Fixing chuck of plastic pipeline cutting machine

A technology for plastic pipes and fixed chucks, which is applied in mechanical equipment, metal processing, springs/shock absorbers, etc. It can solve problems such as cutting vibrations, affecting pipe dimensional accuracy and surface smoothness, and unstable fixing of tubular plastic parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

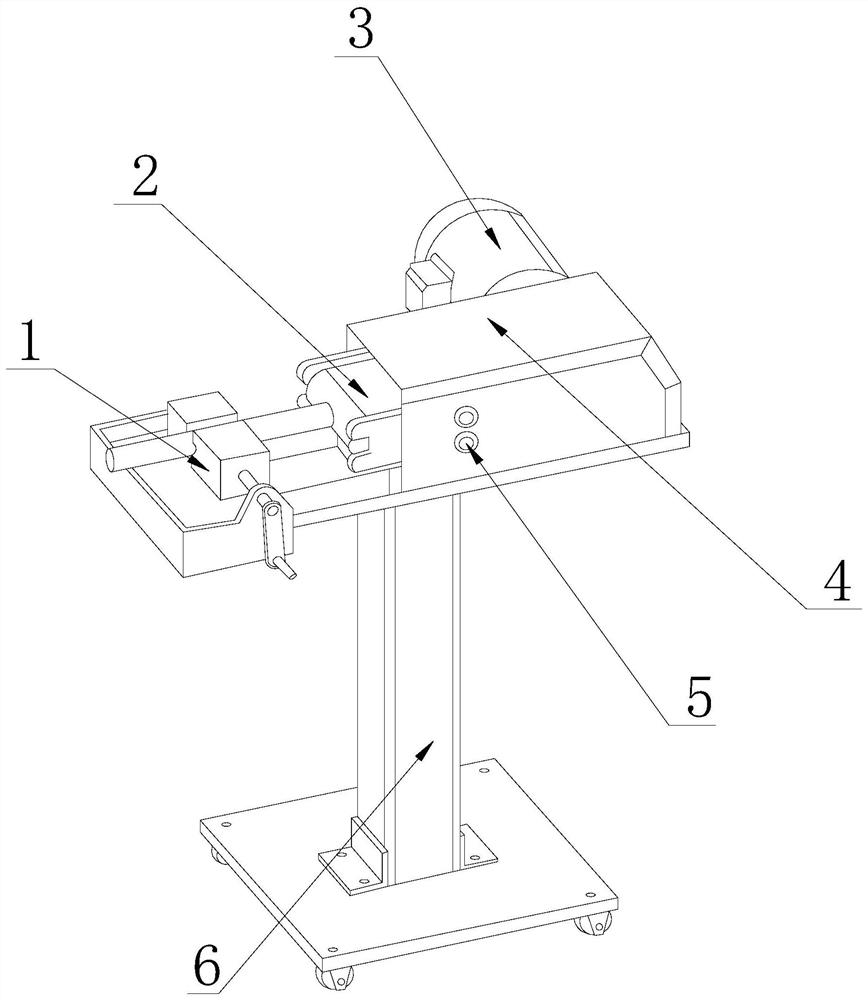

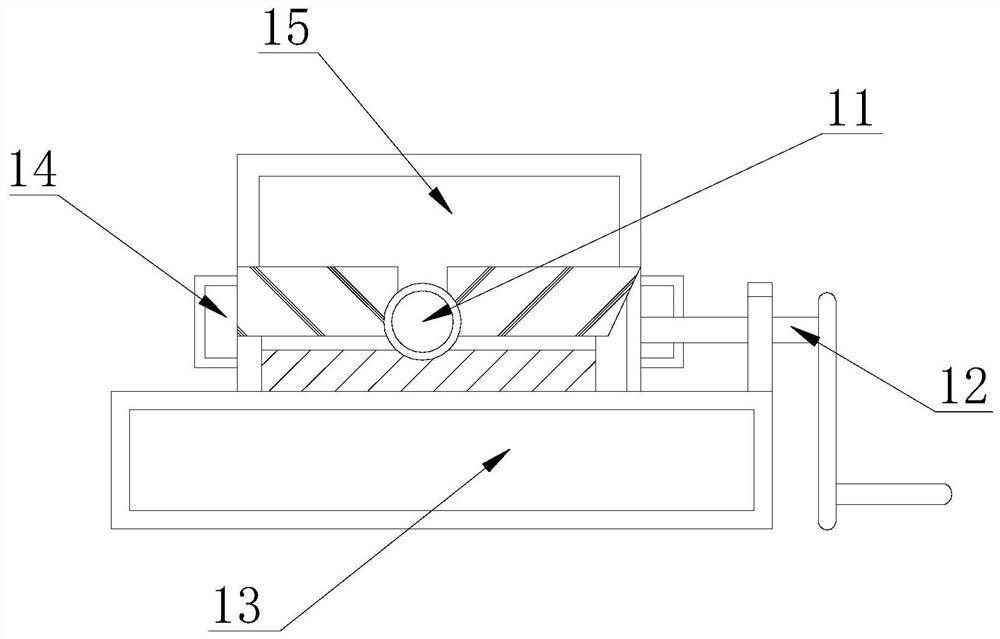

[0026] as attached figure 1 To attach Figure 5 Shown:

[0027] Its structure includes a fixing part 1, a cutting sleeve 2, a motor 3, a protective cover 4, a control button 5, and a support frame 6. 4 internal nesting fit, the left side of the protective cover 4 is fixed with the bolts of the motor 3, the motor 3 is movably matched with the cutting sleeve 2, the lower end of the cutting sleeve 2 is fixed with the surface bolts of the support frame 6, and the support The upper surface of the frame 6 is hingedly connected with the lower end of the protective cover 4, the surface of the protective cover 4 is nested with the control button 5, and the fixed part 1 includes a clamp 11, a crank handle 12, a carrier 13, a guard plate 14, and a pipe groove 15. The lower end of the clamp 11 is embedded and connected with the carrier 13, the upper end of the carrier 13 is fixed with the pipe groove 15 by bolts, the two sides of the pipe groove 15 are welded with the guard plate 14, an...

Embodiment 2

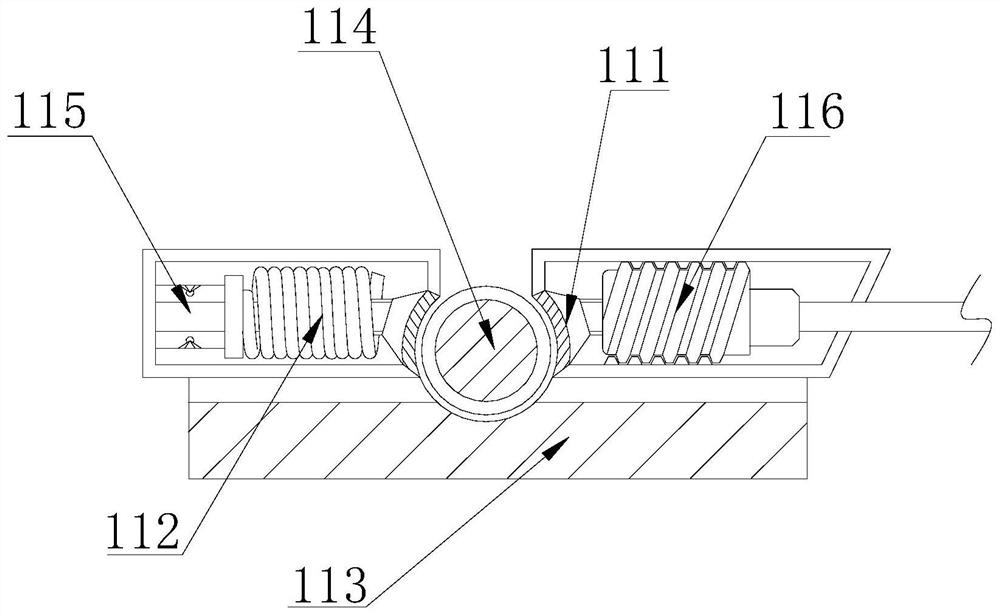

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the bearing platform 113 includes a pipe frame b1, a working chamber b2, a card slot b3, a pressure-reducing seat b4, and a guard plate b5. The lower end of the tube frame b1 is movably engaged with the card slot b3. Cooperate with the internal activities of the working chamber b2, the interior of the working chamber b2 is in clearance with the step-down seat b4, the top of the step-down seat b4 is in clearance with the guard plate b5, and the end of the guard plate b5 is movably engaged with the pipe frame b1, The pipe bracket b1 is distributed between the guard plates b5, engaged by the lower end slot b3, and restored by the internal spring after loss of pressure. The pipe bracket b1 is conducive to carrying the bottom while cutting the pipe, Effectively support the cutting force of its pipeline.

[0036] Wherein, the pressure-reducing seat b4 includes a fixed ring c1, a support rod c2, an air press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com