Double-piston-rod hydraulic oil cylinder

A hydraulic cylinder and double piston rod technology, applied in the field of hydraulic cylinders, can solve problems such as inconvenient installation, gear vibration, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

[0042] In the prior art, hydraulic motors and reduction boxes are usually used to generate adjustable torque, and the torque is converted into propulsion by sprockets and chains to solve the problem of the stability of the pressure bar under the action of its own propulsion in the single cylinder feed system. . However, the gear meshing process is noisy and prone to gear vibration, resulting in the stability of the pressure bar still exists.

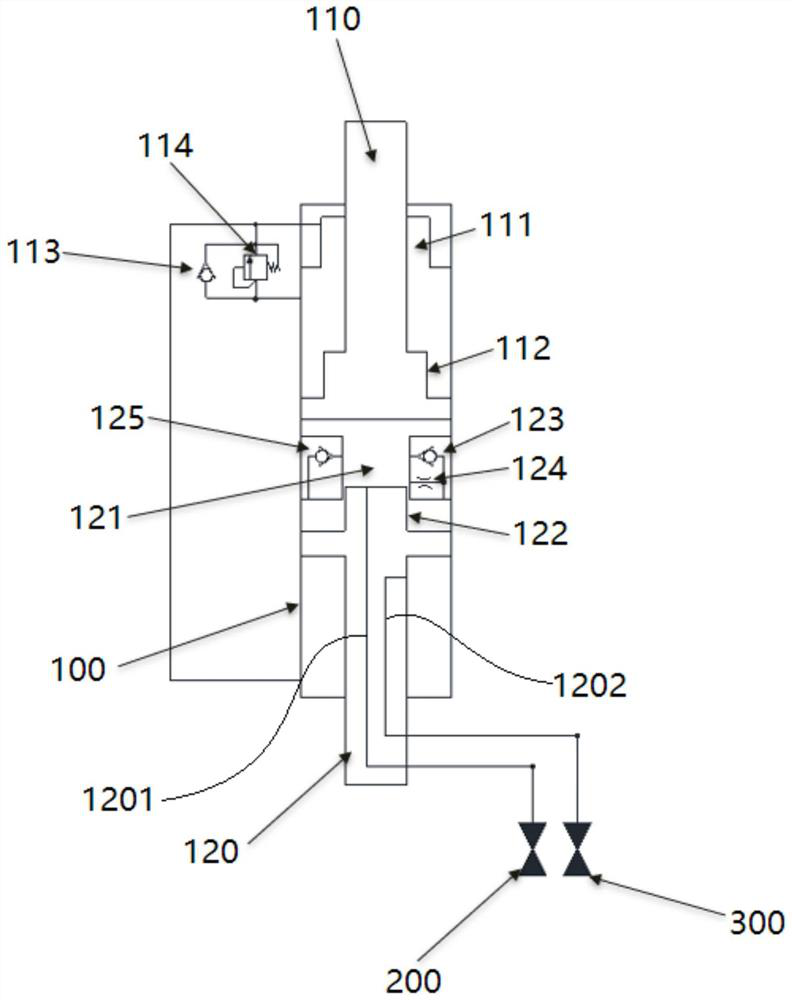

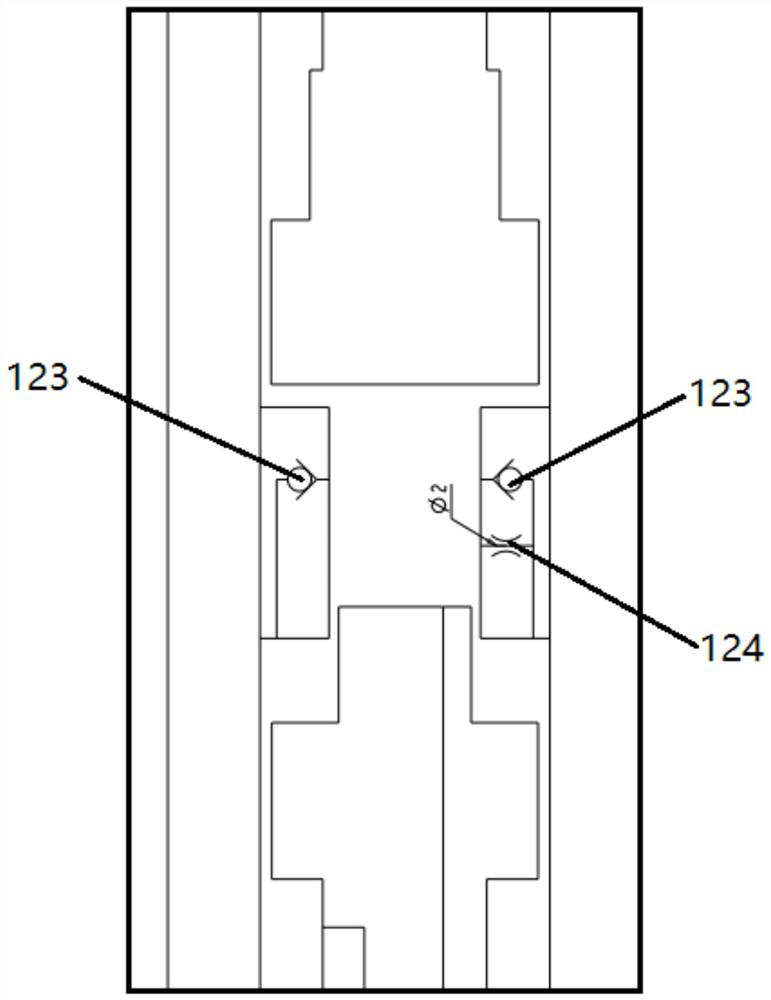

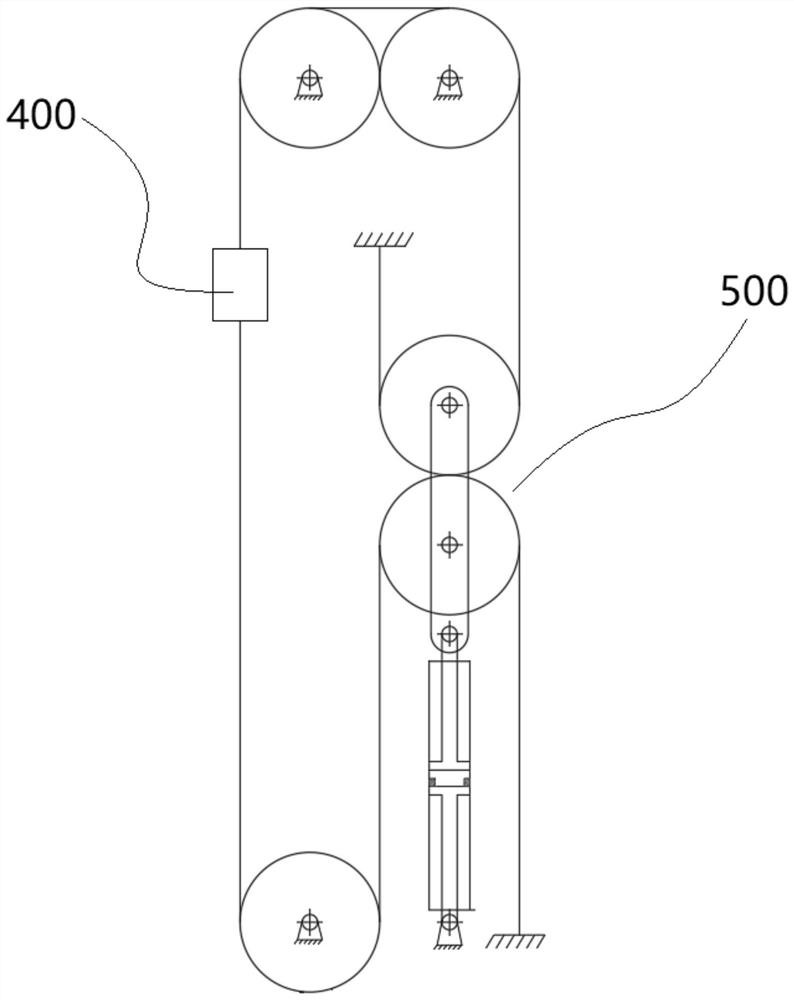

[0043] combine figure 1 with image 3 , the present invention provides a kind of double-piston rod hydraulic oil cylinder in order to solve the above-mentioned problem, and this hydraulic oil cylinder is used for driving movable pulley block 500 to pull power head 400 to move up and down, and drilling device is installed on power head 400; Specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com