Diameter-adjustable double-screw plasticizing extruder for plastic modification process

An adjustable, twin-screw technology, used in the field of plasticizing extruders, can solve the problems of wasting raw materials, increasing the shear heat of small materials, and reducing physical properties, reducing energy loss, reducing rust blocking, and facilitating The effect of color change cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

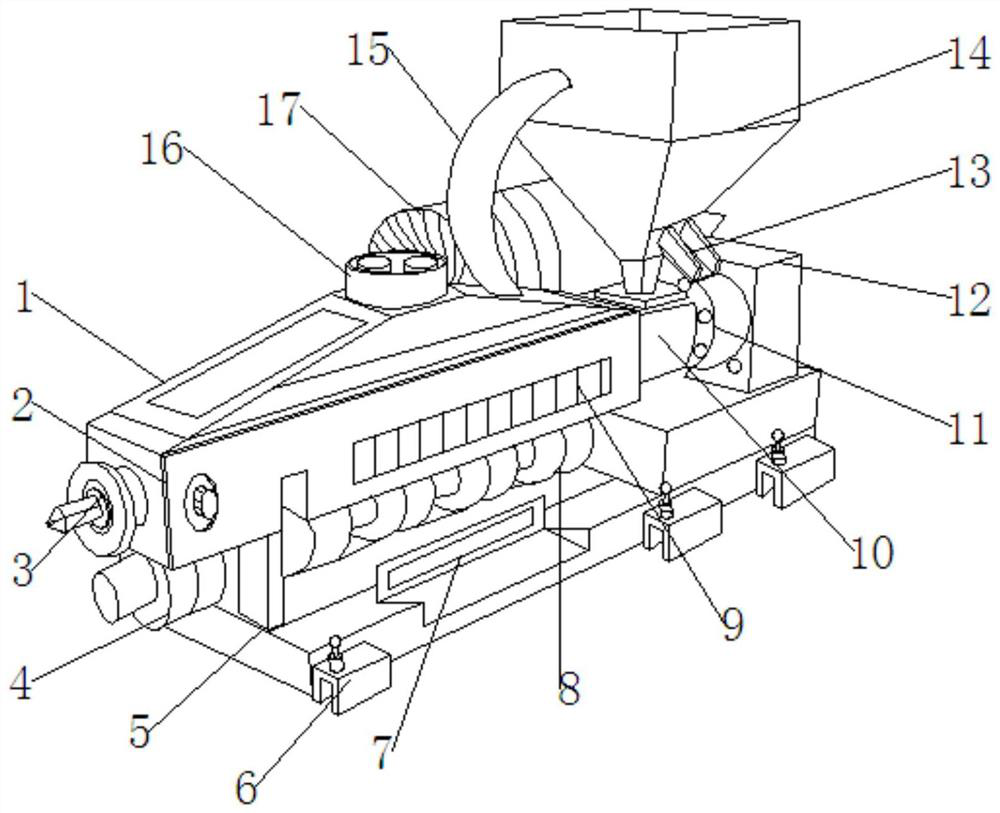

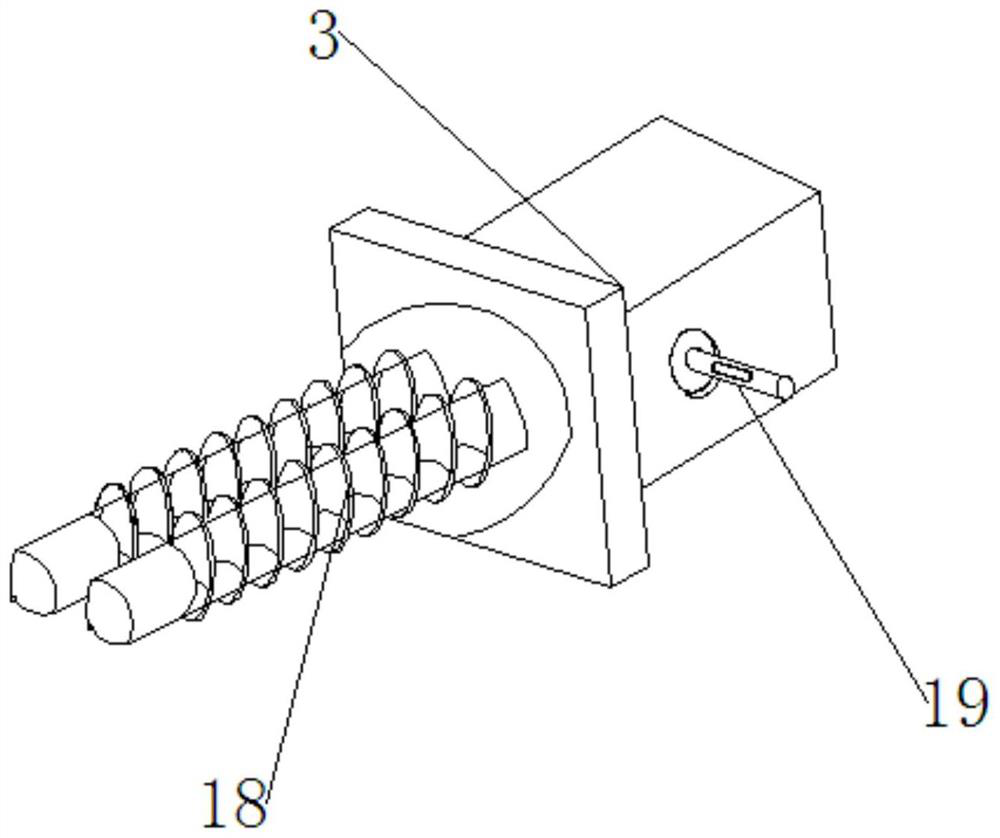

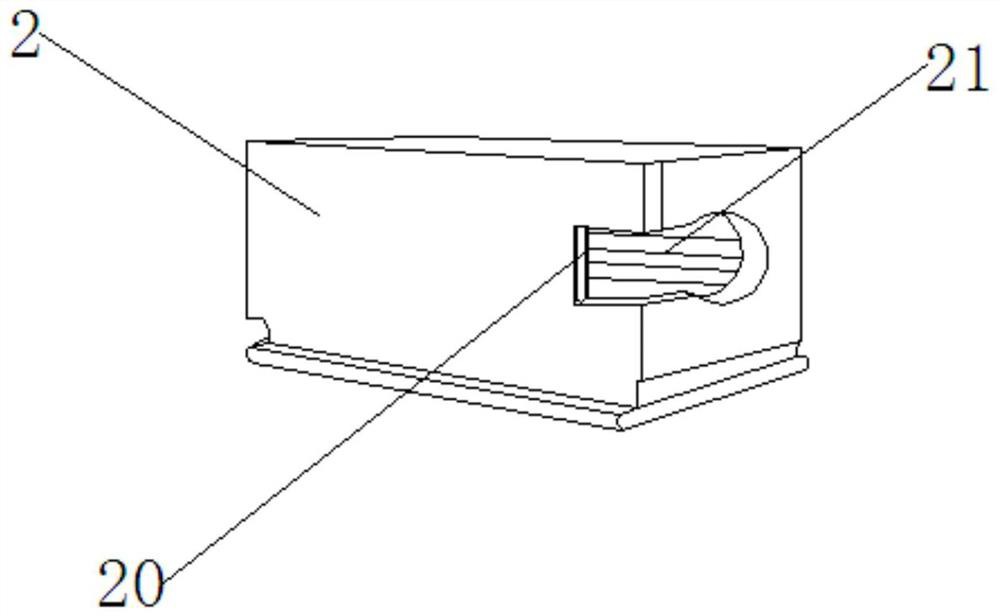

[0022] Example 1: See Figure 1-3 , the present invention provides a technical solution: a twin-screw plasticizing extruder with adjustable diameter for plastic modification process, including machine body 1, extrusion chamber 2, extrusion screw 3, discharge pipe 4, machine support Seat 5, installation block 6, discharge groove 7, storage bin 8, cooling plate 9, feed cylinder 10, transmission shaft 11, controller 12, discharge hopper 13, upper hopper 14, through pipe 15, through liquid tank 16, Power motor 17, parallel twin-screw rod 18, adjustment shaft 19, coolant through pipe 20 and built-in oil tank 21, the bottom end of machine body 1 is provided with machine support 5, and the side end of machine support 5 is provided with installation block 6, One end of the top of the machine support 5 is provided with a discharge groove 7, the middle part of the top of the machine support 5 is provided with a storage bin 8, one side of the storage bin 8 is provided with a discharge pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com