Glass factory data analysis and intelligent prediction system

A data analysis and intelligent prediction technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve problems such as non-linear, high-order and time-delay systems that are not applicable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

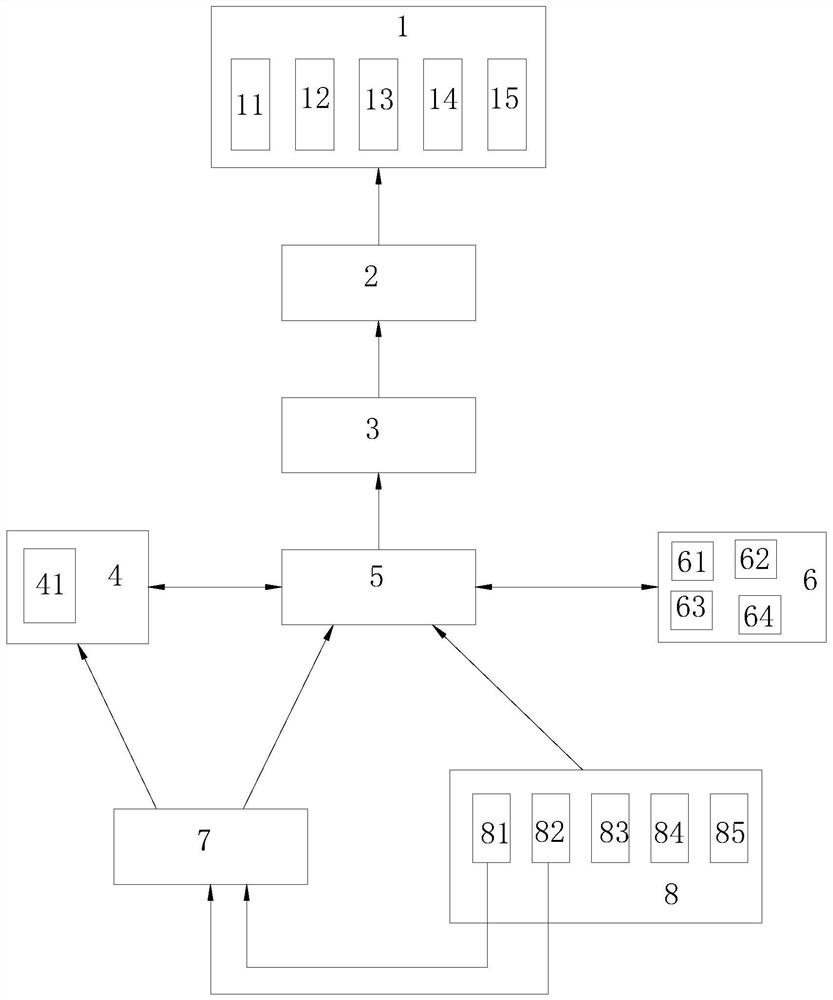

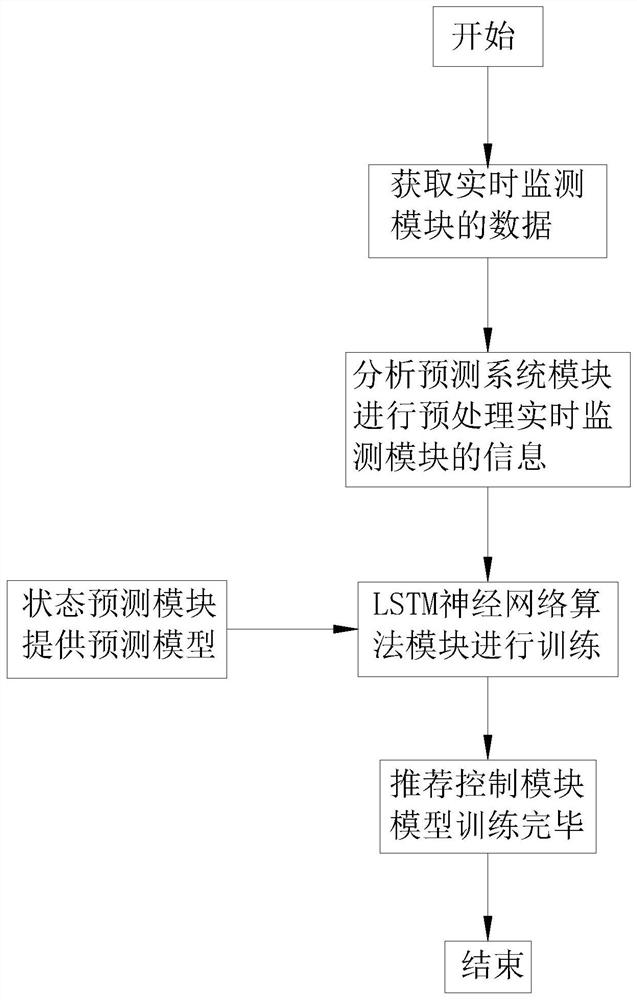

[0022] see Figure 1-Figure 2 As shown, the technical solution adopted in this specific embodiment is: it includes a display module 1, a forwarding station 2, an interface machine 3, a recommendation control module 4, an analysis and prediction system module 5, a data storage module 6, a state prediction module 7, real-time monitoring Module 8, the real-time monitoring module 8 is connected to the analysis and prediction system module 5 and the state prediction module 7, and the state prediction module 7 is connected to the recommendation control module 4 and the analysis and prediction system module 5, and the recommendation control module 4 and the analysis and prediction system module 5 are connected to each other, the analysis and prediction system module 5 and the data storage module 6 are connected to each other, the analysis and prediction system module 5 is provided with an interface machine 3, and the interface machine 3 is connected to the display module 1 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com