Three-dimensional needled carbon fiber preform forming production equipment and processing method thereof

A carbon fiber prefab, three-dimensional technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of poor discharge effect, difficult removal, and poor processing effect of equipment, so as to improve the discharge effect and improve the processing effect. , The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

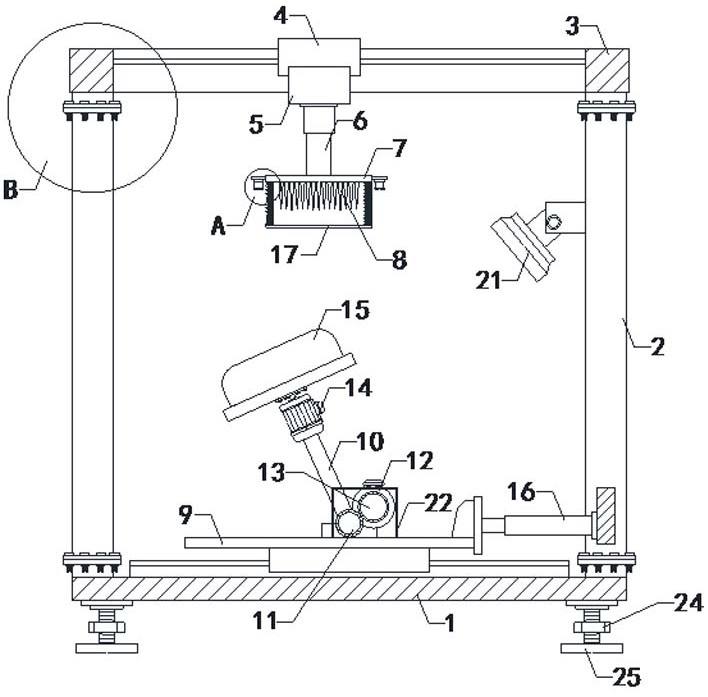

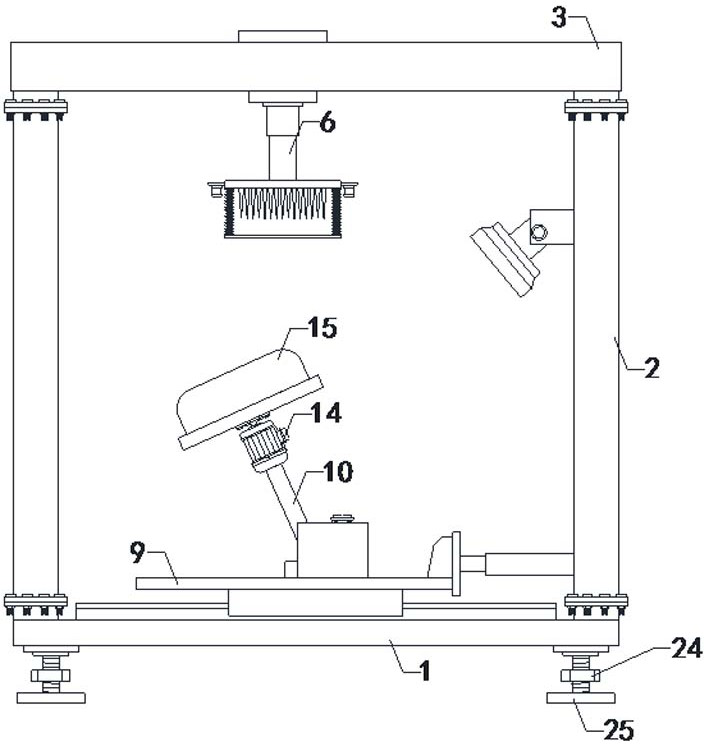

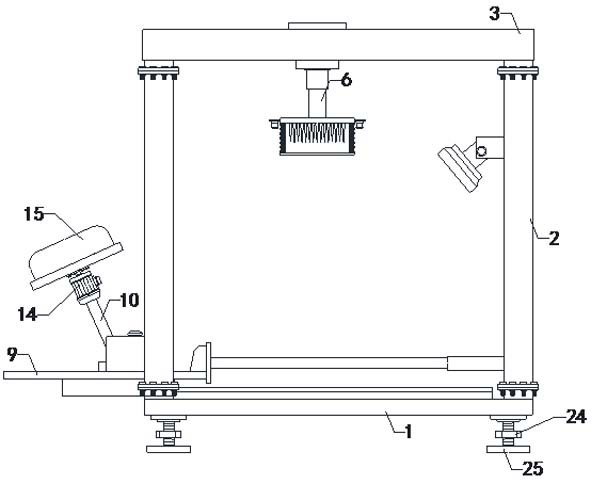

[0023] Such as Figure 1 to Figure 7 As shown, the processing method and production equipment for forming a three-dimensional needle-punched carbon fiber preform of the present invention include a base 1, a plurality of sets of supports 2, a top plate 3, a transverse slider 4, a longitudinal slider 5, a first hydraulic cylinder 6, a support Plate 7, several needles 8, workbench 9, support bar 10, first gear 11, first motor 12, second gear 13, second motor 14, supporting mold 15 and second hydraulic cylinder 16, multiple groups of supports 2 The bottom ends are all connected with the top of the base 1, the tops of the multiple groups of brackets 2 are connected with the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com