Anodic automatic bonding equipment

An equipment and anode technology, applied in the field of bonding equipment in microelectronics technology, can solve the problems of insufficient functions of anode bonding technology equipment, and achieve the effects of high reliability, widening application scope and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings.

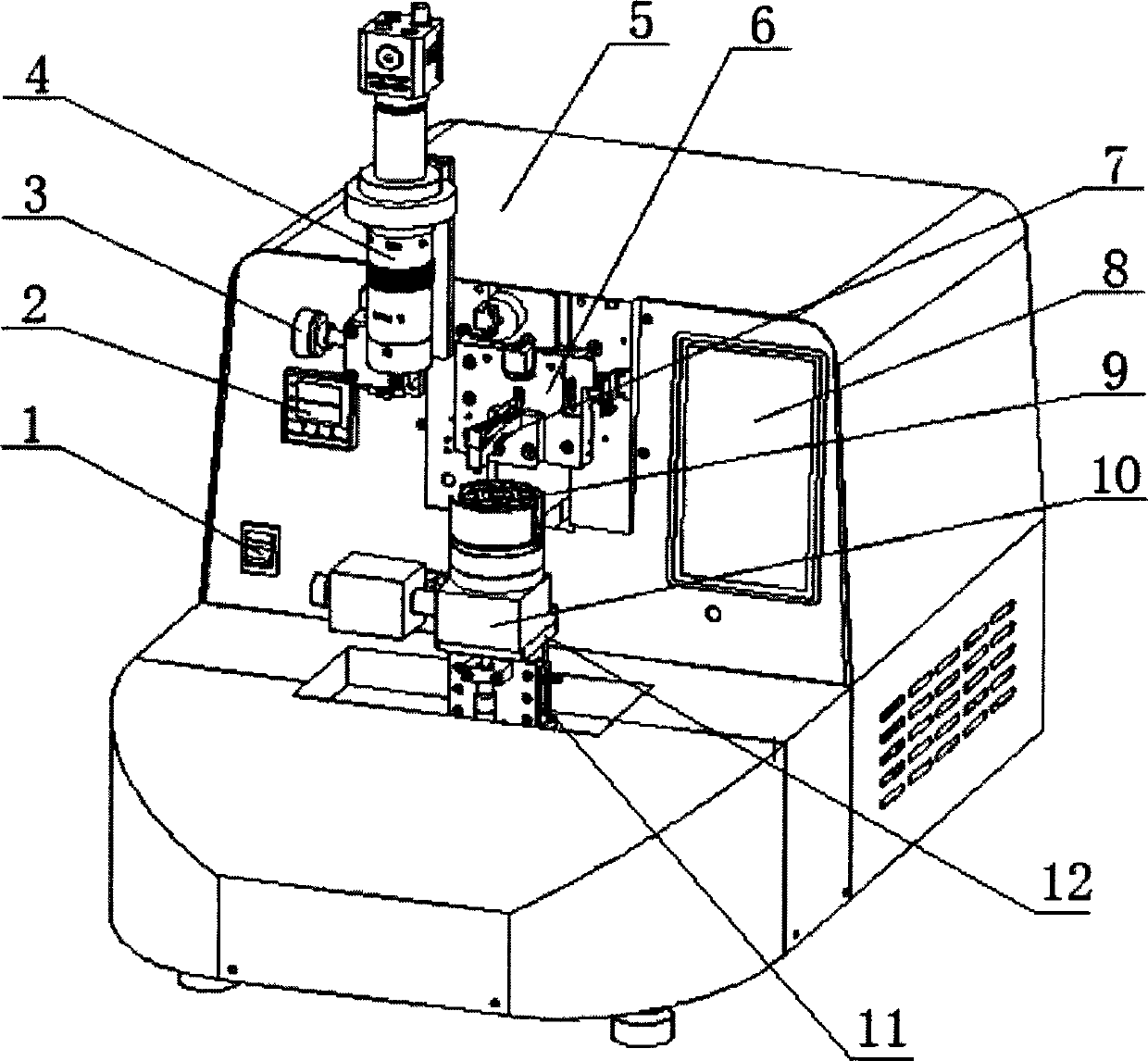

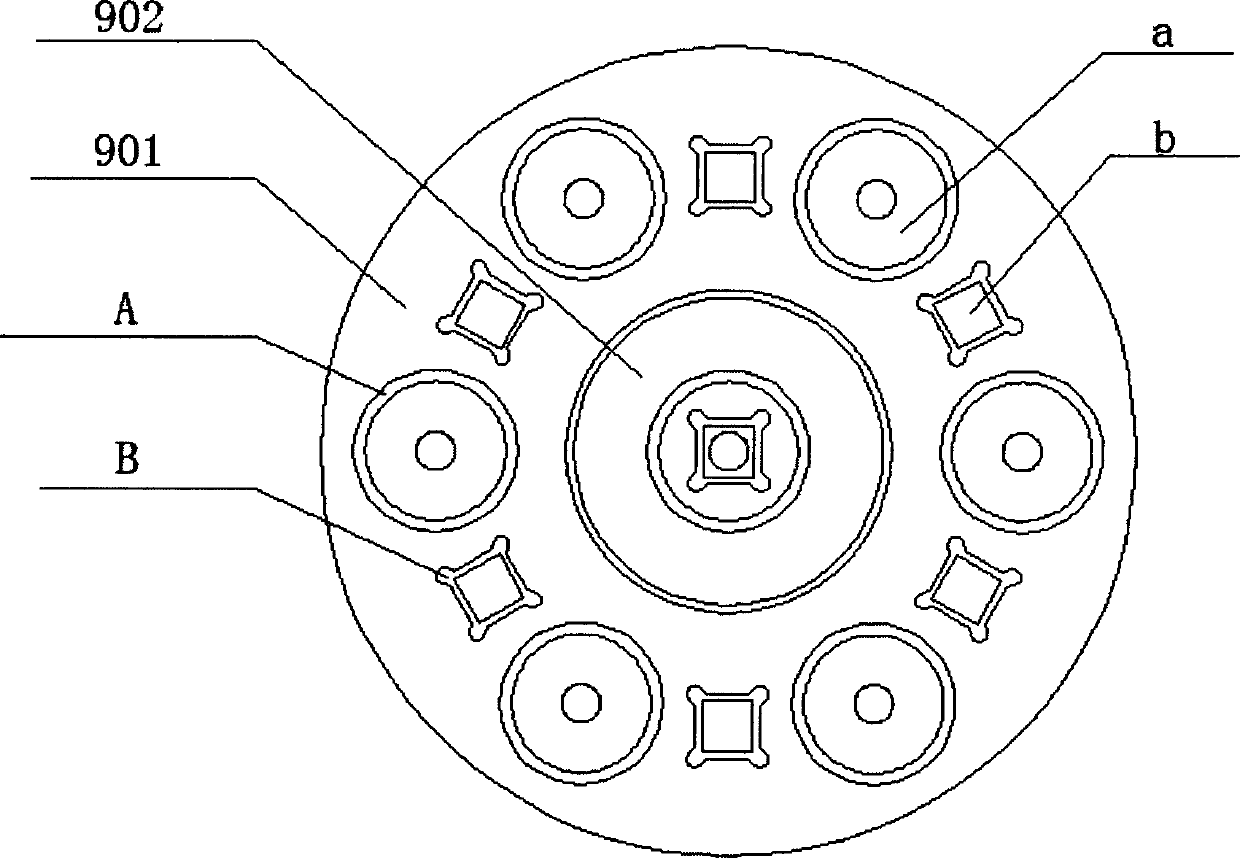

[0020] Such as figure 1 , Is a schematic diagram of the structure of the present invention, is an anode automatic bonding equipment, including a bonding treatment heating furnace 9, the upper part of which has a workpiece suction rod 7, the workpiece suction rod 7 is installed in the vertical movement of the lifting mechanism On 6, one side of the lifting and moving mechanism 6 is installed with a visual microscopy system 4 and an intelligent temperature adjustment table 3; a displacement rotating platform 10 is installed at the bottom of the bonding treatment heating furnace. The displacement rotary platform 10 moves through a rotary sliding table 11 installed at its bottom. The installation slot of the rotary sliding table is opened on the casing 5 of the anode automatic bonding equipment; a ceramic heat insulation sheet 12 is provided between the displacement rotary platform and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com