Production method and equipment for reducing buprofezin impurities

A technology for thiazide and impurities, which is applied in the field of production methods and equipment for reducing thiazide impurities, can solve the problem of high impurity content of M291, and achieve the effects of improving yield, improving stirring stability and improving process methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

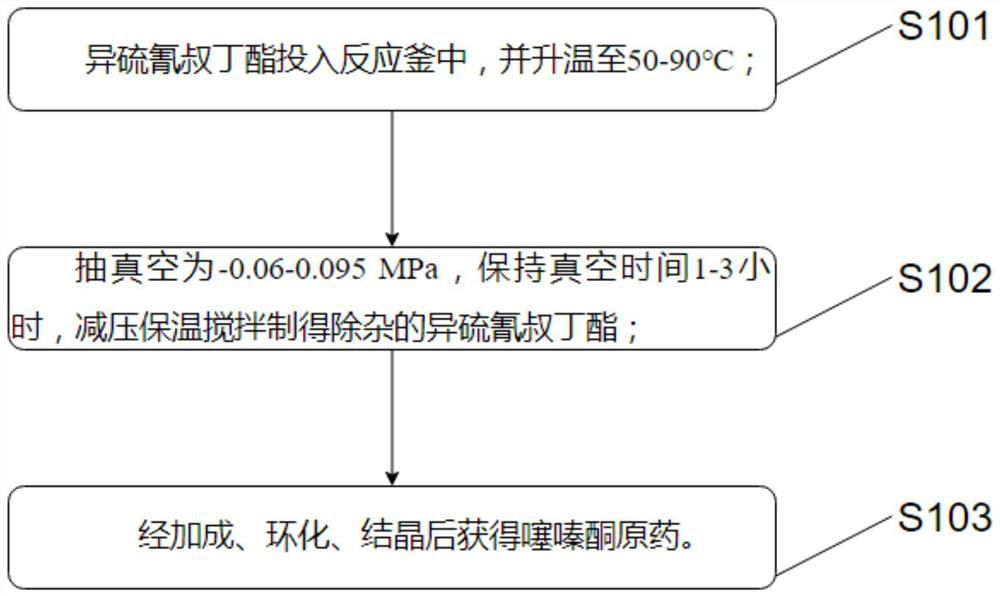

[0044] Put 115g (0.1mol) of tert-butyl isothiocyanate into the reaction kettle, raise the temperature to 50°C, increase the vacuum to -0.095Mpa, keep the vacuum stable, stir for 1 hour, and lose 0.5% of tert-butyl isothiocyanate;

[0045] Carbon disulfide in tert-butyl isothiocyanate was quantified by liquid chromatography, and the content was confirmed to be reduced to 0.08%;

[0046] The obtained tert-butyl isothiocyanate is added, cyclized and crystallized to obtain the original drug of buprofezin, and the content of M291 is 0.05%.

specific Embodiment 2

[0048] Put 115g (0.1mol) of tert-butyl isothiocyanate into the reaction kettle, raise the temperature to 70°C, increase the vacuum to -0.085Mpa, keep the vacuum stable, stir for 1 hour, and lose 0.5% of tert-butyl isothiocyanate;

[0049] Carbon disulfide in tert-butyl isothiocyanate was quantified by liquid chromatography, and the content was confirmed to be reduced to 0.03%;

[0050] The obtained tert-butyl isothiocyanate is added, cyclized and crystallized to obtain the original drug of buprofezin, and the content of M291 is 0.02%.

specific Embodiment 3

[0052] Put 115g (0.1mol) of tert-butyl isothiocyanate into the reaction kettle, raise the temperature to 80°C, increase the vacuum to -0.07Mpa, keep the vacuum stable, stir for 2 hours, the loss of tert-butyl isothiocyanate is 1.3%;

[0053] Carbon disulfide in tert-butyl isothiocyanate was quantified by liquid chromatography, and the content was confirmed to be reduced to 0.05%;

[0054] The obtained tert-butyl isothiocyanate is added, cyclized and crystallized to obtain the original drug of buprofezin, and the content of M291 is 0.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com