Developing waste liquid treatment system

A technology of waste liquid treatment system and treatment pool, which is applied in natural water treatment, special treatment targets, water/sewage treatment, etc., and can solve problems such as low efficiency and large amount of waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-6 The application is described in further detail SS.

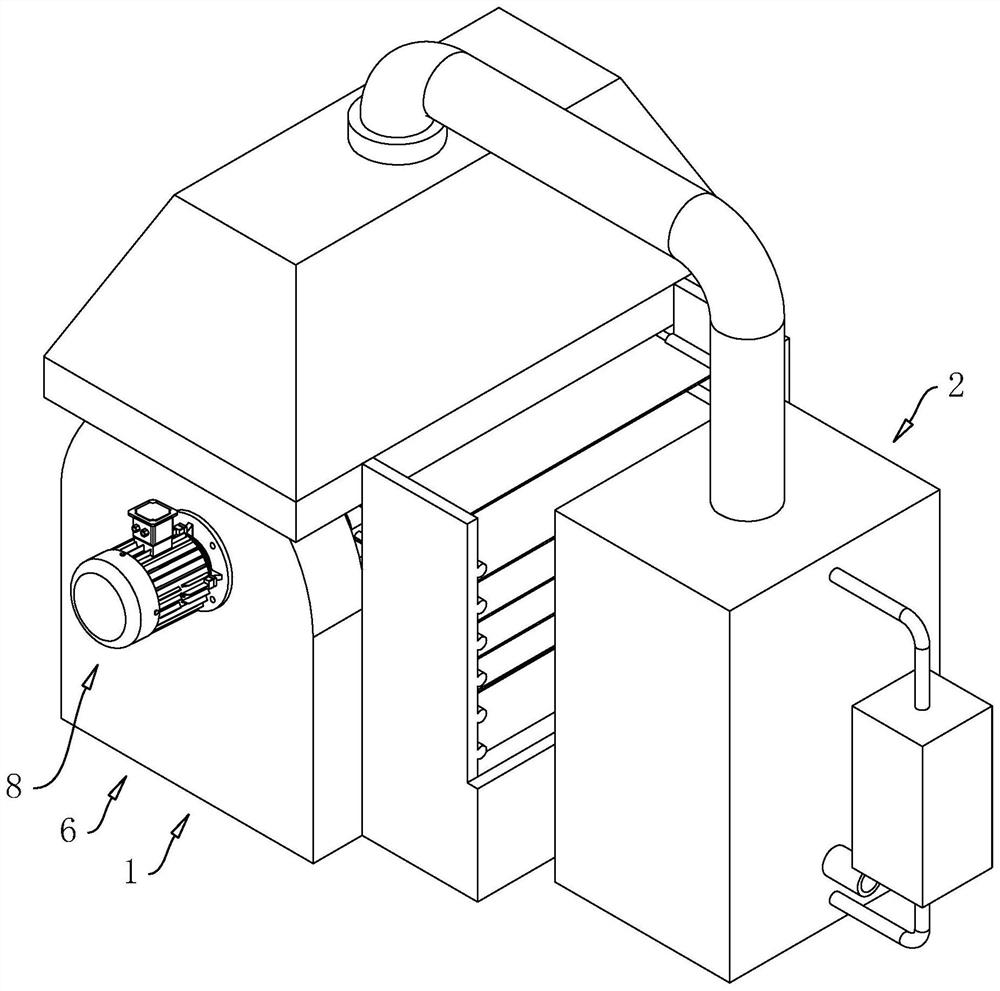

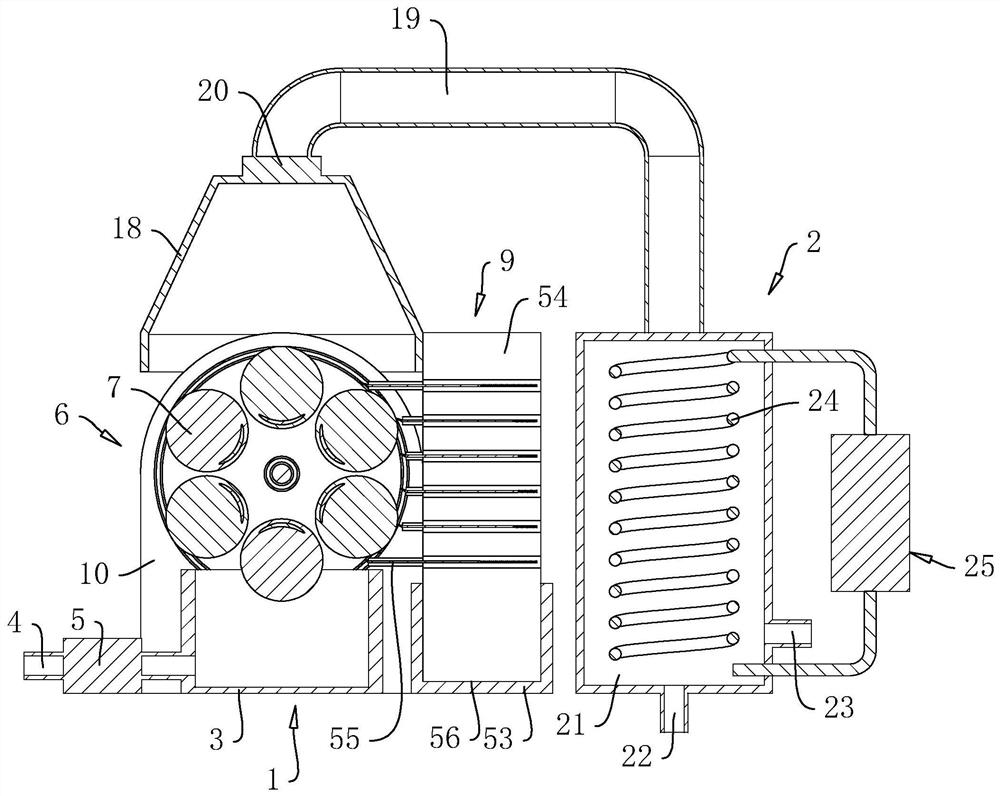

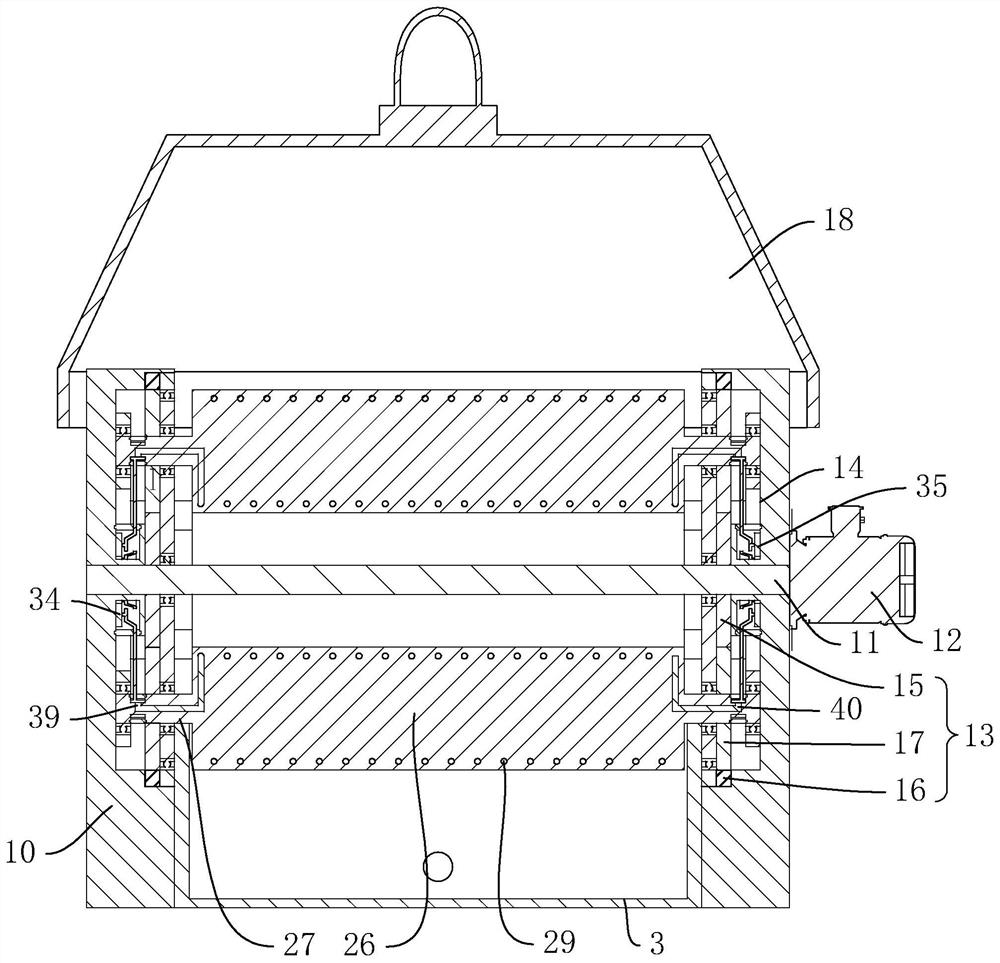

[0038] The embodiment of the present application discloses a developing waste liquid treatment system. refer to figure 1 and figure 2 , a developing waste liquid treatment system includes a heating and curing device 1 and a steam condensing device 2, wherein the heating and curing device 1 includes a processing tank 3, a liquid inlet pipe 4, a liquid inlet pump 5, a frame body 6, a heating roller 7, and a driving mechanism 8 and a scraping mechanism 9, the liquid inlet pipe 4 is connected to the position near the bottom of the processing tank 3, the liquid inlet pump 5 is installed on the liquid inlet pipe 4, and is used to pump the developing waste liquid toward the processing tank 3, and the frame body 6 includes A pair of side plates 10 located on both sides of the treatment pool 3, the heating roller 7 is preferably set to six, and the six heating rollers 7 are circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com