding equipment, metal processing, welding equipment, etc., can solve problems such as temperature rise and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

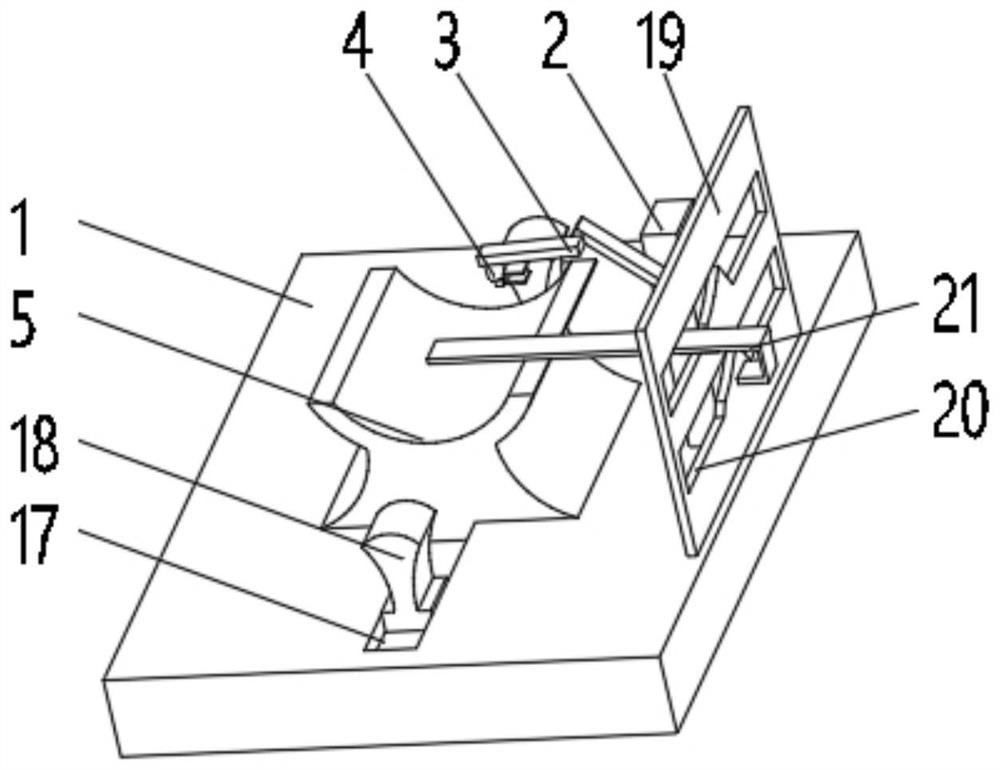

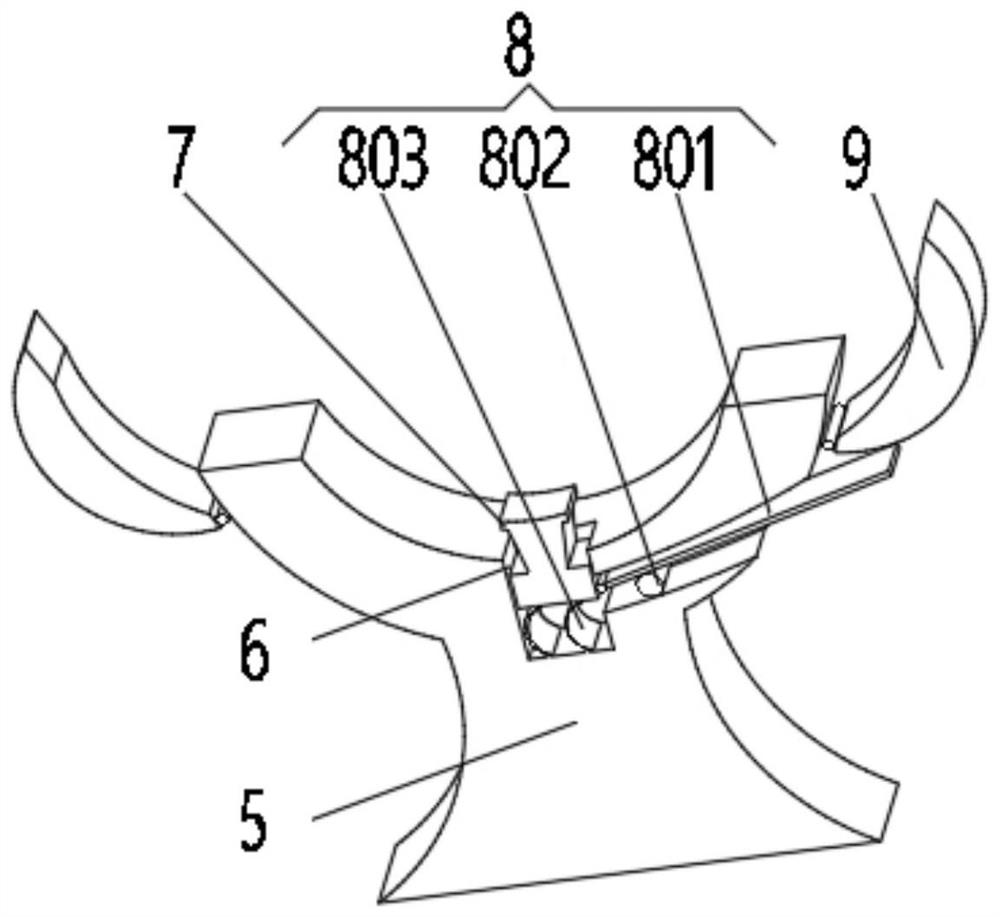

[0033] see Figure 1-2 , the present invention provides a technical solution: a metal pipe welding device, including a processing table 1, the top of the processing table 1 is fixedly connected with a support rod 2, and the top of the support rod 2 is connected with a welding head 4 through a deflection connecting rod 3, and the processing The middle position of the top of the table 1 is fixedly connected with the welding base 5, and the top of the welding base 5 is uniformly provided with a trigger groove 6, one side of the trigger groove 6 runs through the welding base 5, and a lifting block is slidingly connected between the two sides of the inner wall of the trigger groove 6 7. A trigger device 8 is installed on one side of the lifting block 7 inside the trigger groove 6, and a clamping device 9 is installed on both sides of the welding base 5, and the clamping device 9 is connected to the trigger device 8.

[0034] The trigger device 8 includes a seesaw 801, which is rota...

Embodiment 2

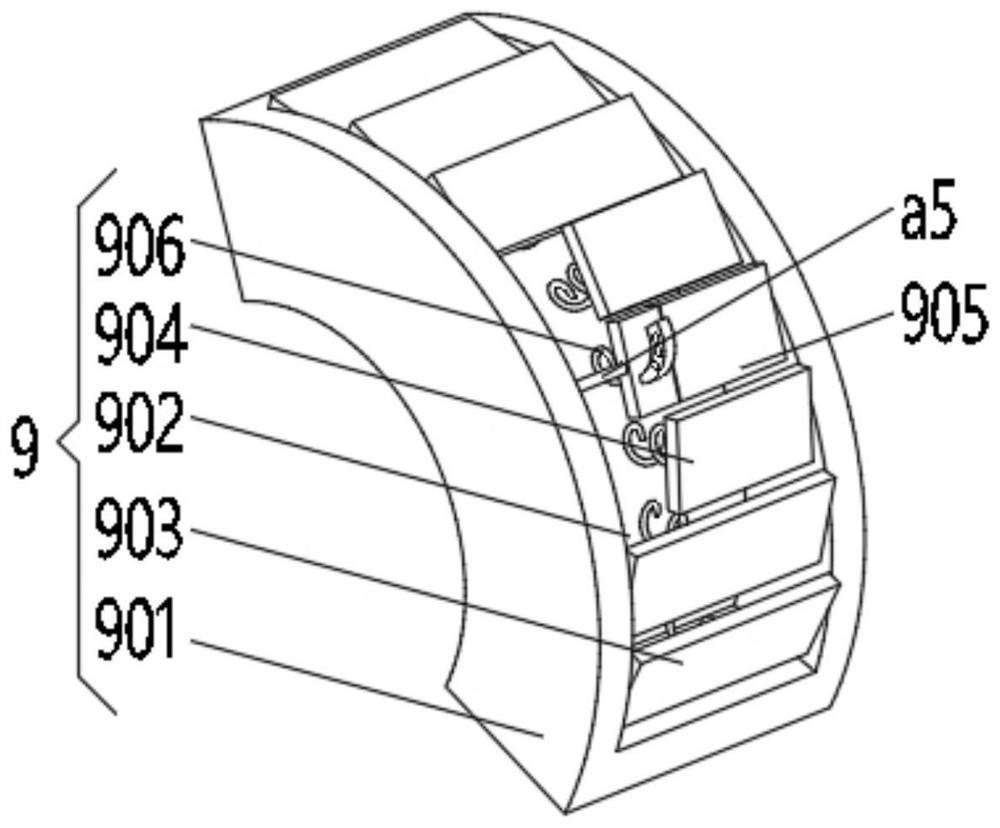

[0039]see Figure 1-4 , the present invention provides a technical solution: on the basis of Embodiment 1, the clamping device 9 includes a rubber clamp 901, and the side of the rubber clamp 901 away from the lifting block 7 is provided with an extrusion groove 902, and the extrusion groove 902 An extruding plate 903, a limiting plate 904 and a control plate 905 are installed between the two sides of the inner wall, and the extruding plate 903, the limiting plate 904 and the control plate 905 are all rotatably connected with the inner wall of the extruding groove 902, and the extruding groove 902 Squeeze springs 906 are evenly installed on one side of the inner wall.

[0040] The control board 905 includes a hard board a1, one side of the hard board a1 is fixedly connected with an elastic coil a2, the bottom of the elastic coil a2 is fixedly connected with a counterweight a4 through a traction rope a3, and one side of the inner wall of the extrusion groove 902 Rotationally co...

Embodiment 3

[0044] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 1, a funnel hole 10 is evenly opened on the bottom of the lifting block 7, and an atomization device 11 is installed inside the funnel hole 10, and the inside of the trigger groove 6 is located in the lifting block 7 The bottom of the slapping fan blade 111 is filled with cooling liquid, and the atomizing device 11 includes a flapping fan blade 111, which is evenly installed inside the funnel hole 10, and the outer side of the flapping fan blade 111 is provided with a mounting ring 112, and the mounting ring 112 and the The inner wall of the funnel hole 10 is slidably connected, and the top of the flapping fan blade 111 is provided with an atomizing hole 113 , and an atomizing plate 114 is evenly installed inside the atomizing hole 113 .

[0045] The bottom of the atomizing plate 114 is uniformly provided with magnet slots 12 , and both sides of the magnet slot 12 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com