High-current connector

A technology of high-current connectors and current terminals, which is applied in the direction of connection, welding/welding connection, and parts of connection devices, etc., and can solve problems such as low current carrying, temperature rise, and unstable connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

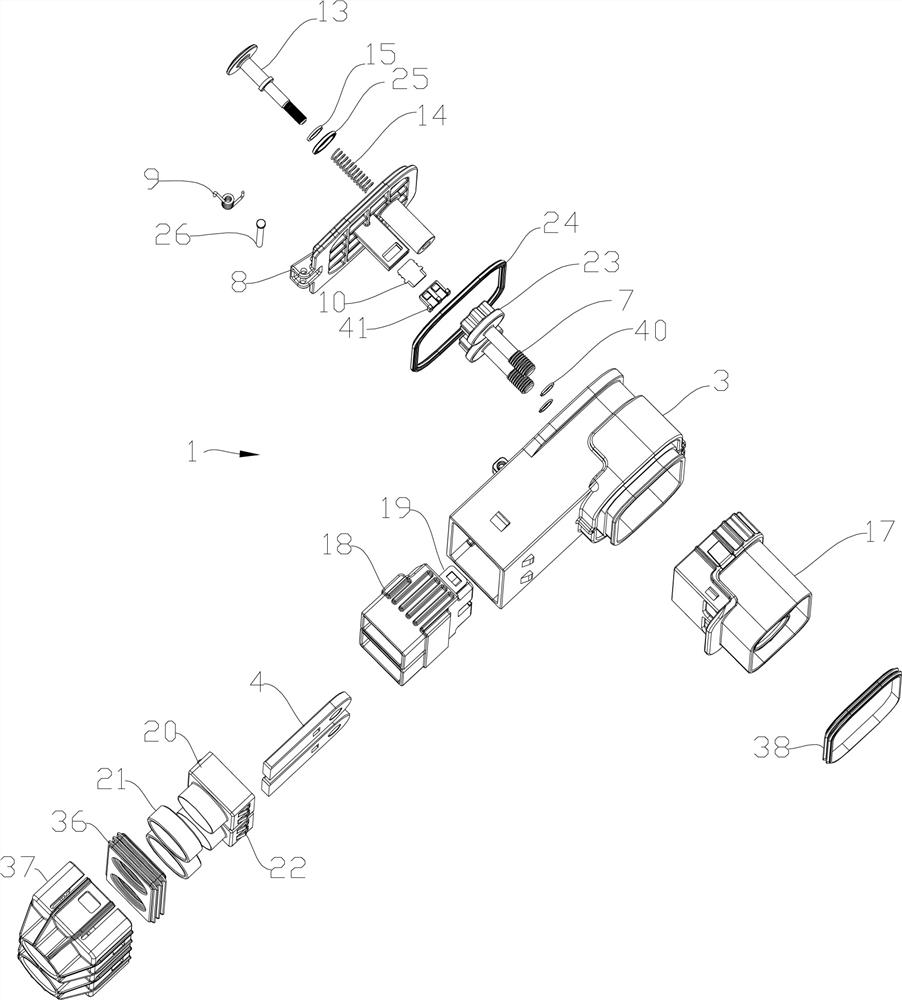

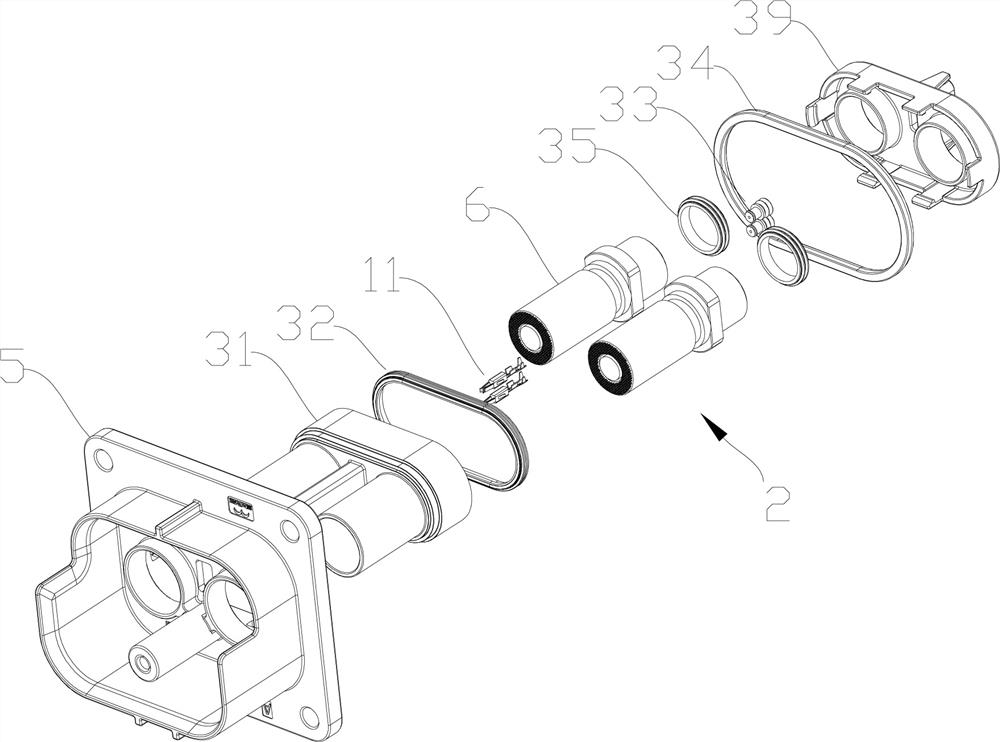

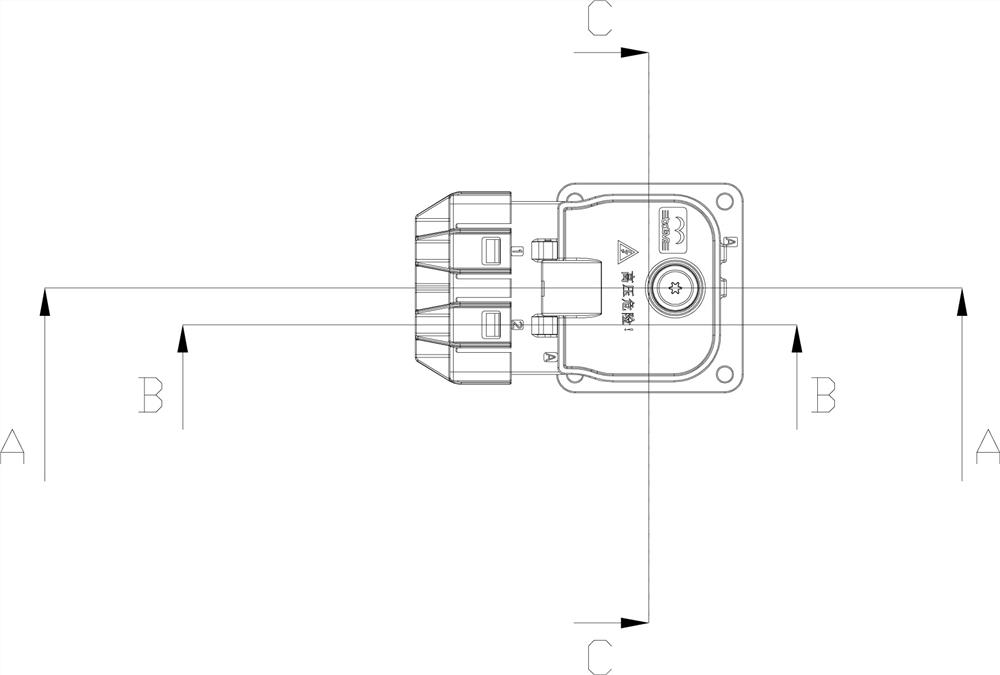

[0030] refer to Figure 1-10 As shown, the high-current connector of the present invention includes a plug 1 and a socket 2 that are plugged and mated. The plug 1 includes a plug housing 3 made of aluminum alloy material, and an adapter bar 4 arranged in the plug housing 3 . The socket 2 includes a socket housing 5 made of aluminum alloy material, and a current terminal 6 arranged in the socket housing 5 . After the plug 1 is plugged into the socket 2, the adapter bar 4 is connected to the current terminal 6 through the first locking screw 7 at the front end. The upper end of the plug housing 3 is hinged to an upper cover 8 via a latch 26, and a first spring 9 is provided at the hinge. The first spring 9 is a general term, and it may be a torsion spring, a shrapnel or the like. After the upper cover 8 is opened, the first locking screw 7 is installed from the upper end of the plug housing 3 to connect the adapter bar 4 and the current terminal 6 . The upper cover 8 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com