Mining light concrete filling construction device

A lightweight concrete and construction device technology, applied in clay preparation devices, fillings, safety devices, etc., can solve problems such as poor support stability, inability to realize construction operations, and high investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

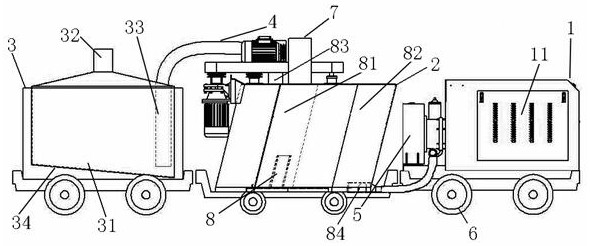

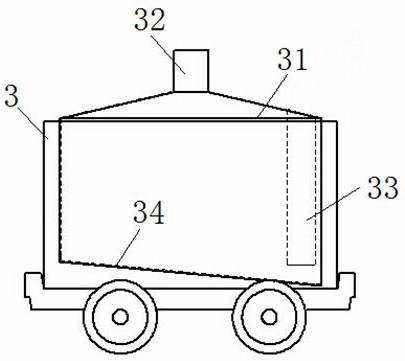

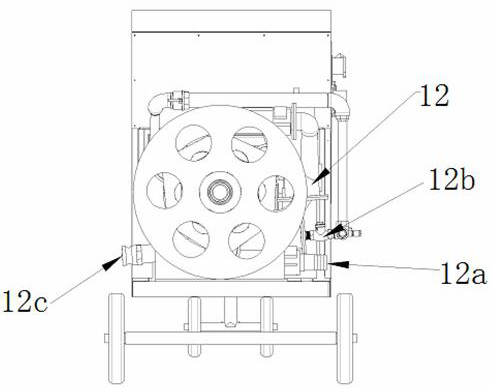

[0022] A mining lightweight concrete filling construction device, its main structure mainly includes a closed material turnover device 3 for carrying and conveying dry cement powder, a closed slurry making system 2 for mixing dry cement powder into cement slurry, and a The main control conveyor 1 is used to mix cement slurry with foam to generate foam concrete and output it to the outside. Wherein, the closed material turnover device 3 communicates with the closed pulping system 2 through a fully enclosed powder material lifting device 4, and the fully closed powder material lifting device 4 communicates with the closed material turnover device 3 through its feed pipeline, so The fully enclosed powder lifting device 4 communicates with the closed pulping system 2 through its discharge pipeline; the fully enclosed powder lifting device described in this embodiment adopts the existing conventional structure, and its function is to close the turnover device by power. The dry ceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com