Permanent magnet type direct current motor driving device and electric equipment

A technology of DC motors and driving devices, applied in the direction of DC motor speed/torque control, conversion equipment without intermediate conversion to AC, output power conversion devices, etc., can solve the development constraints and influence of permanent magnet DC motors, and affect the economy Construction and national defense construction, difficult to deal with issues such as investigative technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

[0095] In the example, Figure 4 can also be Figure 11 Instead, a new device is formed, and other structures and descriptions are the same.

[0096] In Modification 1, the same reference numerals are assigned to the same configurations as those in the first embodiment, and the same descriptions will be omitted.

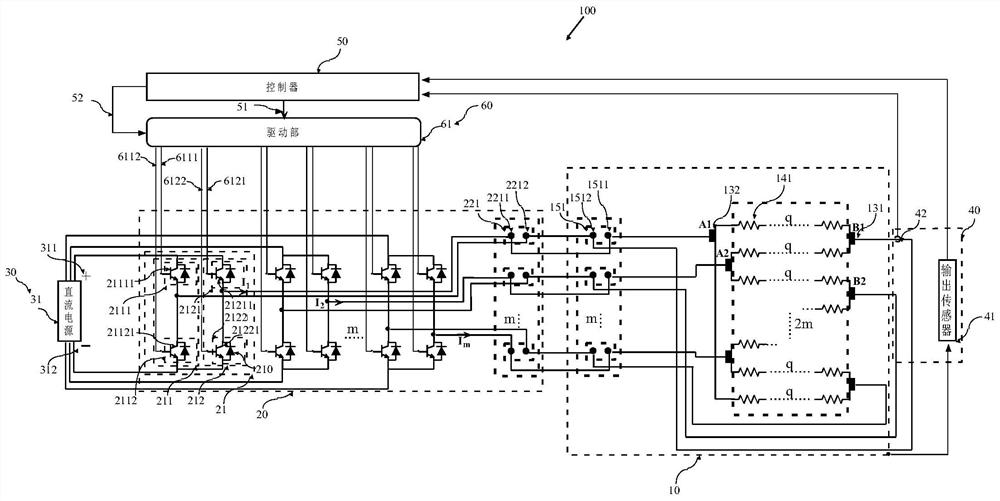

[0097] Figure 11 It is a schematic diagram of the circuit connection of the transverse section of the permanent magnet DC motor in Modification 11 of the present invention.

[0098] Such as Figure 11 As shown, the permanent magnet DC motor 10 in Modification 1 of the present invention also includes a field winding part 122, and the field winding part contains m field winding units, and m is an integer not less than 2. In this Modification 1, m is set to 3 .

[0099] The stator 12 includes three pairs of six main magnetic poles 121 and one field winding portion 122 . Each main magnetic pole 121 includes three excitation coils 12211, and each excitation coil 12...

Deformed example 2

[0106] In the example, Figure 4 can also be Figure 12 Instead, a new device is formed, and other structures and descriptions are the same.

[0107] In this modification 2, the same reference numerals are assigned to the same configurations as those in the first embodiment and the modification 1, and the same descriptions are omitted.

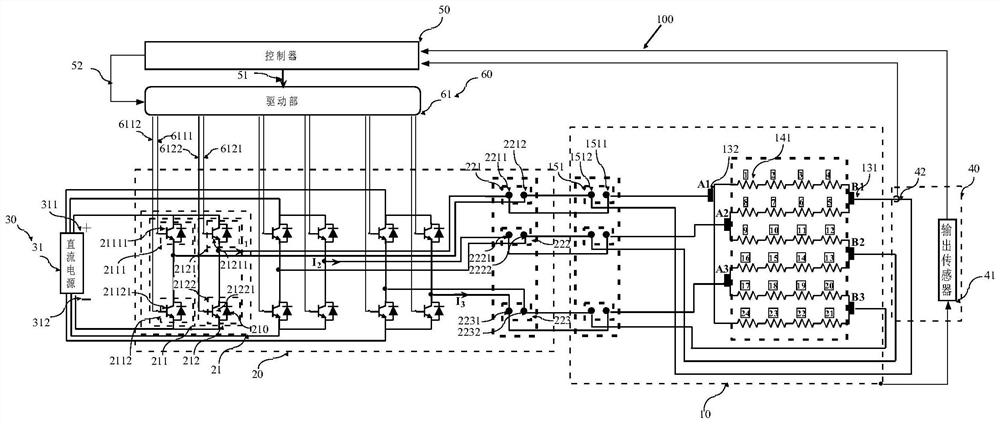

[0108] Figure 12 It is a schematic diagram of the circuit connection of the transverse section of the permanent magnet DC motor in Modification 2 of the present invention.

[0109] The field winding unit 122 includes m field winding units 1221 , and the m field winding units 1221 correspond to m pairs of main magnetic poles 121 respectively. Each excitation winding unit 1221 is formed by forming an excitation coil 12211 on a corresponding pair of main magnetic poles 121 with an insulated conductor strip made of a metal wire wrapped with an insulating layer.

[0110] Each pair of brushes 13 corresponds to the corresponding spatial position...

Deformed example 3

[0113] In the example, Figure 4 can also be Figure 13 Instead, a new device is formed, and other structures and descriptions are the same.

[0114] In the present modification 3, the same reference numerals are assigned to the same configurations as those in the first embodiment and the modification 1, and the same descriptions are omitted.

[0115] Figure 13 It is a schematic diagram of the circuit connection of the transverse section of the permanent magnet DC motor in Modification 3 of the present invention.

[0116] Such as Figure 13 As shown, the m one ends of the insulated conductor strips of all excitation winding units are electrically connected with the m N-pole corresponding brushes 132 in all brushes 13 to form m first terminals 1511, 1521 and 1531, and at the same time, all excitation windings The m other ends of the insulated conductor bar of the unit 1221 are electrically connected with the corresponding brushes 131 of m S poles in all brushes 13 to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com