Intelligent welding real-time sensing and quality monitoring system based on 5G

A quality monitoring and intelligent technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of worker safety impact, welding process is difficult to ensure strict implementation, welding machine can not guarantee the quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

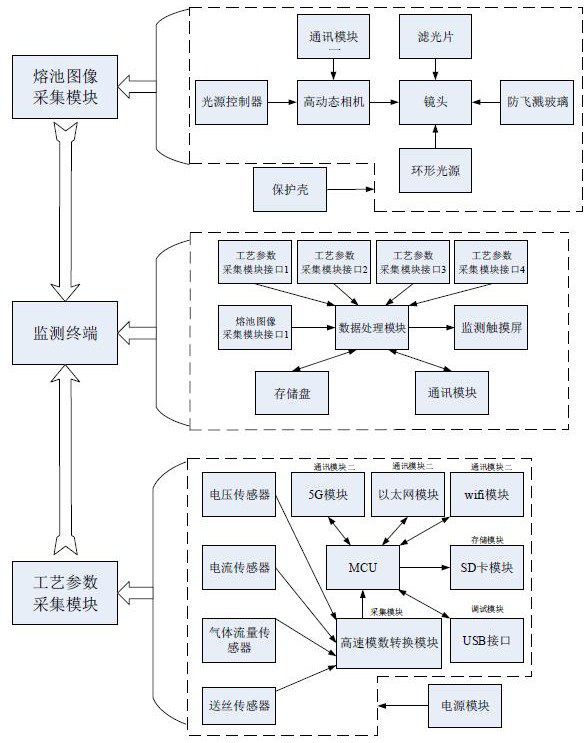

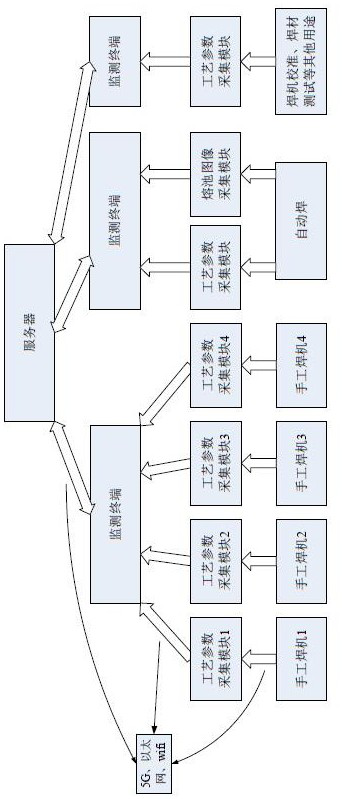

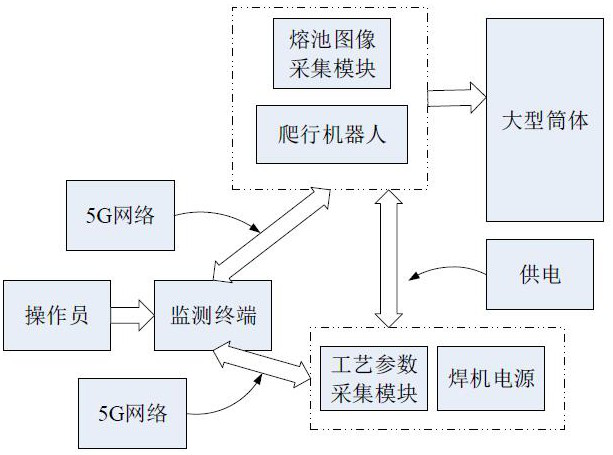

[0025] This embodiment provides a 5G-based intelligent welding real-time sensing and quality monitoring system, such as Figure 1-2 As shown, the present invention is applied in the management of workshop welding quality. Modular design is adopted, so the monitoring network can be flexibly established according to different welding methods and actual working conditions. For example, for manual welding machines, only process parameters are collected, while for automatic welding, a molten pool image acquisition module can be added. The terminal can be placed anywhere in the workshop for one-to-many monitoring, and upload historical data to the storage server in the office for long-term storage. The monitoring terminal can also retrieve data from any other station from the storage server for viewing and analysis. In addition, each module can be used independently for other purposes, for example, the process parameter acquisition module can be used for welding machine calibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com