Packaging structure and packaging method of focal plane detector chip integrated pixel-level lens

A focal plane detector and packaging structure technology, which is applied in the direction of electric solid-state devices, semiconductor devices, sustainable manufacturing/processing, etc., can solve the problem that the window flat film does not have light convergence and collection, and reduces the detection signal-to-noise ratio of the focal plane chip. high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

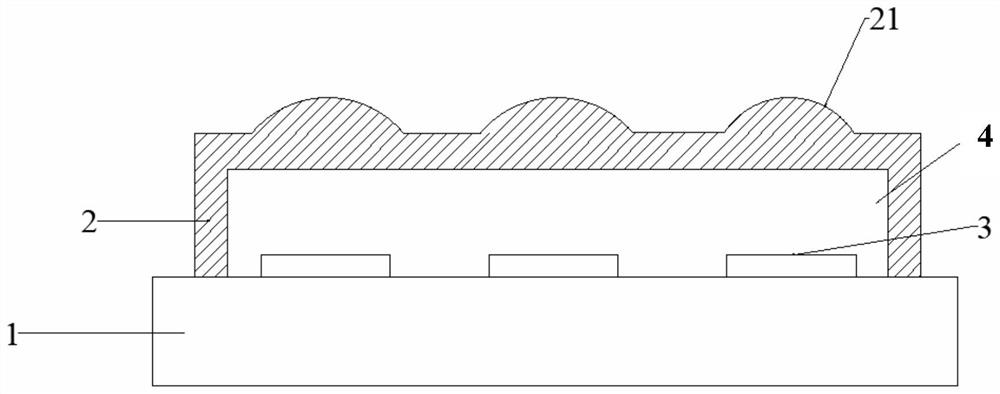

[0049] see figure 1 , a focal plane detector chip integrated pixel-level lens packaging structure, which includes a cooperating package cap 2 and a package base 1, the package cap 2 includes an integrally formed package cap body, a plurality of lenses 21 and an inner concave cavity 4; the plurality of lenses 21 are arranged in an array; the inner concave cavity 4 is used to seal and package a plurality of focal plane detector chips 3; the plurality of focal plane detector chips 3 are all arranged on the packaging base 1 , at the same time, the focus of a lens matched with a focal plane detector chip is distributed on the light-receiving surface of the focal plane detector chip.

Embodiment 2

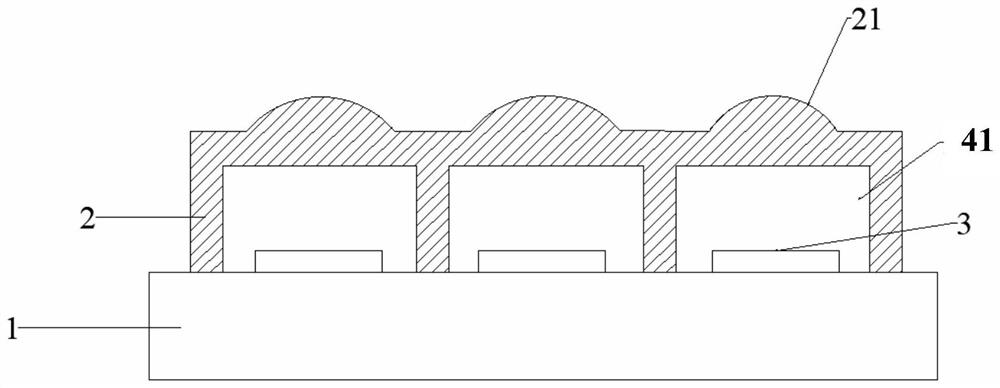

[0051] see figure 2 , a packaging structure of a focal plane detector chip integrated with a pixel-level lens, which includes a package cap 2 and a package base 1 that cooperate with each other, and the package cap 2 includes an integrally formed package cap body, a plurality of lenses 21 and a plurality of internal The concave cavity unit 41; the plurality of lenses 21 are arranged in an array, and are respectively arranged corresponding to the plurality of inner concave cavity units 41; the plurality of inner concave cavity units 41 are respectively used for sealing and packaging a plurality of focal plane detectors chip 3, and isolate the plurality of focal plane detector chips 3 from each other; the plurality of focal plane detector chips 3 are all arranged on the package base 1, and at the same time, a focal plane detector chip matched with a The focus of the lens is distributed on the light-receiving surface of the focal plane detector chip; one of the lenses 21 is inte...

Embodiment 3

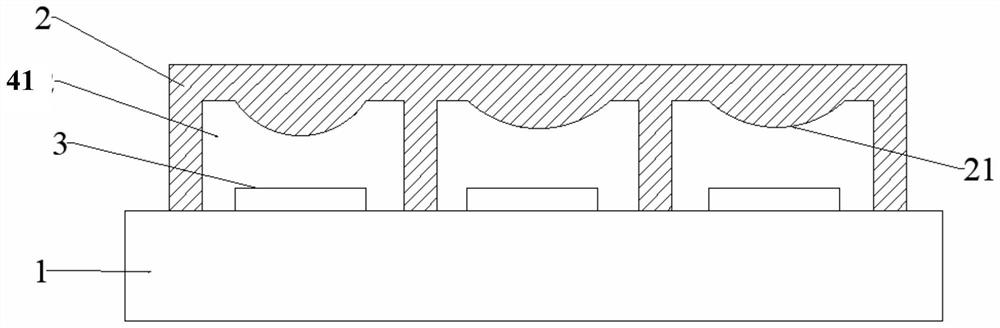

[0066] see image 3 , a packaging structure of a focal plane detector chip integrated with a pixel-level lens, which includes a package cap 2 and a package base 1 that cooperate with each other, and the package cap 2 includes an integrally formed package cap body, a plurality of lenses 21 and a plurality of internal The concave cavity unit 41; the plurality of lenses 21 are arranged in an array, and are respectively arranged corresponding to the plurality of inner concave cavity units 41; the plurality of inner concave cavity units 41 are respectively used for sealing and packaging a plurality of focal plane detectors chip 3, and isolate the plurality of focal plane detector chips 3 from each other; the plurality of focal plane detector chips 3 are all arranged on the package base 1, and at the same time, a focal plane detector chip matched with a The focus of the lens is distributed on the light-receiving surface of the focal plane detector chip; one of the lenses 21 is integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com